Plastic part quantitative detection device

A technology for quantitative detection and plastic parts, applied in the field of quantitative detection devices for plastic parts, can solve problems such as affecting work efficiency, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

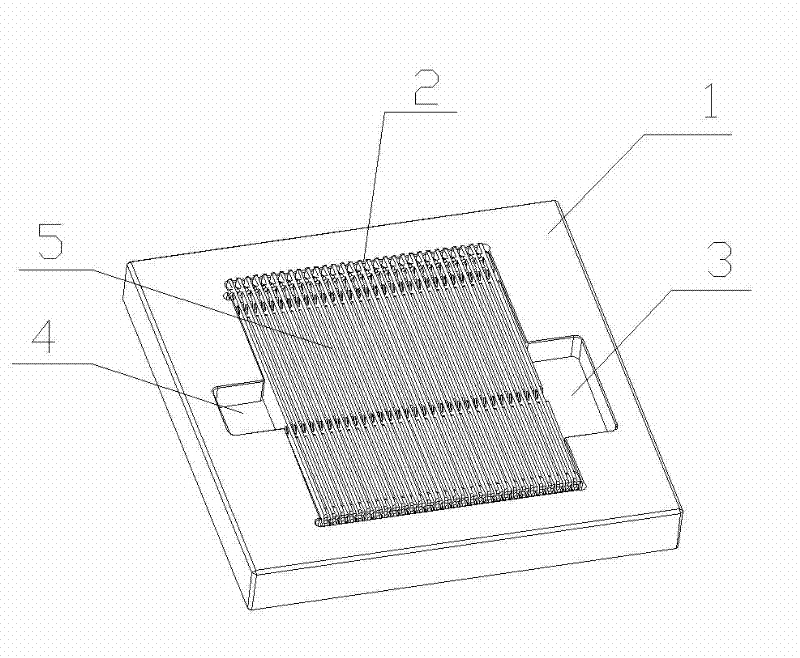

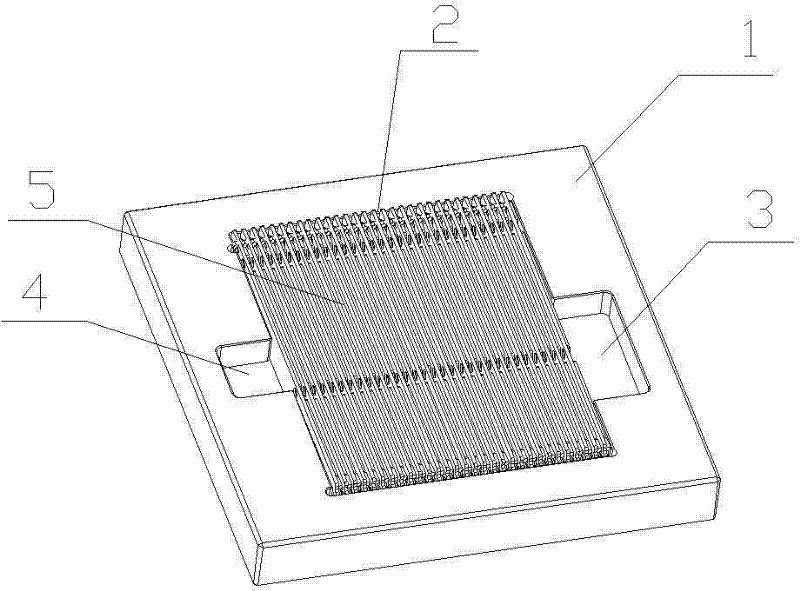

[0008] See figure 1 , the present invention includes a quantitative jig 1, the body of which is a cuboid, and a cavity 2 is arranged in the middle of the quantitative jig 1, the cavity 2 is a rectangular sinker, and the size of the rectangular sinker = the number of finished plastic parts × the thickness of the finished plastic part + safety amount (0.5-1mm), the pick-up slots are respectively arranged on both sides of the rectangular sinker symmetry, the pick-up slots are respectively a large pick-up slot 3 and a small pick-up slot 4, the cross-sectional shape of the rectangular sinker and the stack The shape of the finished plastic parts is matched to avoid the finished plastic parts from being damaged by rubbing against the cavity 2 during putting in and taking out. The material of the quantitative fixture 1 is bakelite, and 5 in the figure is the finished plastic part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com