Heavy-load double-layer-loaded container rail wagon

A technology for railway wagons and containers, applied in the field of railway wagons, can solve the problems of difficulty in double-layer loading and waste of transport capacity, and achieve the effect of improving transport capacity and increasing the strength of the car body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

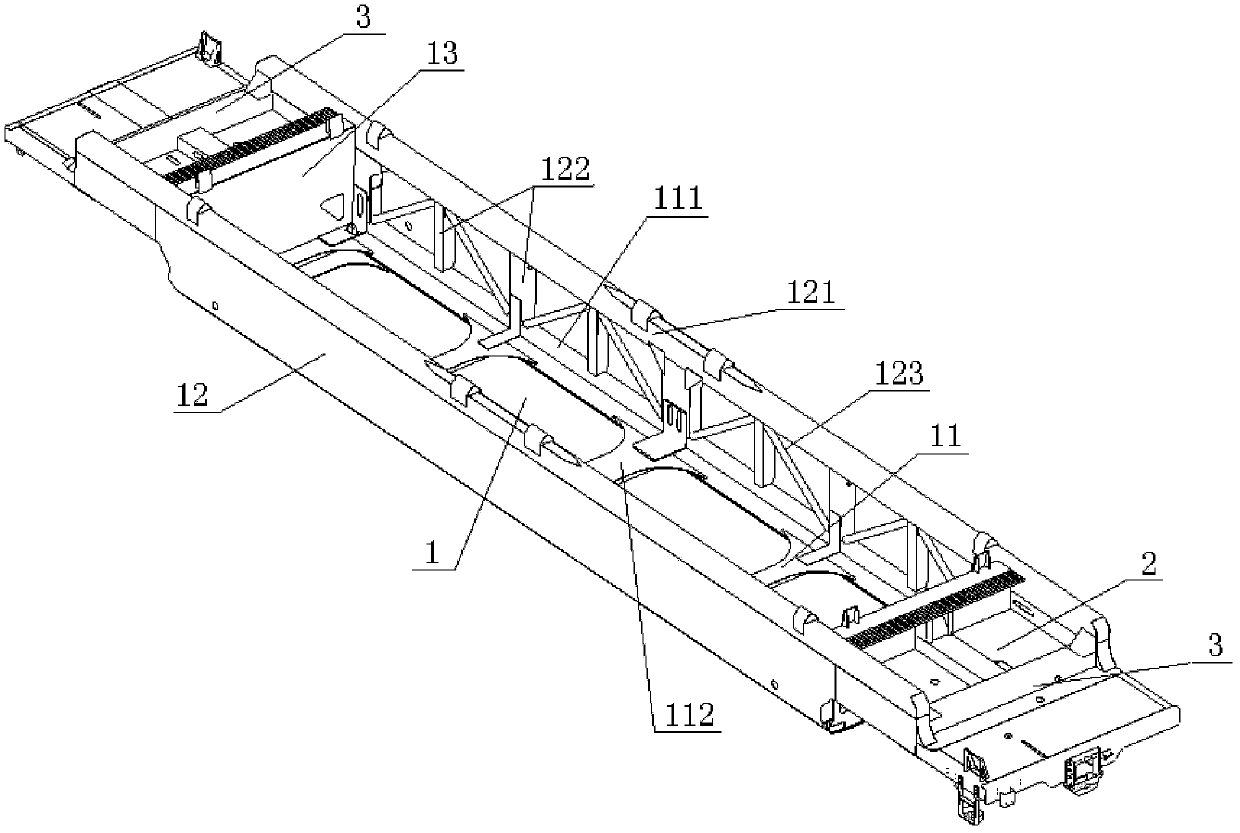

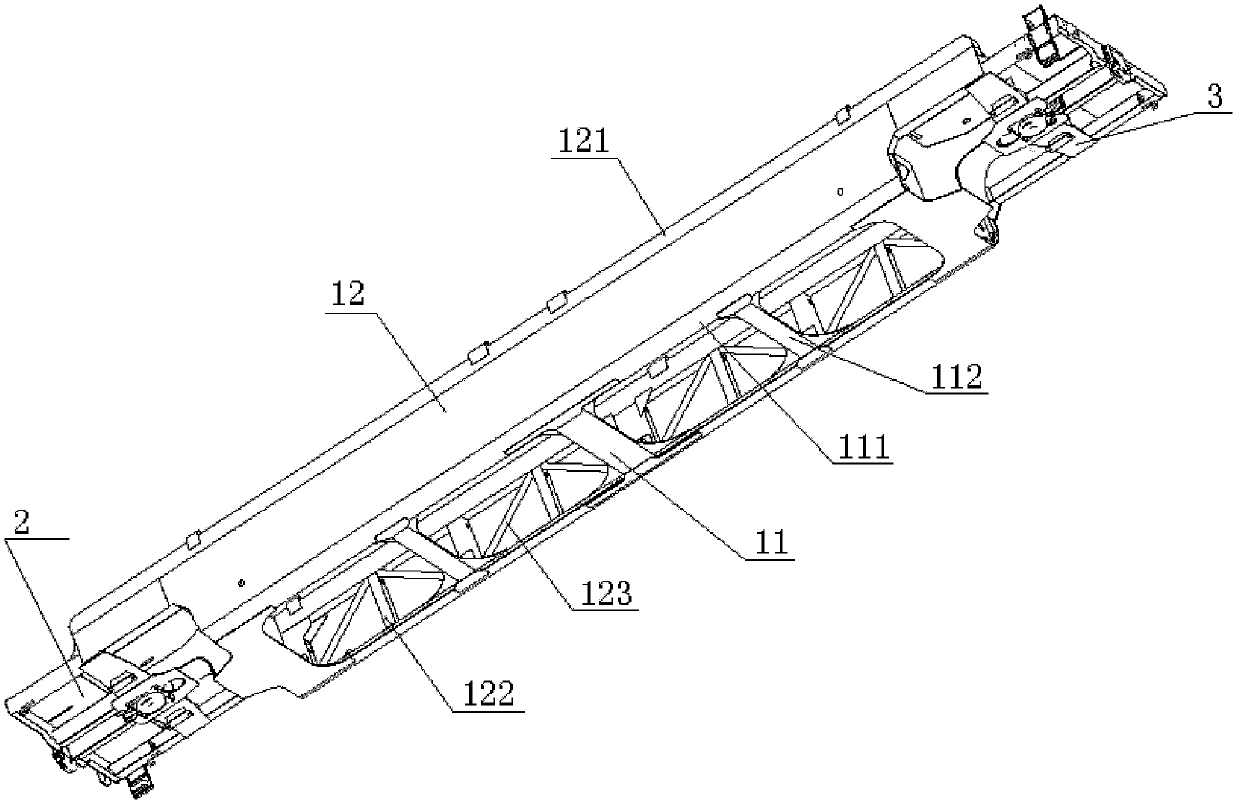

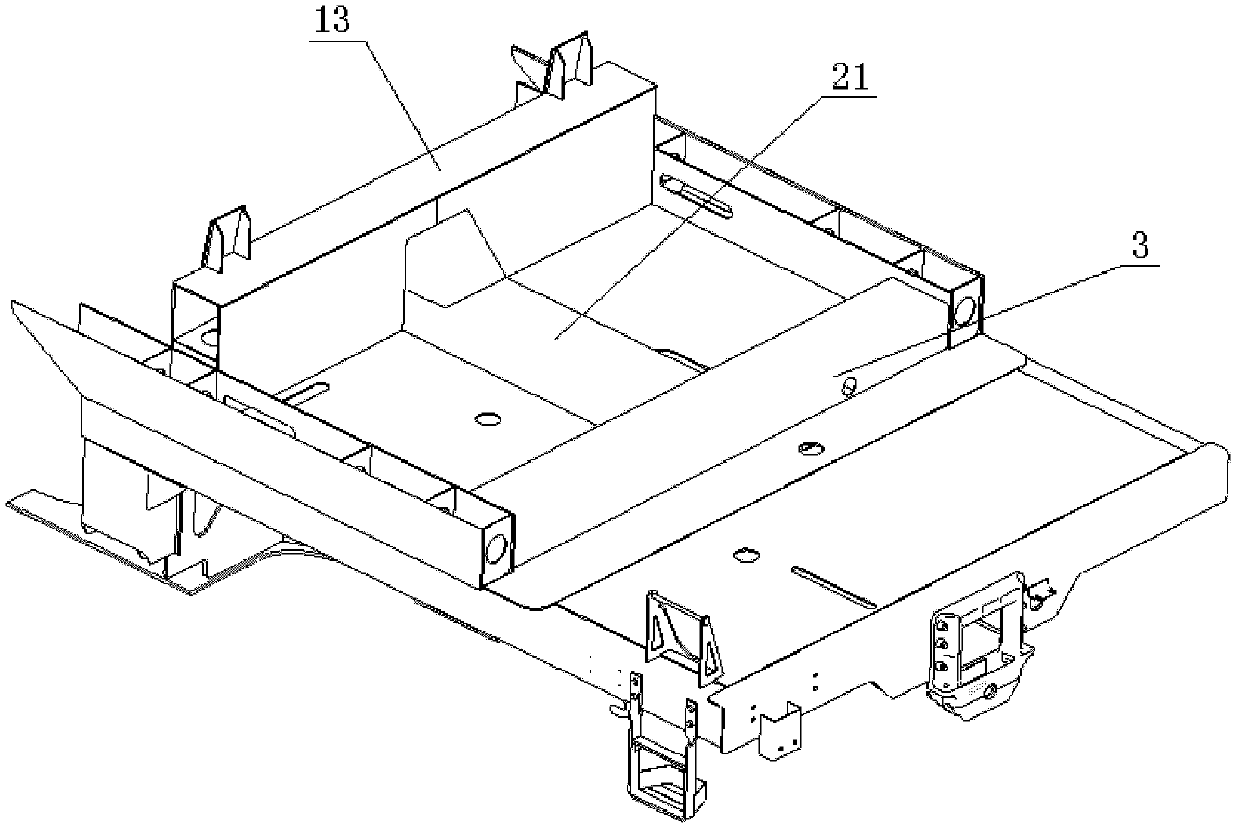

[0017] Such as figure 1 , figure 2 As shown, the present invention includes a loading part 1 and an end chassis 2, wherein the loading part 1 adopts the form of a drop hole, the loading part 1 includes a drop hole chassis 11, side walls 12 and end walls 13, and the size of the drop hole chassis 11 It should be able to guarantee loading of two 20ft containers or one 40ft container. The drop hole underframe 11 includes two longitudinally arranged side beams 111, and section steel or steel plates are used as transverse connecting beams 112 to connect the side beams 111. An inverted convex side wall 12 is welded and assembled on both sides of the drop hole chassis 11, and the two ends of the side wall 12 extend above the ends of the corbel 3 to bear the longitudinal and vertical loads of the vehicle. The lower part of the side wall 12 is welded with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com