Rotation positioning mechanism and rotation technology board device with same

A technology of positioning mechanism and process board, which is applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of low positioning reliability, weakened elastic force, insufficient tightening force of the rotating positioning mechanism, etc., so as to reduce the hidden danger of deformation. , The positioning is reliable, and the effect of solving the difficulty of card insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

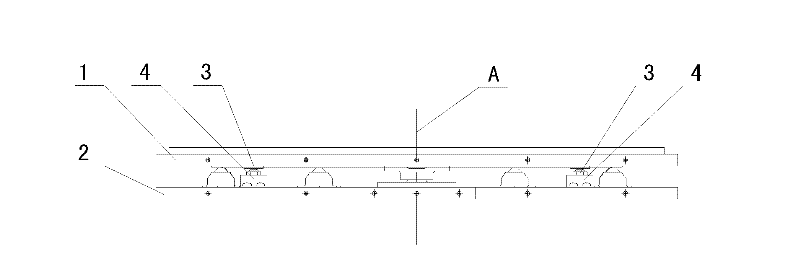

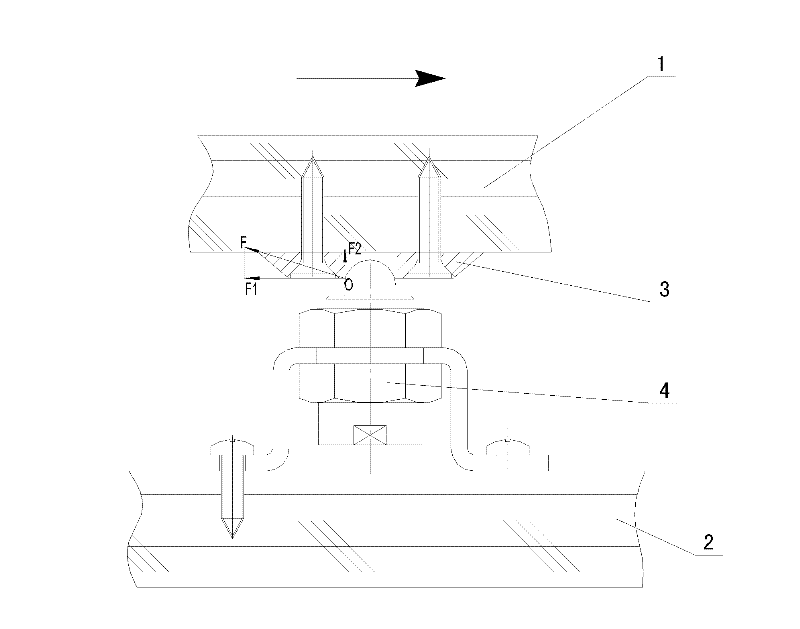

[0035] The rotary process board device of the present invention is mainly composed of a first process board 1, a second process board 2 and a rotary positioning mechanism. The first process board 1 and the second process board 2 are stacked up and down, and the first process board 1 can be wound around The axis of rotation A rotates relative to the second process plate 2 .

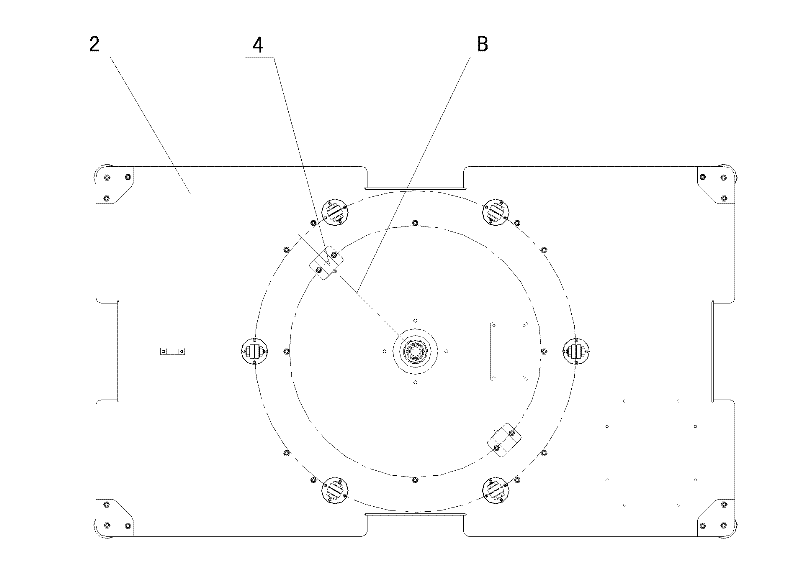

[0036] like image 3 , 4 As shown, the rotation positioning mechanism consists of 8 first positioning components 3 that are evenly distributed on the first process board 1 in the circumferential direction with the rotation axis A as the center A second positioning assembly 4 is formed. The first positioning assembly 3 and the second positioning assembly 4 cooperate with each other in a plane perpendicular to the rotation axis, and the second positioning assembly 4 is located outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com