Automatic corrugated pipe detection equipment and detection method

An automatic detection and bellows technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as inability to connect and automatic detection of bellows, and achieve the effect of reducing distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

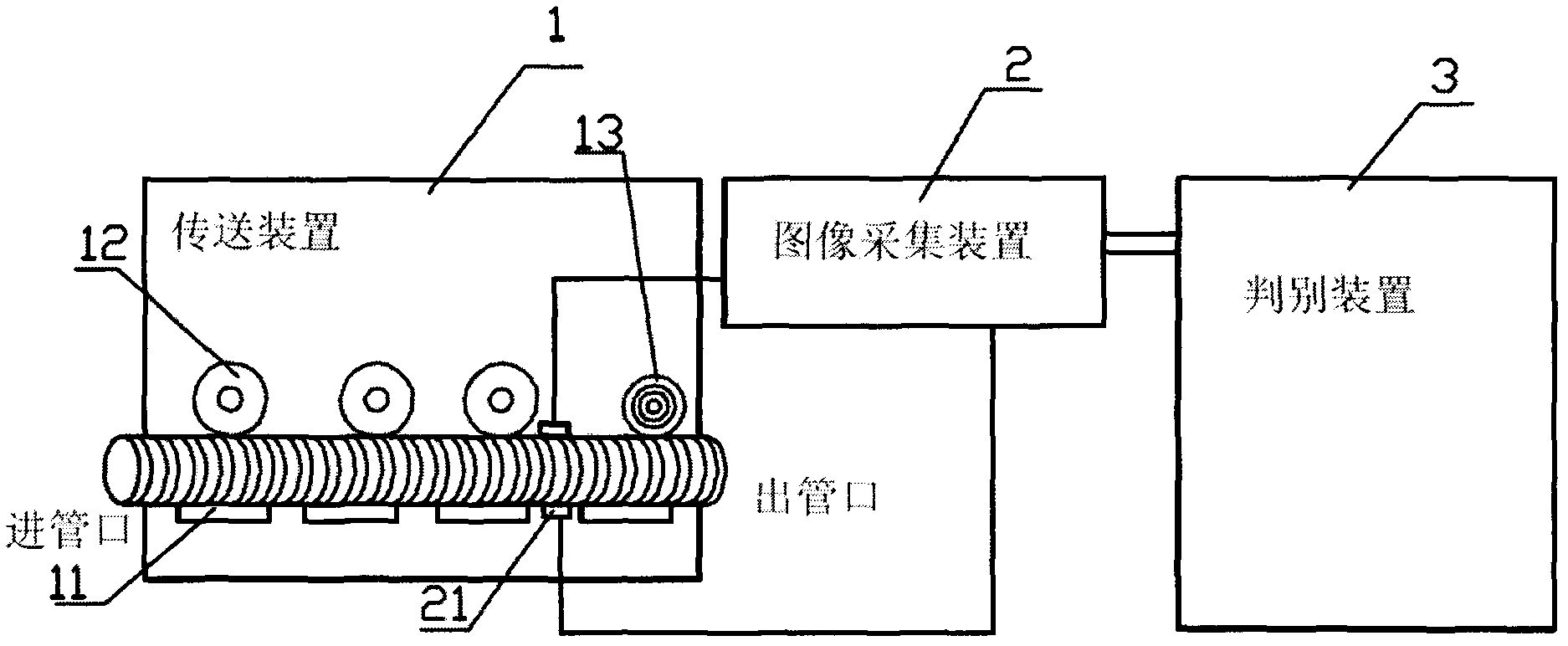

[0030] refer to figure 1 , The device of the present invention is generally composed of a transmission device 1, an image acquisition device 2, a discrimination device 3 and an outer shell of the device. Wherein, the outer casing of the device is provided with a pipe inlet hole and a pipe outlet hole (not shown in the figure). The corrugated pipe from the corrugated pipe production line will enter the conveying device 1 from the pipe inlet hole of the equipment, and output from the pipe outlet hole after being detected.

