LED light bar

A technology of LED light strips and light panels, applied in the field of lighting, can solve the problems of heat dissipation, light efficiency and waterproof, cleanliness needs to be improved, reduce the heat dissipation performance of the heat sink 110, limit the overall light efficiency of LED light strips, etc., to improve self-adaptation Cleaning performance, lateral width reduction, effects of pressure loss avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

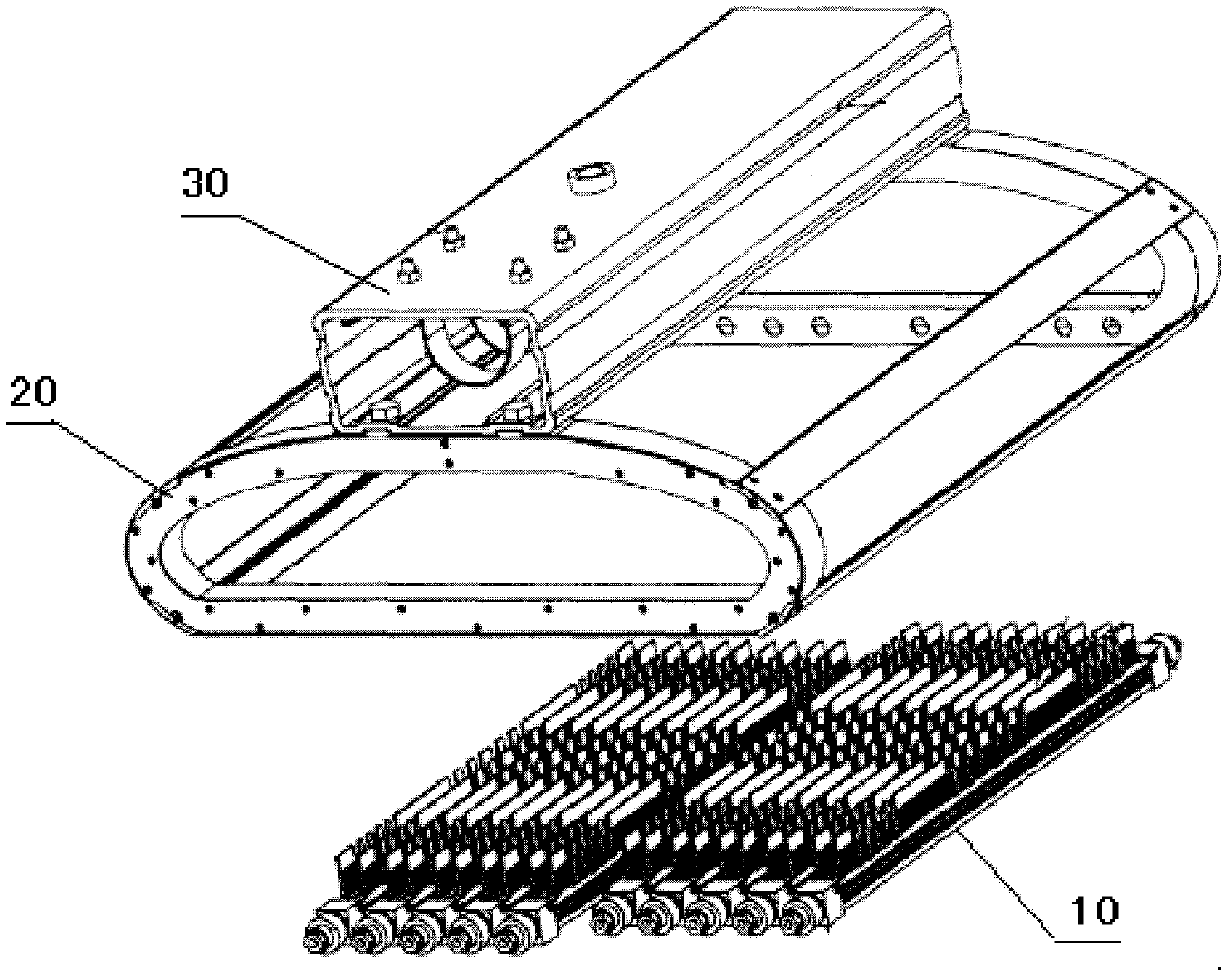

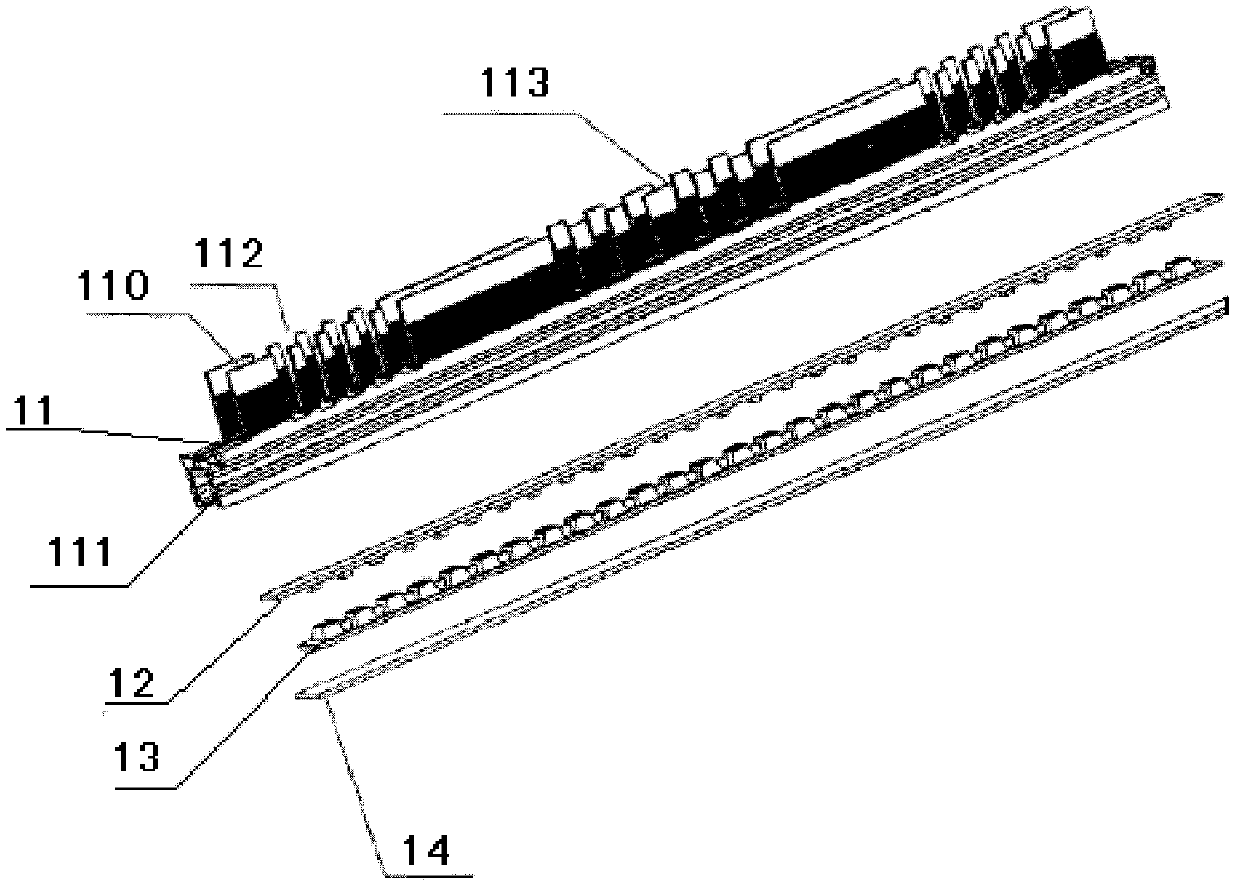

[0049] Such as Figure 4 , 5 As shown, the LED light bar of the present invention includes a heat dissipation bracket 201 , a light board 202 on which an LED light source 204 is fixed, and a semicircular light output cover 203 .

