Working process of intelligent distribution control system for material flow conveying and sorting

A control system and intelligent distribution technology, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as uneven distribution, achieve accurate distribution, optimize configuration, and increase the tracking success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

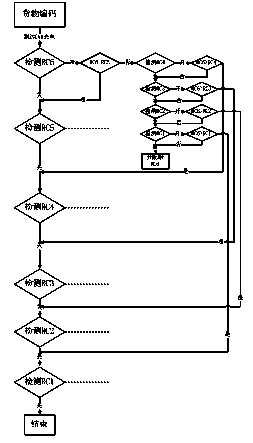

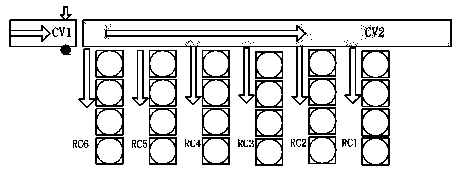

[0013] The invention includes a conveying line, a transfer device, and a controller. Several sorting ports are arranged on the branches of the conveying line, and an induction device connected to the controller is arranged on the conveying line, and one of the induction devices is connected to the controller. The object coding program module, the object coding program module is used to generate a number for the goods, and distribute the goods to the sorting port with the least current goods through the detection of the controller, and the controller will compare the goods number and the corresponding sorting The channel number of the port is stored in a memory; other sensing devices are respectively set at each sorting port, and the multiple sensing devices are connected to the logic control program module in the controller, and the logic control program module is used when the goods pass through At the sorting port, check whether the current sorting port corresponds to the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com