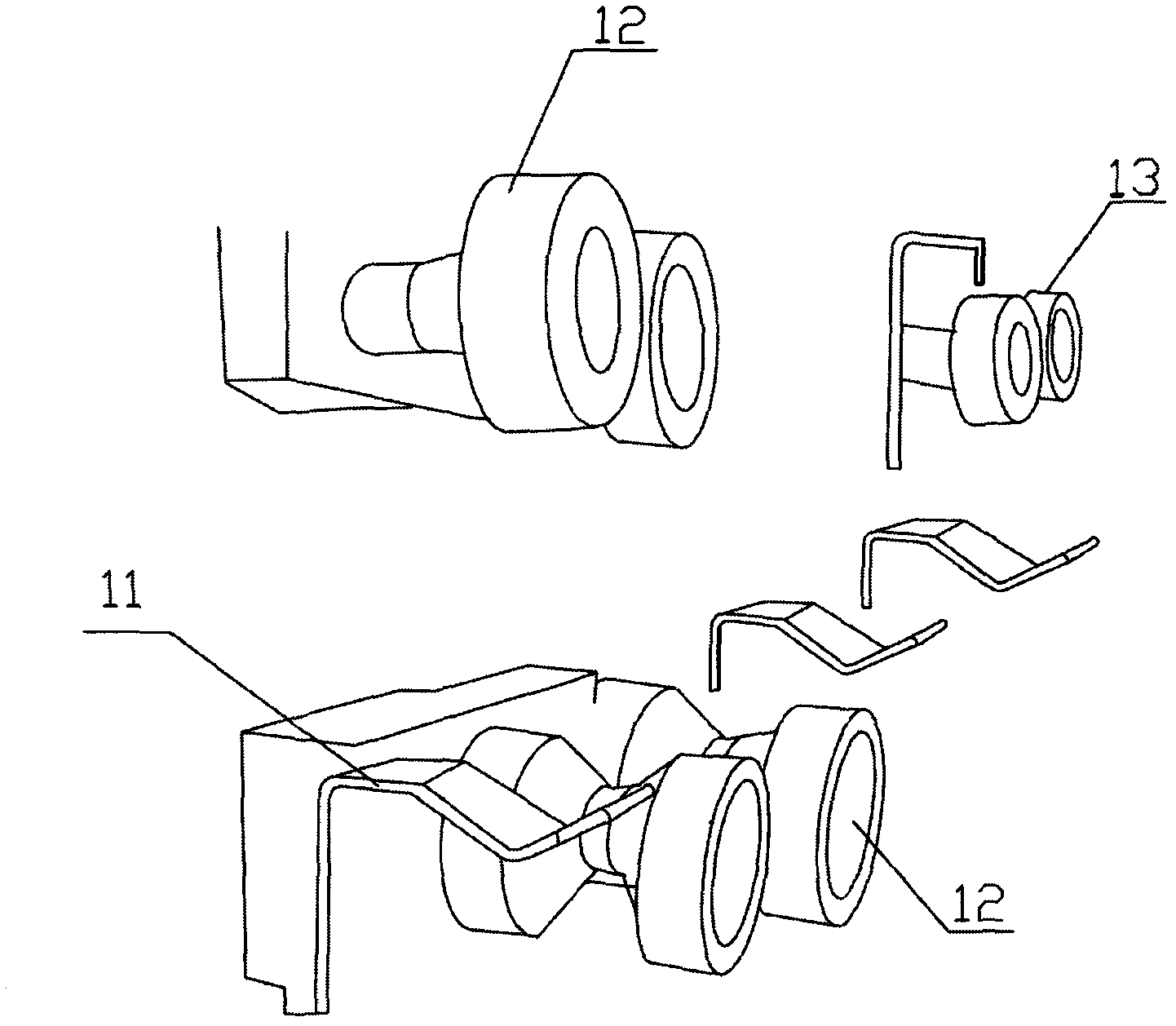

[0031] refer to figure 1 with figure 2 , The transmission device 1 is provided with guide rails 11 , elastic pressure rollers 12 and braking pressure rollers 13 . Wherein the guide rail 11 is composed of several V-shaped guide rail pieces. If an ordinary straight guide rail is used, the bellows will vibrate left and right during the movement, which is not conducive to image acquisition. The use of V-shaped guide rails can enable the bellows to be effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com