Weighing stirrer

The technology of agitator and weighing sensor is applied in the directions of mixer accessories, mixers with rotary stirring devices, chemical instruments and methods, etc., and can solve the problems of agitators without weighing devices, long working hours, unfavorable arrangements, etc. To achieve the effect of saving working time, improving work efficiency and reducing cumbersomeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

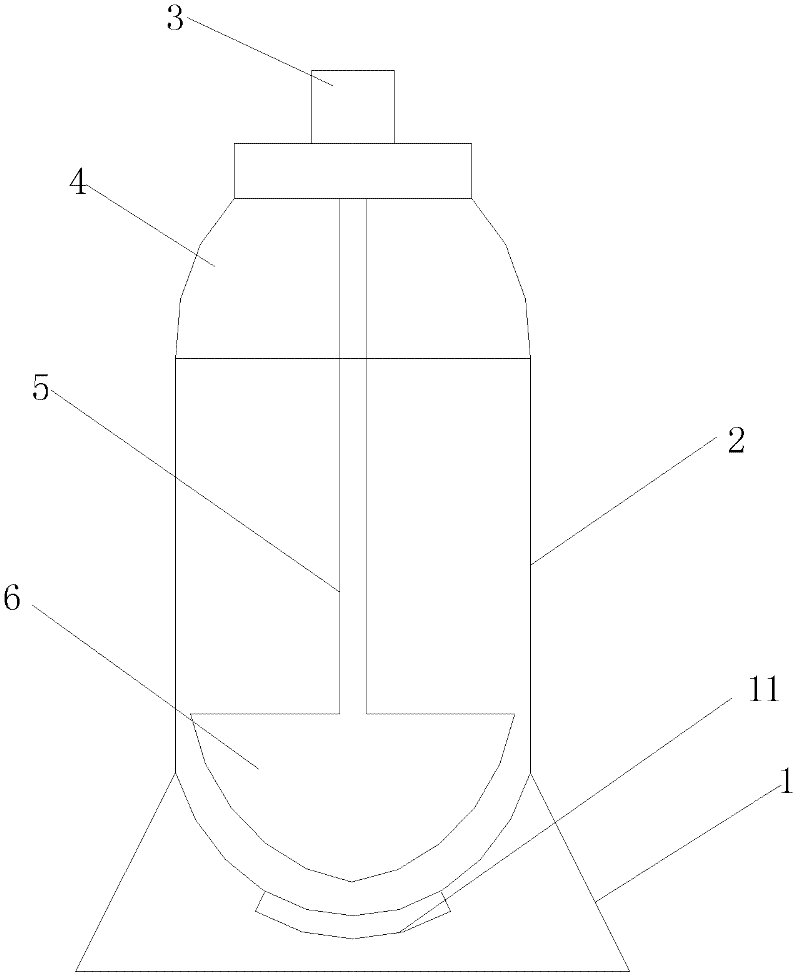

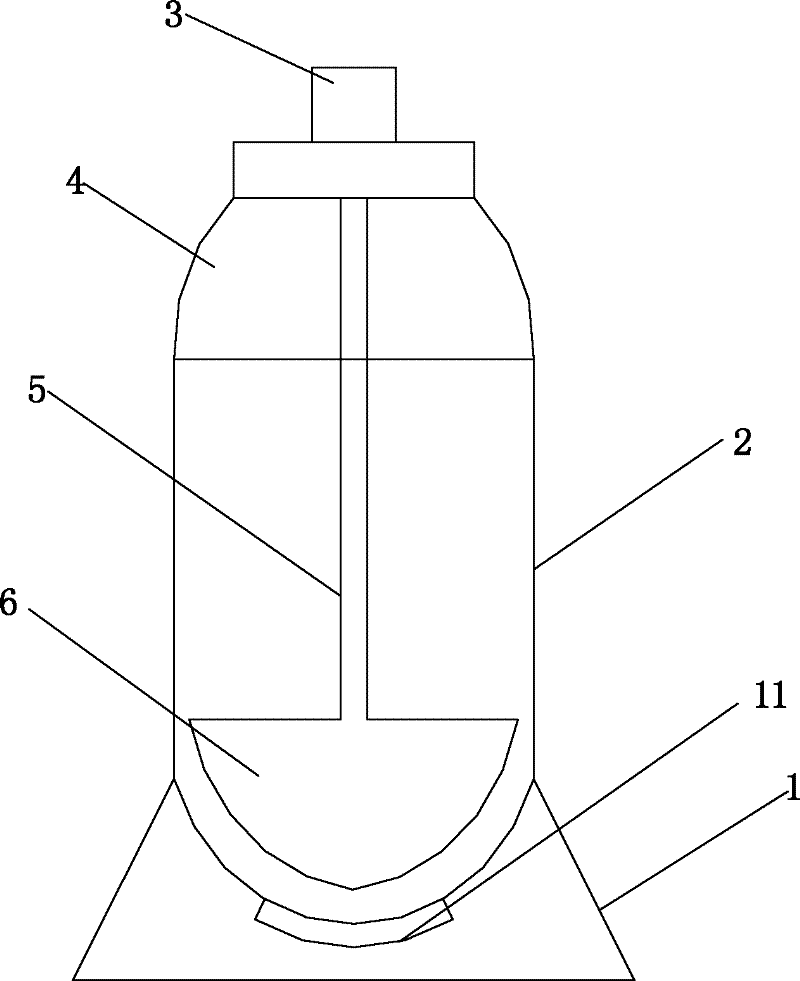

[0011] like figure 1 Described load cell, it comprises a stirring tank body 2, and the top of described stirring tank body 2 is provided with tank cover 4, and tank cover 4 is provided with drive motor 3, and the output end of drive motor 3 is connected with stirring shaft 5, the driving motor 3 drives the stirring shaft 5 to rotate, the end of the stirring shaft 5 is provided with a stirring paddle 6, the bottom of the stirring tank 2 is provided with a support 1, and the support 1 is provided with a pair of A weight sensor 11 for detecting the weight of the stirring tank body, the weight sensor can detect the quality of the raw materials added to the tank body.

[0012] The stirring paddle is a helical paddle, and the propeller blade is used to ensure the mixing effect of the agitator.

[0013] To sum up, the present invention can timely we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com