Telescopic truss arm and engineering machinery

A technology of construction machinery and truss arms, which is applied to cranes and other directions, can solve problems such as unfavorable manpower and time, and cumbersome operations, and achieve the effects of low price, good production process, and increased selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

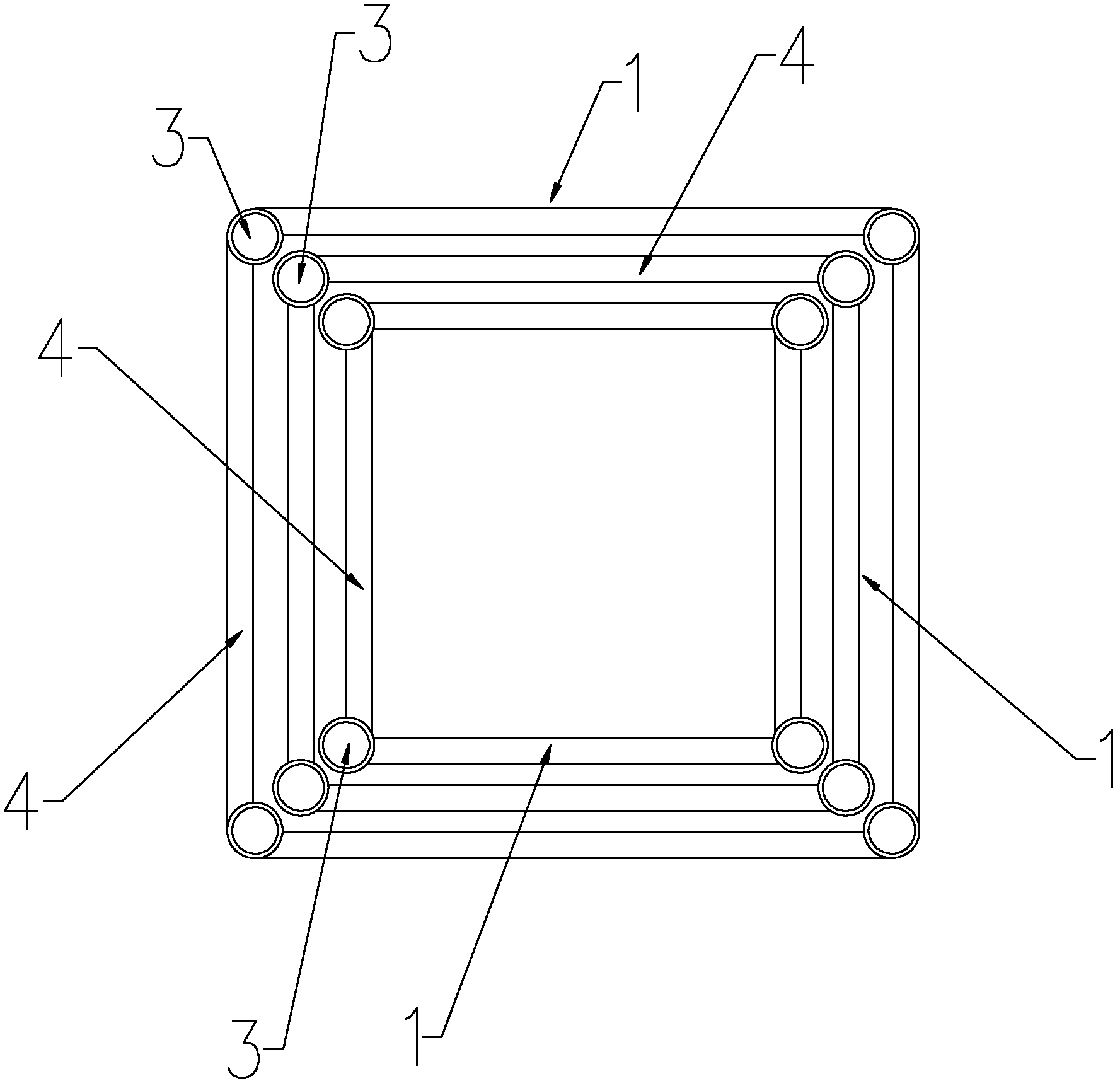

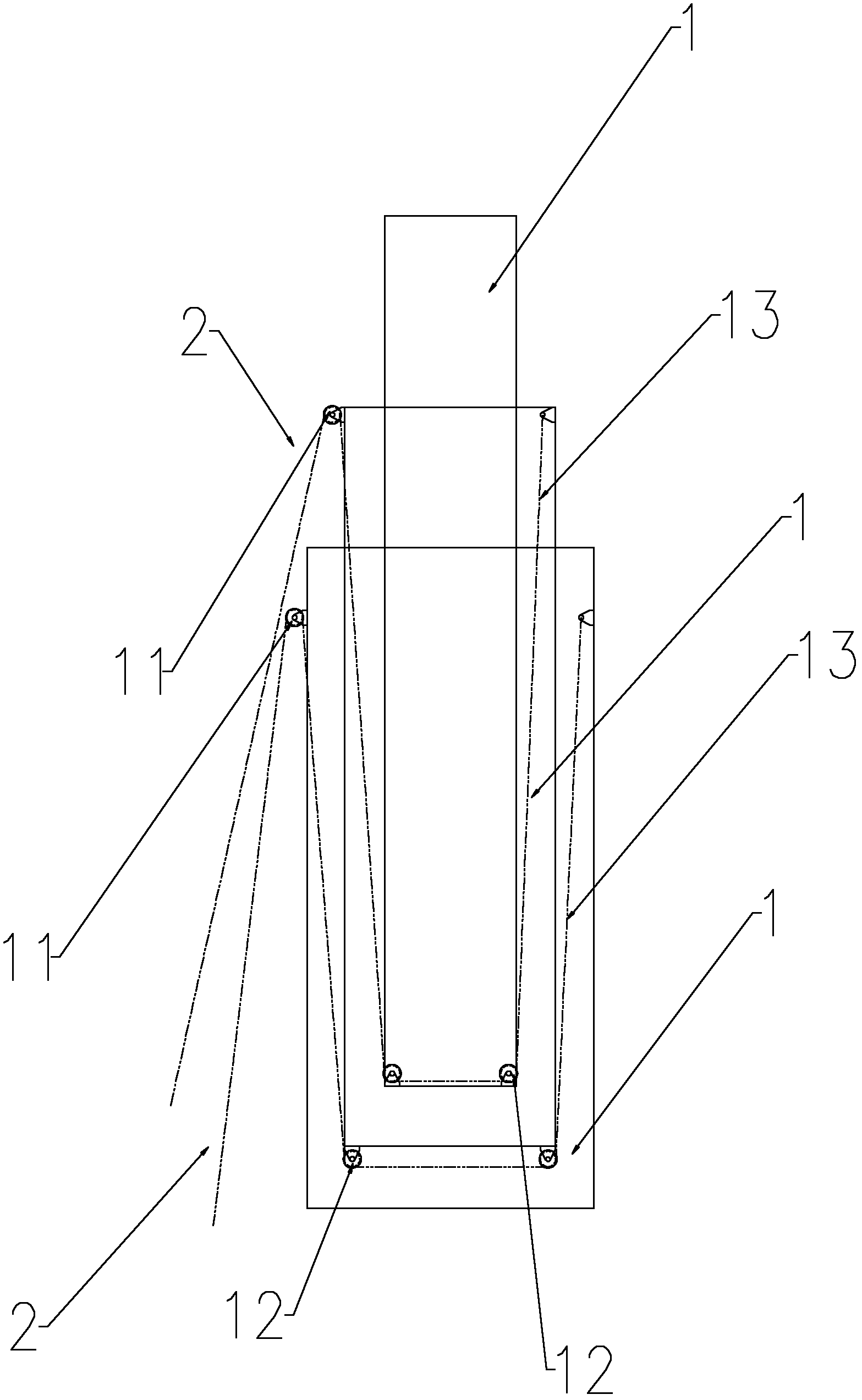

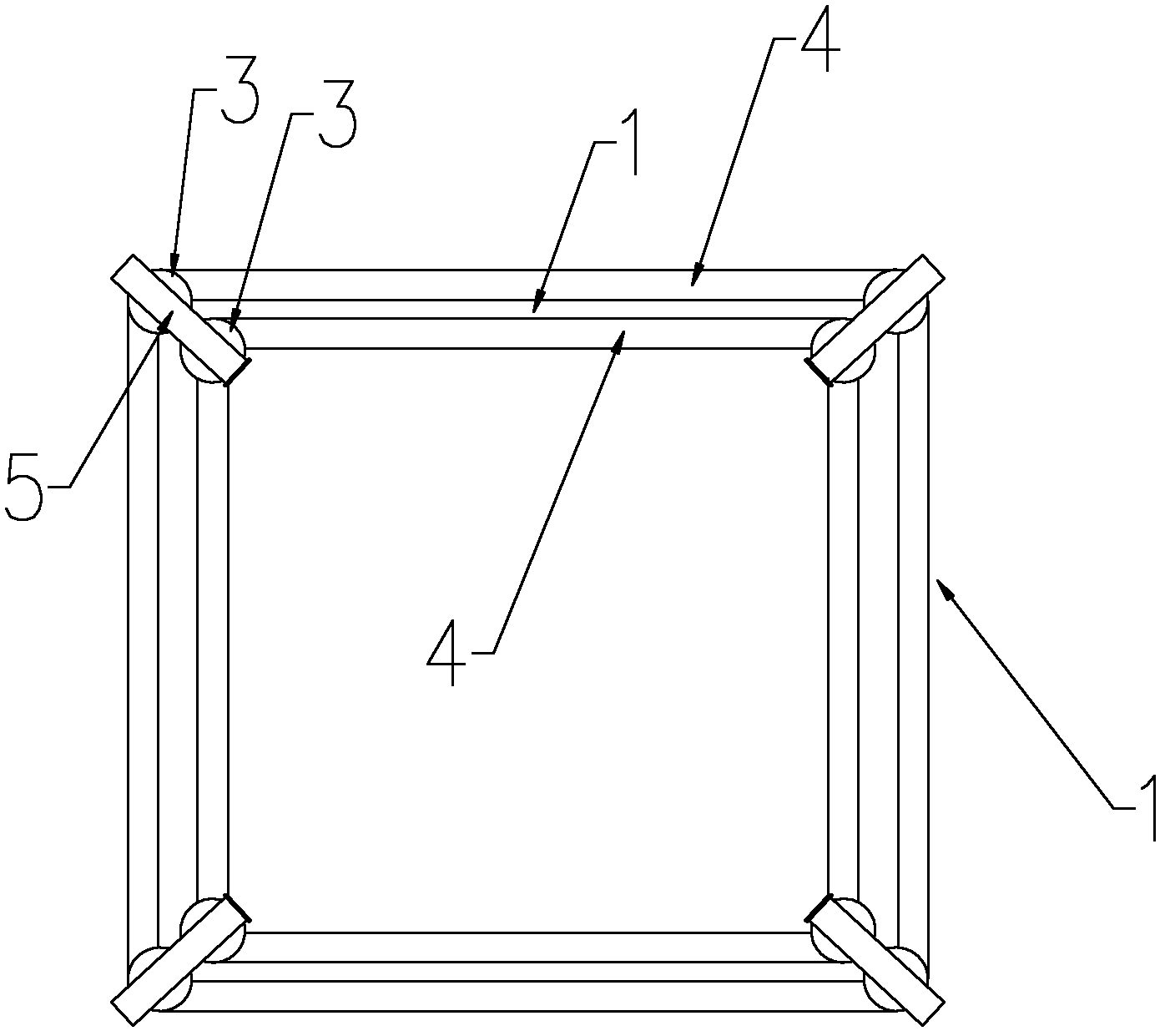

[0036] The telescopic mechanism 2 can take various suitable forms, such as figure 2As shown, according to a preferred embodiment of the present invention, the telescopic mechanism 2 includes a pulley block and a wire rope 13, the pulley block includes a first pulley 11 and a second pulley 12, and the first pulley 11 is fixed to two adjacent The upper part of one side of the outer jib section 1 among the jib sections 1, the second pulley 12 is fixed on the bottom of the inner jib section 1 among the two adjacent jib sections 1, and one end of the steel wire rope 13 is fixed to the The other end of the steel wire rope 13 is wound around the bottom of the second pulley 12 and the top of the first pulley 11 in turn and stretches out from the first pulley 11 . In this way, the expansion and contraction of each boom can be controlled by an independent winch, which has high reliability and good safety.

[0037] There may be two second pulleys 12 , and the two second pulleys 12 may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com