Tapping machine special for evaporation pipe of adsorbing diffusion type refrigeration equipment

A technology of refrigeration equipment and evaporator tubes, which is applied in the field of tapping machines, can solve the problems of low efficiency and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

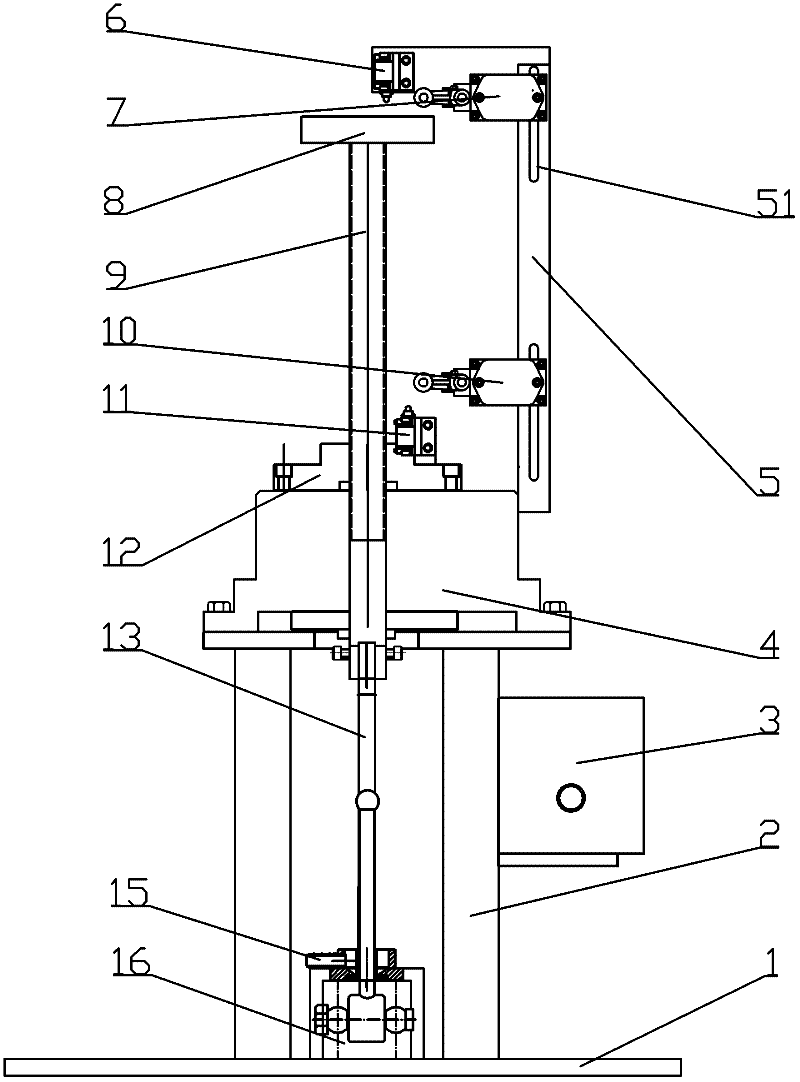

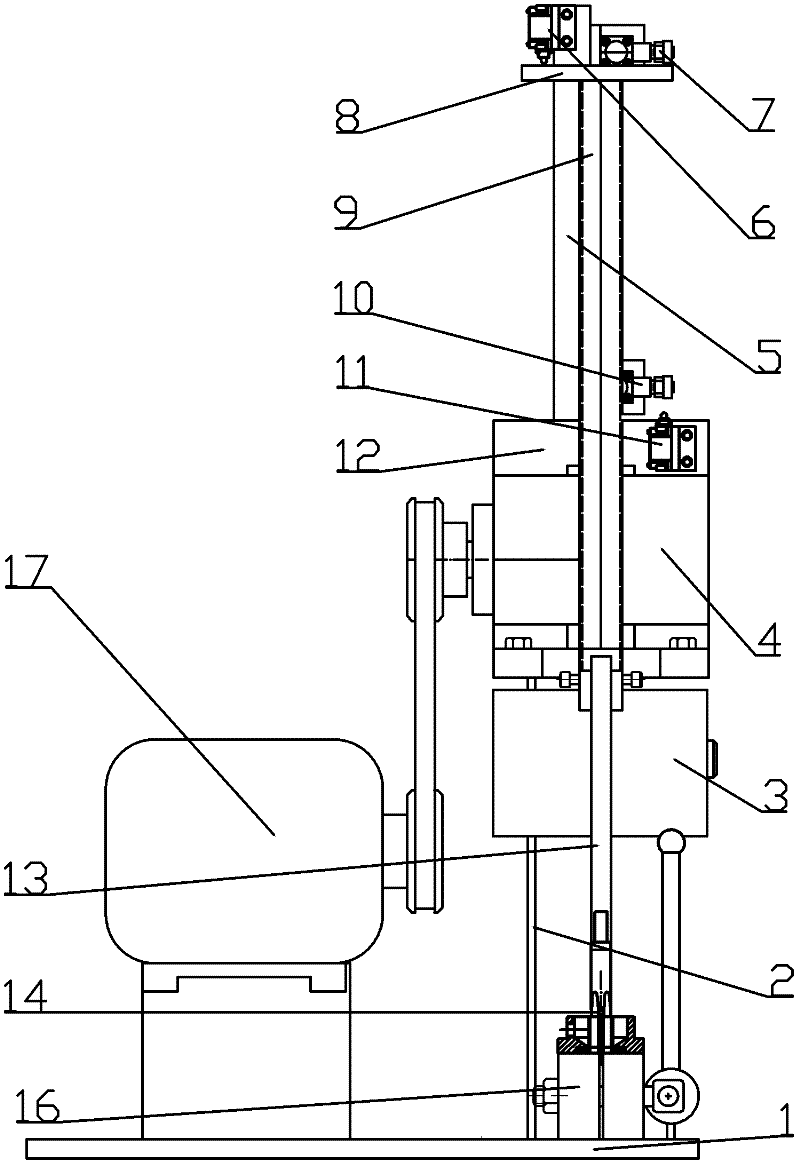

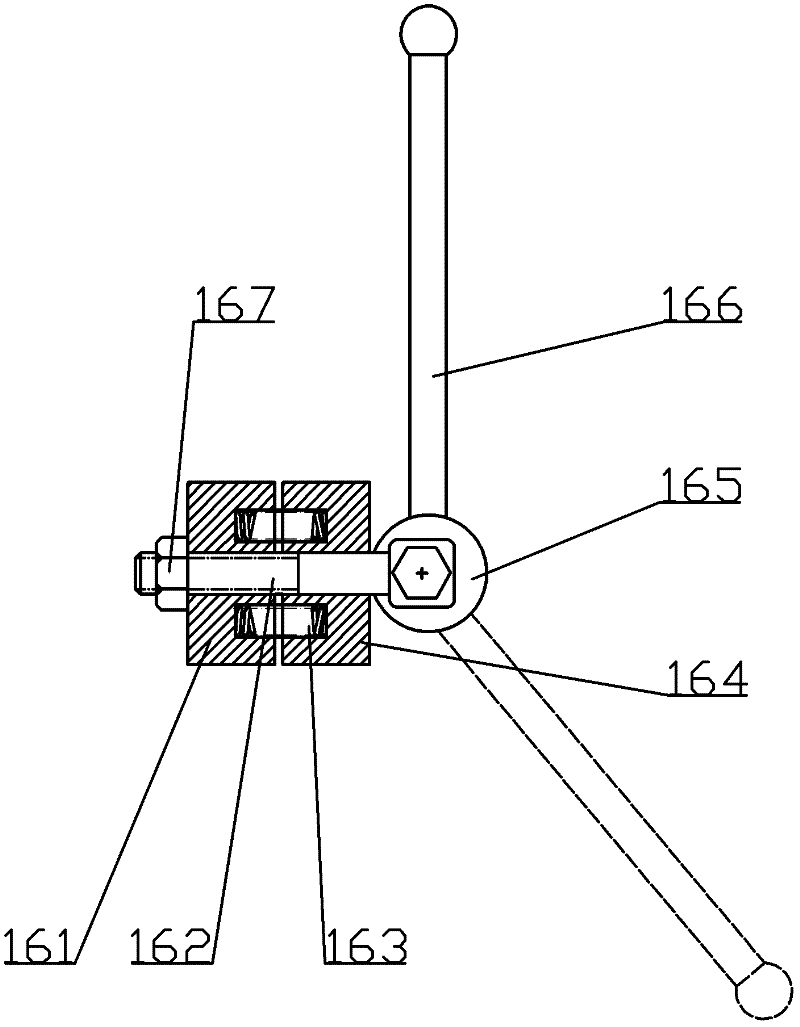

[0017] according to figure 1 , figure 2 and image 3 As shown, a special tapping machine for evaporating tubes of absorption-diffusion refrigeration equipment in this embodiment includes a base 1, a lower bracket 2, a control box 3, a motor 17, a traction screw 9 and a tap 14, and a clamping device 16; the lower end of the traction screw 9 is coaxially connected with a tap handle 13, the lower end of the tap handle 13 is connected with the tap 14, the lower bracket 2 and the motor 17 are fixed on the base 1, and the lower bracket 2 is provided with a Gear box 4, a traction nut 12 is arranged above the gear box 4, and the gear box 4 is connected with the motor 17 through a transmission member; the traction screw 9 is connected with the gear box 4 and the traction nut 12; above the lower bracket 2 Also be connected with upper bracket 5, upper bracket 5 bottoms are provided with reversing switch 10, and upper bracket 5 tops are provided with stop switch 7; 8; The motor 17, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap