Construction method for enabling rectangular pipe jacking machine to enter into tunnel in existing building

An in-building, rectangular pipe jacking technology, used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of increasing construction difficulties, inability to set up receiving wells, and bulky pipe jacking machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

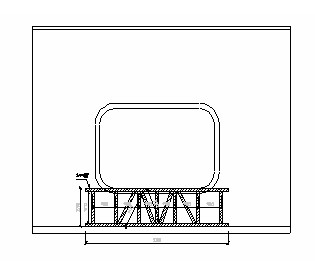

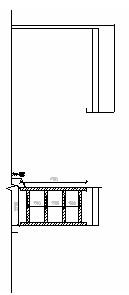

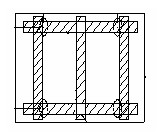

[0006] (1) Set up the tunnel receiving buffer platform in the built building at the entrance, (2) Set up the cutter head lifting point of the pipe jacking machine in the built building at the entrance, (3) Dig the pipe before entering the hole Remove the hole door, (4) Adjust various parameters, enter the hole with the pipe jacking machine, (5) enter the hole with the rectangular pipe jacking machine, and seal the hole door, (6) Disassemble the cutter head, chest plate and internal equipment of the pipe jacking machine and remove them from the channel (7) Leave the casing of the pipe jacking machine in the channel. It is characterized in that: the step (1) is to set up a receiving buffer platform in the building that has entered the hole to relieve the impact force generated by the collapse of the soil when the pipe jacking machine enters the hole. The buffer platform is made of I20b I-beam For erection, a 2cm thick steel plate is laid on the surface of the platform, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com