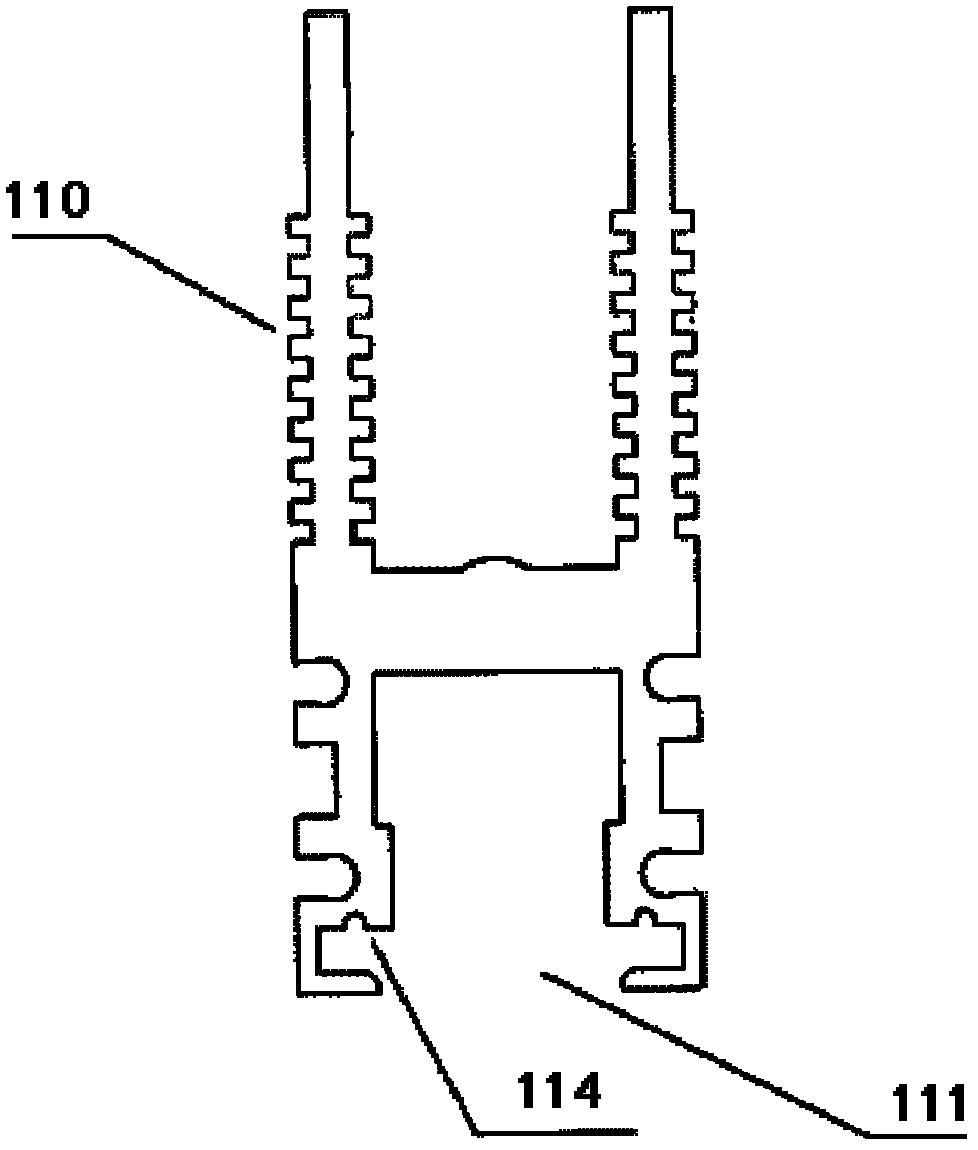

[0050] Such as Figure 6 As shown, the heat dissipation bracket 201 includes a heat dissipation groove 205 and a fixing bar 206. The heat dissipation groove 205 and the fixing strip 206 are designed in an integrated manner, and are made of a mixture of rare earth and aluminum, specifically composed of the following components by mass percentage:

[0051] Mg 0.4%~1%,

[0052] Si 0.7%~18%,

[0053] Mn 0.12%~0.2%,

[0054] Cr 0.12%~0.2%,

[0055] Cu 0.12%~0.2%,

[0056] Fe 0.12%~0.2%,

[0057] Ti 0.12%~0.2%,

[0058] Re 0.1%~0.2%,

[0059] Al balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com