Open type intelligent milling system and milling method based on same

A milling and open technology, applied in the field of machining, can solve the problems that affect the efficiency of CNC machining, the key parameters cannot be adjusted in real time, and the machining parameters cannot maintain the machining target, etc., and achieve the effect of increasing intelligent features.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

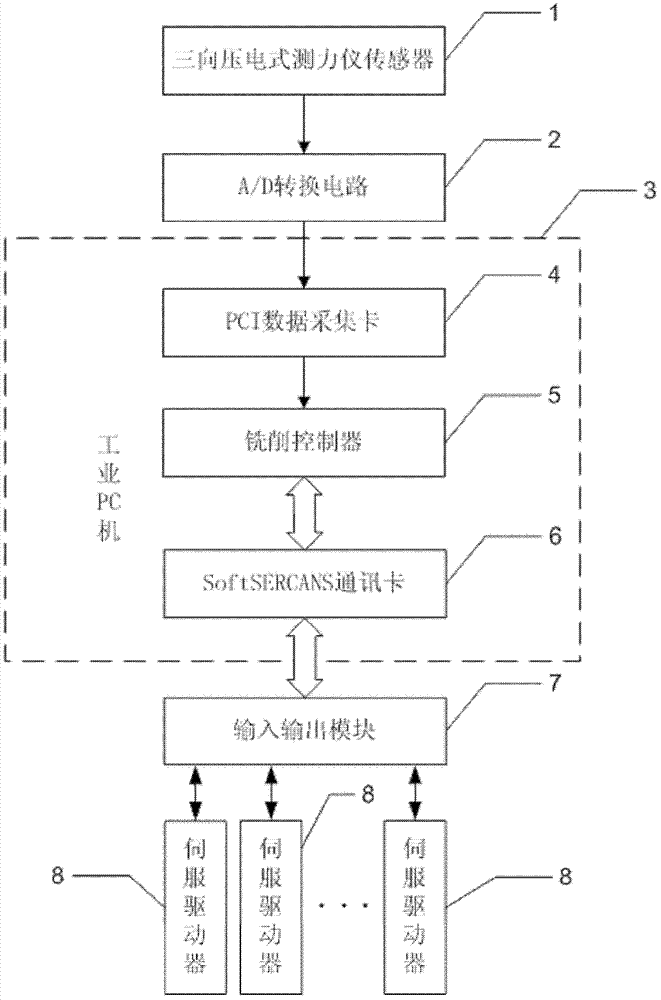

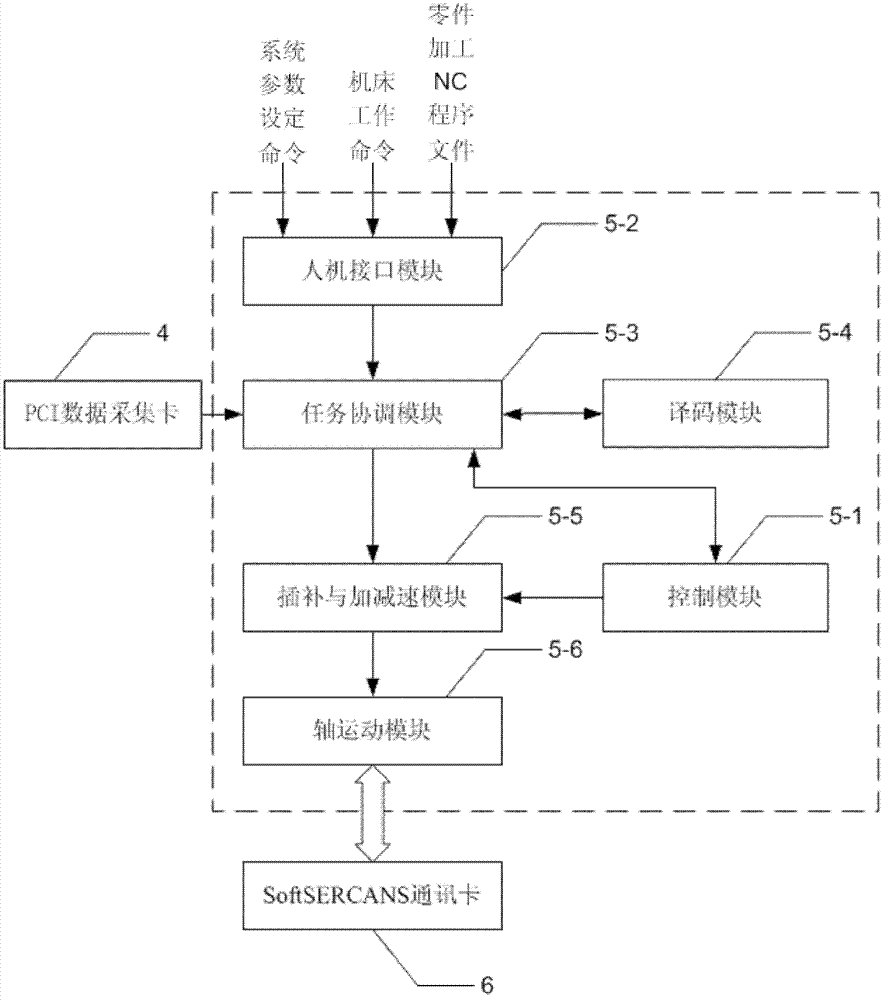

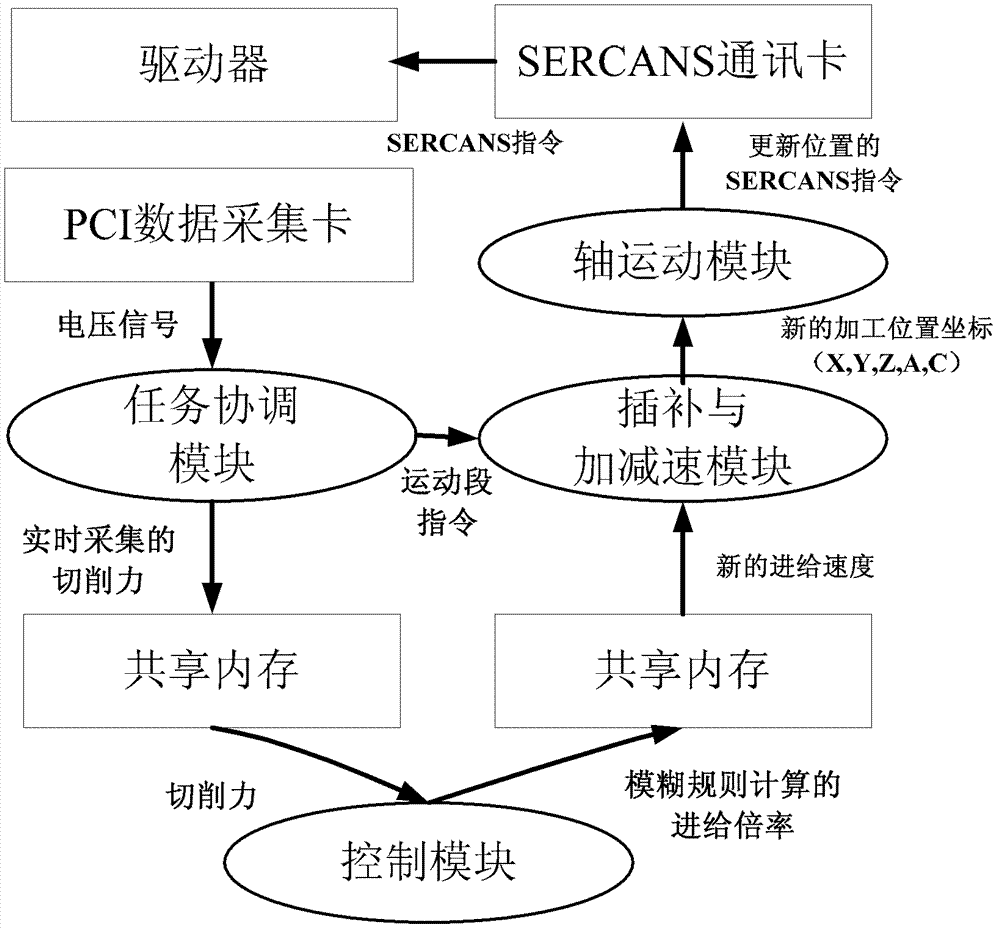

[0029] Specific implementation mode 1: the following combination figure 1 To explain this embodiment, the open intelligent milling processing system described in this embodiment includes a three-way piezoelectric force gauge sensor 1, an A / D conversion circuit 2, an industrial PC 3, a PCI data acquisition card 4, and a milling control Device 5, SoftSERCANS communication card 6, I / O module 7 and n servo drives 8, where n is a natural number greater than 1,

[0030] PCI data acquisition card 4, milling controller 5 and SoftSERCANS communication card 6 are set on industrial PC 3.

[0031] The three-way piezoelectric force gauge sensor 1 collects the cutting force generated by the interaction between the workpiece and the tool. The signal output terminal of the three-way piezoelectric force gauge sensor 1 is connected to the input terminal of the A / D conversion circuit 2. A / The output end of the D conversion circuit 2 is connected to the input end of the PCI data acquisition card 4, t...

specific Embodiment approach 2

[0036] Specific implementation manner 2: This implementation manner further illustrates the implementation manner. The three-way piezoelectric force gauge sensor 1 adopts the 9257B force gauge produced by Kistler.

specific Embodiment approach 3

[0037] Specific implementation manner 3: This implementation manner further illustrates the implementation manner 1. The PCI data acquisition card 4 adopts the PCI1710 data acquisition card produced by Taiwan Advantech.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com