Contaminated soil/sediment remediation device

A technology for polluting soil and sediment, which is applied in the field of contaminated soil-sediment remediation devices, and can solve the problems of secondary pollution and low remediation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

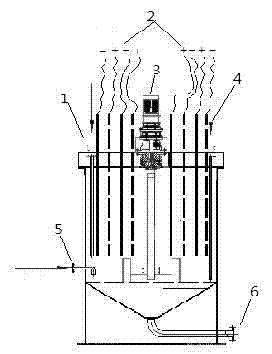

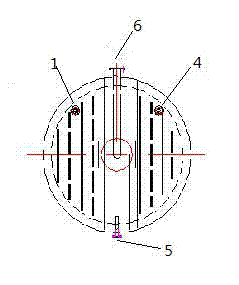

[0023] The core component of the polluted soil-sediment remediation device of the present invention is the EF-Feox reactor. The EF-Feox reactor includes a reagent inlet 1, an electrode 2, a stirring motor 3, a wastewater-sediment inlet 4, a reflux inlet 5 and an outlet 6. When the device starts to operate, the polluted soil and waste water are added to the EF-Feox reactor from the waste water-sediment inlet 4, and the treatment agent is added from the agent inlet 1 at the same time, then the power supply and the stirring motor 3 are turned on to start processing, and the outlet 6 is opened after a period of time , A part of the treated soil is discharged, and the other part is returned to the EF-Feox reactor through the reflux inlet 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com