Hydraulic compacting device

A compression device and oil pressure technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of long time required and slow movement speed, etc., and achieve easy control, shorten adjustment time, and fast compression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing;

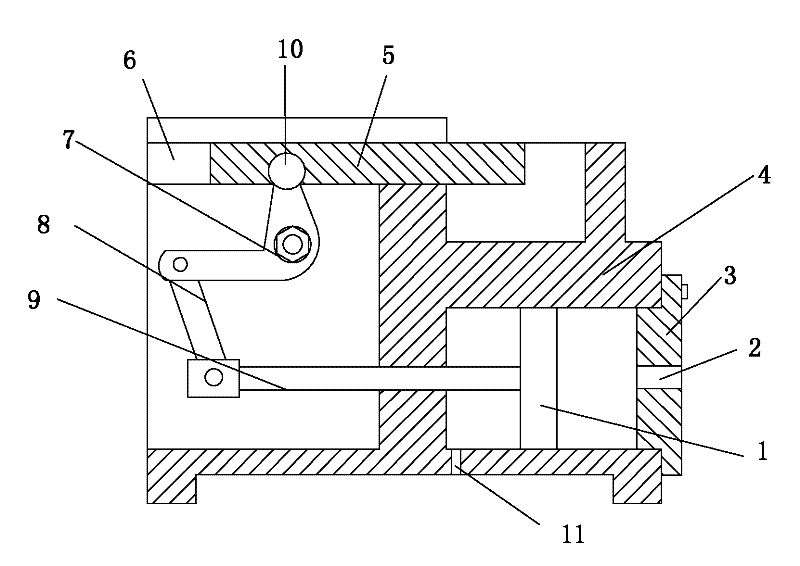

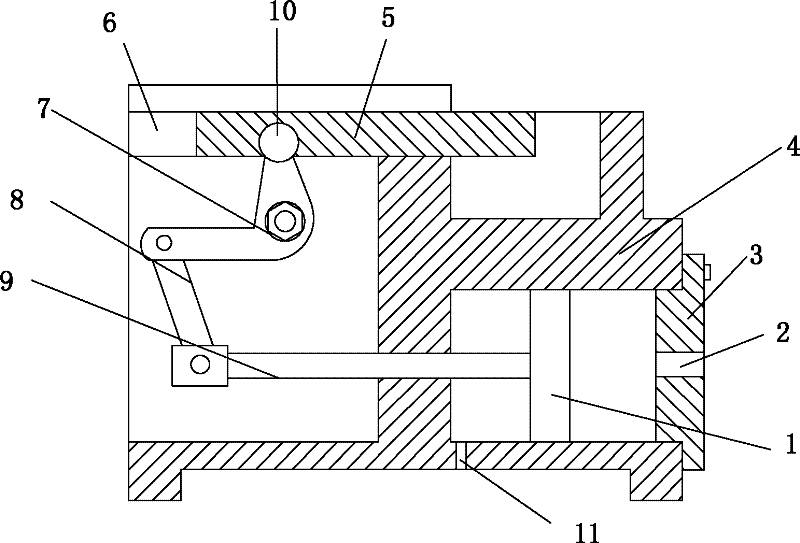

[0012] Such as figure 1 The hydraulic pressing device shown includes a base body, a hydraulic cavity is provided on the lower right side of the base body 4, and a cover plate 3 for sealing the hydraulic cavity, and the cover plate 3 is provided with a further Oil port 2, under the base body 4, there is an oil drain port 2 communicating with the hydraulic chamber. A piston 1 is arranged in the hydraulic chamber, and a piston rod 9 protruding from the hydraulic chamber is connected to the piston 1. The chute on the top of the base body 4 6. A sliding pressure plate 5 is arranged in the chute 6, and the piston rod 9 is connected with the pressure plate 5 through a linkage mechanism.

[0013] The linkage mechanism includes an L-shaped transmission rod 7 connected to the base body through a rotating shaft, one end of the L-shaped transmission rod 7 is connected to the slide pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com