Horizontal wire rope fatigue testing machine

A technology of fatigue testing machine and steel wire rope, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as wire rope fatigue, and achieve the effect of low price and easy popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

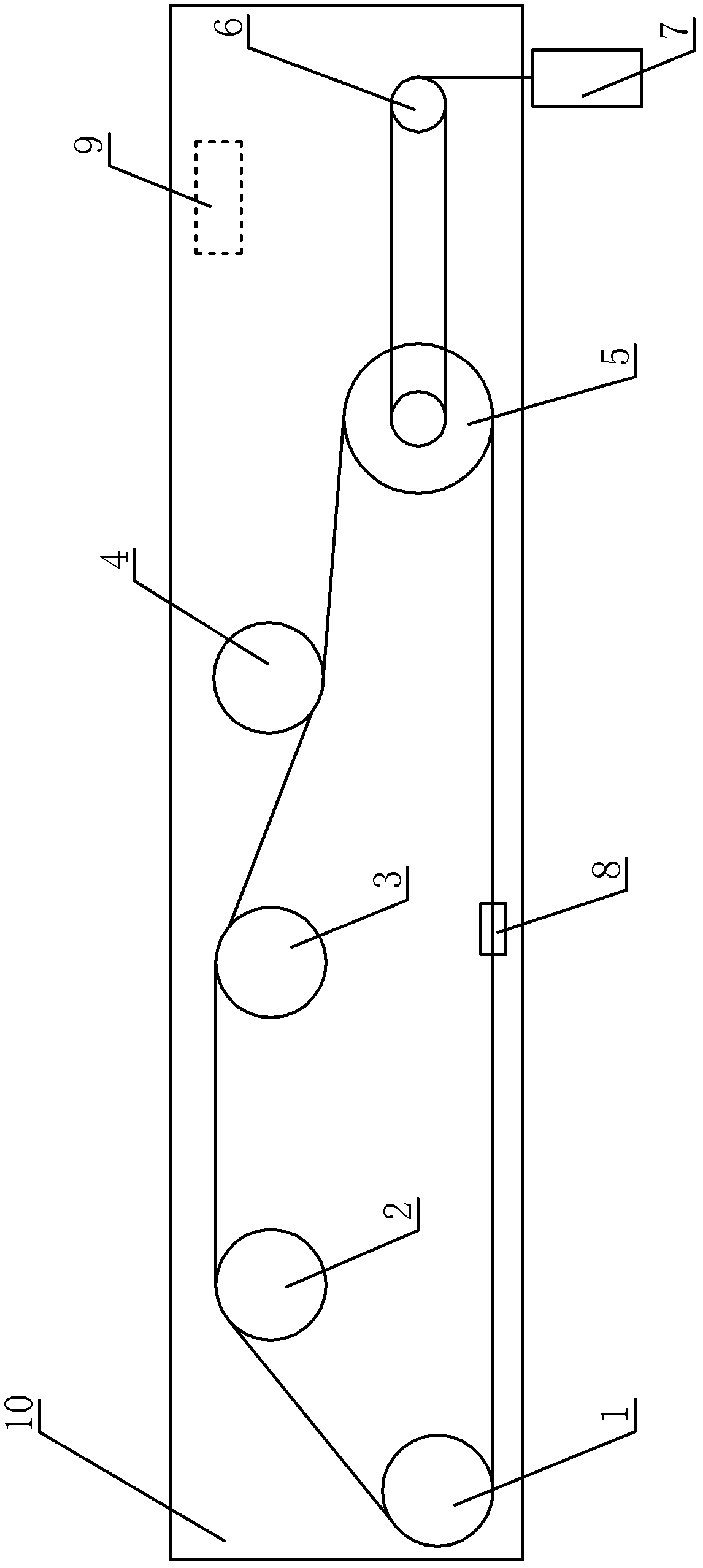

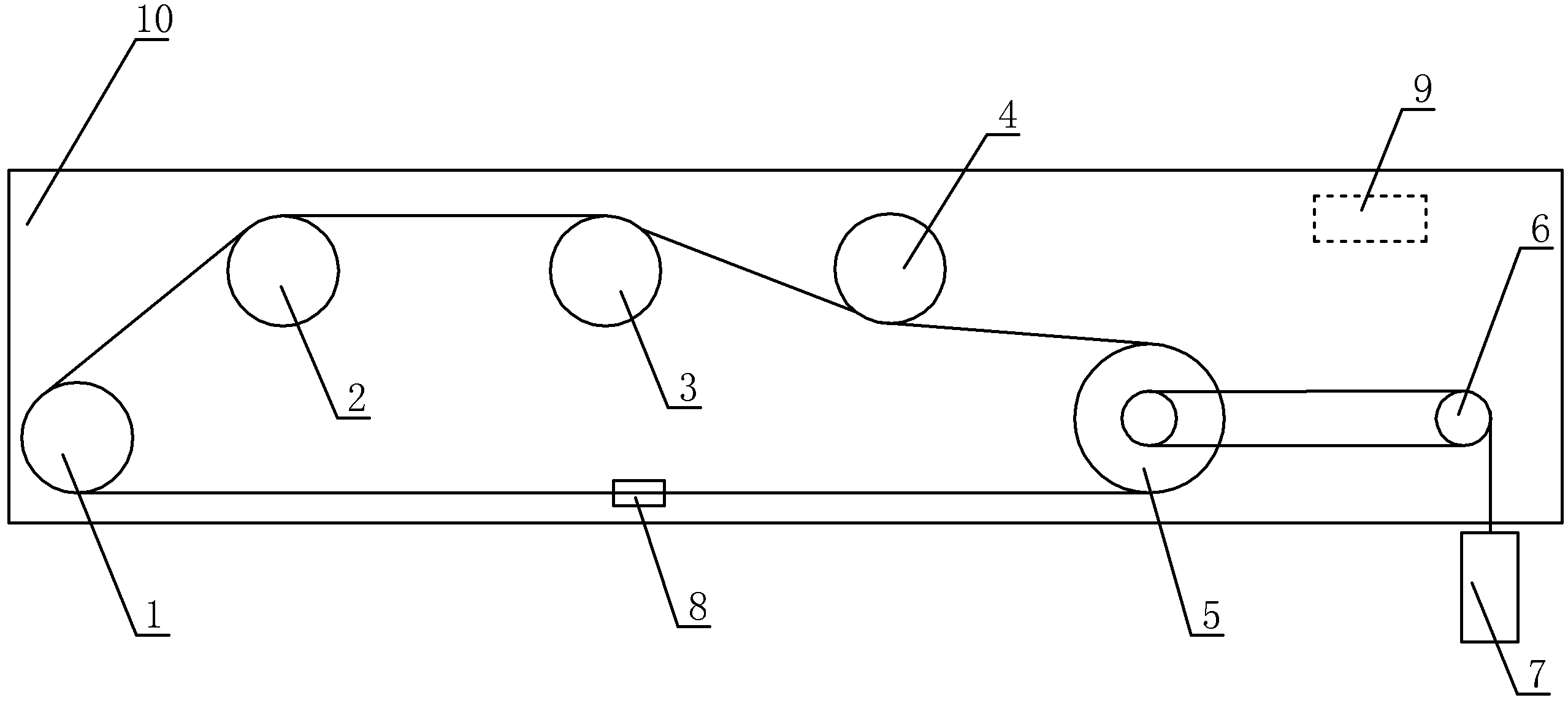

[0013] Please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of the horizontal steel wire rope fatigue testing machine of the present invention. In this embodiment, a horizontal steel wire rope fatigue testing machine includes a working wheel 3 installed on the body 10, the working wheel 3 is connected to a driving motor, and the driving motor It is electrically connected with the electric controller 10, and the electric controller 10 is used to set the speed and working mode, and the two sides of the working wheel 3 are respectively provided with a guide wheel 2 and a transition wheel 4, the guide wheel 2, the transition wheel 4 and the The diameters of the working wheels 3 are equal, and they are installed on the same straight line. The simulated traction sheave 1 with a surface hardness of HB200-260 is installed obliquely below the guide wheel 2, and a nylon material is installed obliquely below the transition wheel 4. The manufactured tension wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com