Method for replacing catalyst in formaldehyde reactor during productive process of paraform

A production process and catalyst technology, applied in chemical instruments and methods, organic chemistry, carbon-based compound preparation, etc., can solve the problems of consuming manpower and material resources, increasing production costs, and catalyst loss, achieving good results, saving regeneration costs, and improving The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

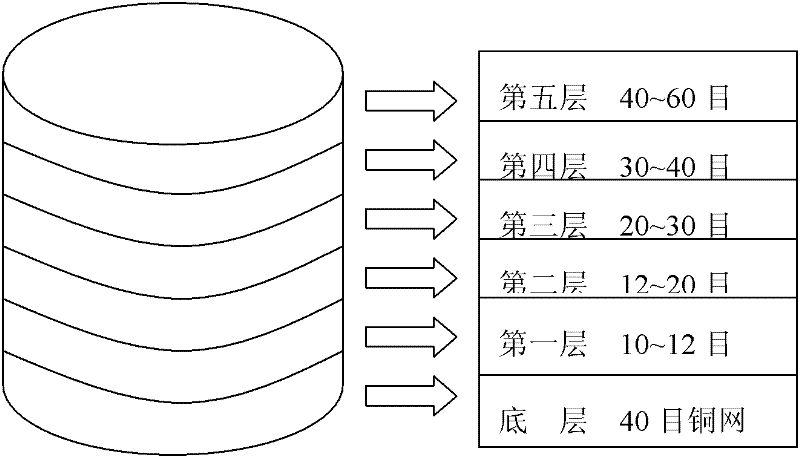

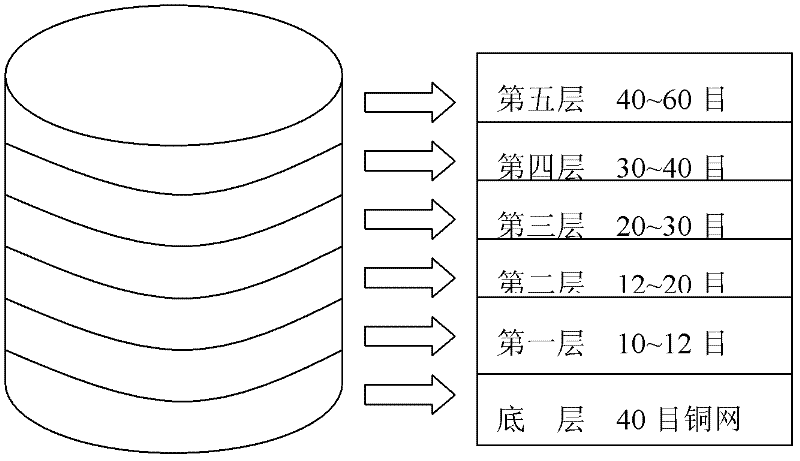

Method used

Image

Examples

Embodiment 1

[0014] (1) When replacing the catalyst for the first time, scrape off all the catalysts whose catalytic effect has been significantly reduced, until the bright white electrolytic silver is exposed; (2) Lay the top layer with a new electrolytic silver catalyst , The gaps at the edge of the reactor are filled with old catalysts and then compacted.

[0015] After testing: after replacing a layer of catalyst, the oxygen content in the exhaust gas at the top of the formaldehyde absorption tower is 200ppm, and the formaldehyde conversion rate in the formaldehyde reactor is above 90%; the formaldehyde sampling and analysis results of the formaldehyde reactor product show that the formic acid content is 100ppm, and the methanol content is 100ppm. It is 0.83%, and the content is normal, indicating that the activity of the catalyst is in the best state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com