Method for refitting collapsible elements of recoiling machine

A coiler, expansion and contraction technology, which is applied in the field of coiler expansion and contraction parts for retrofitting Sendzimir mills, can solve the problems of equipment maintenance difficulty, processing difficulty, and the inability of the coiler to expand and shrink, so as to reduce the maintenance difficulty. and work intensity, reduce processing difficulty, and ensure the effect of supply quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

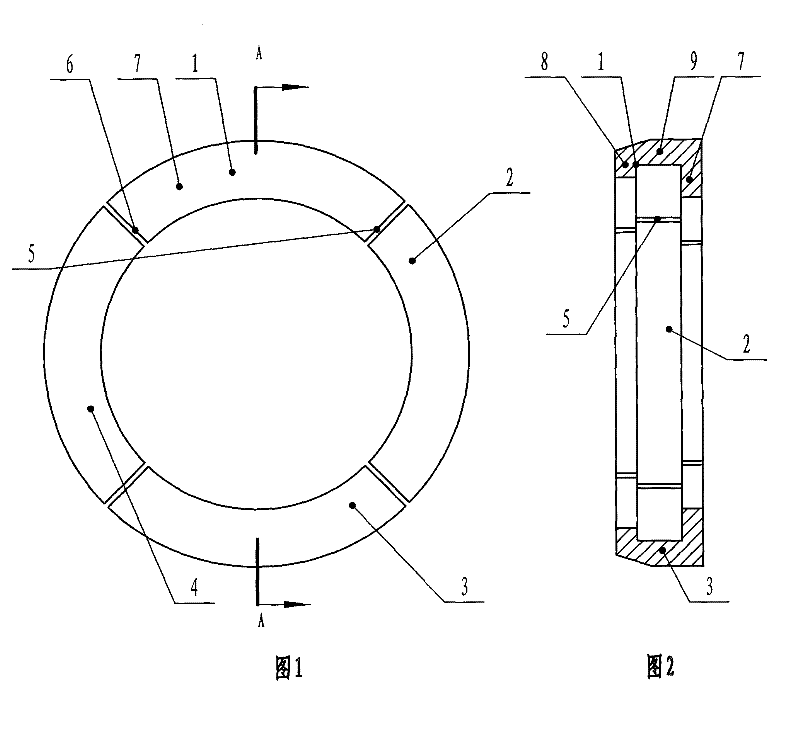

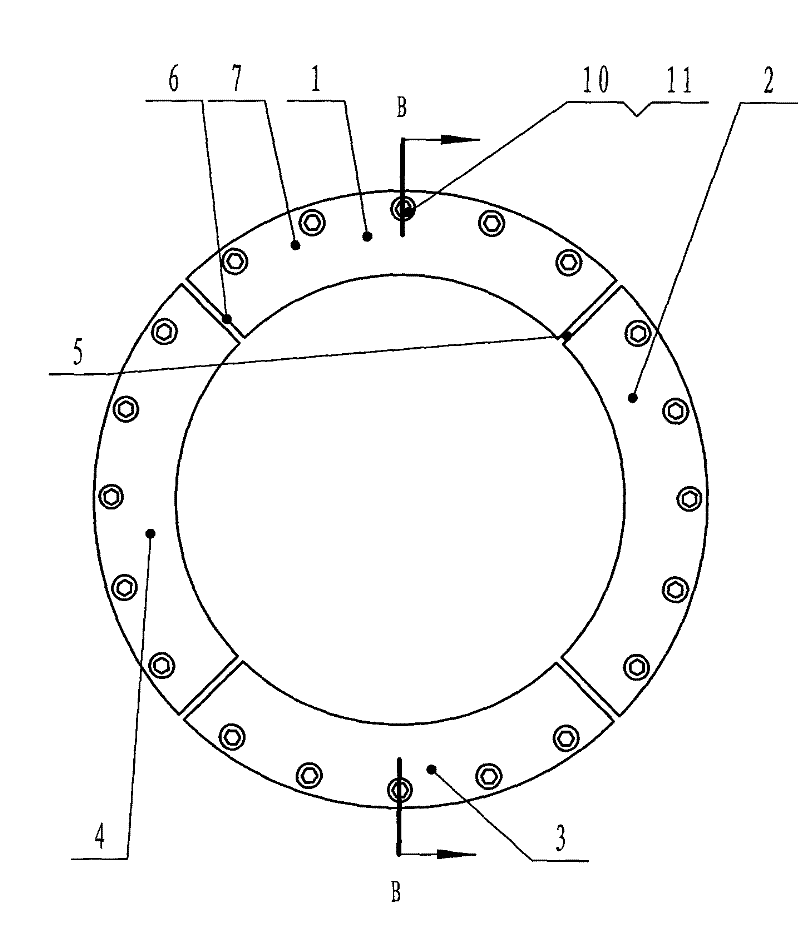

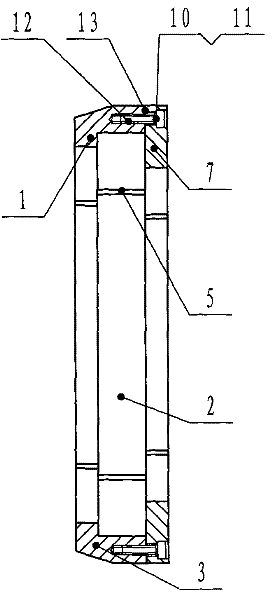

[0026] The original curved key plate of the coiler designed by Sendzimir see figure 1 and figure 2 . It is composed of arc-shaped key board assembly 1, arc-shaped key board assembly 2, arc-shaped key board assembly 3 and arc-shaped key board assembly 4. There is a gap between two adjacent arc-shaped key board assemblies. The gap 5 between the key board assembly 1 and the arc key board assembly 2 and the gap 6 between the arc key board assembly 4, each arc key board assembly such as the arc key board assembly 1 is composed of an annular ring assembly 9 and The annular plate assembly 7 and the annular plate assembly 8 at both ends are integrally formed. The inner diameter of the annular plate assembly 7 for installation is greater than the inner diameter of the annular plate assembly 8 , and the outer diameter of the annular plate assembly 7 for installation is equal to the outer diameter of the annular ring assembly 9 .

[0027] This embodiment includes the following steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com