Pre-compression machine for crushing municipal domestic waste

A technology of municipal solid waste and pre-compressor, which is applied in the direction of presses, presses, and manufacturing tools using rotating pressure components, which can solve the problems of high-frequency crushing, continuous feeding of crushers, and safety production hidden dangers, etc. problem, to prevent the stuck material from stalling, have a long service life, and meet the effects of high-frequency crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

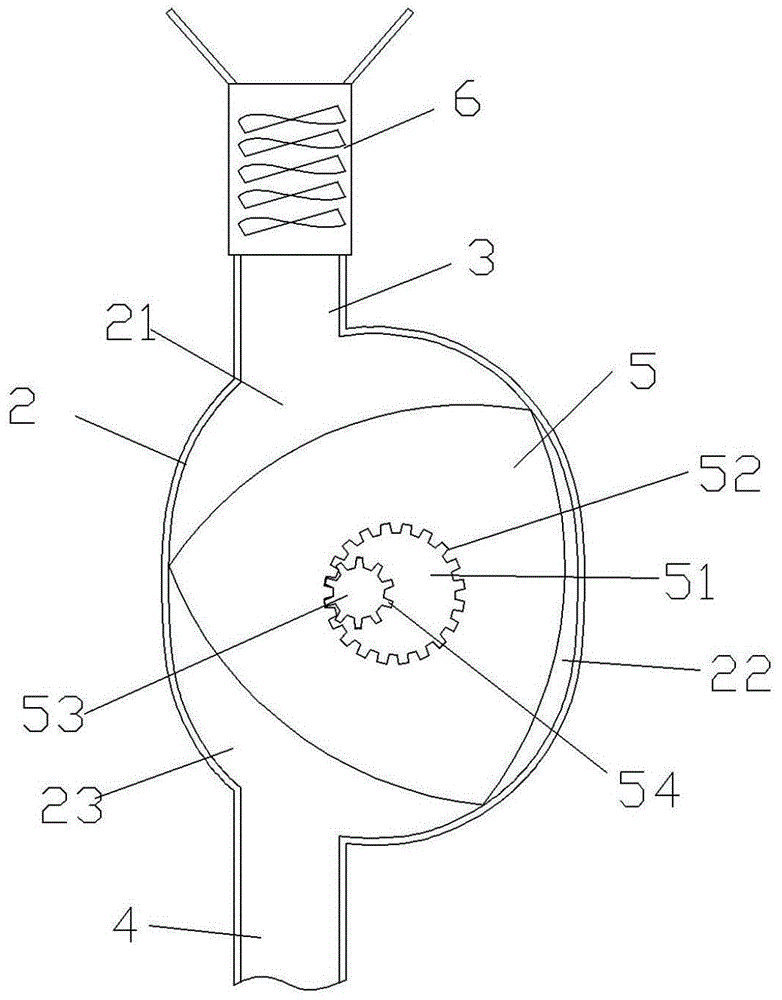

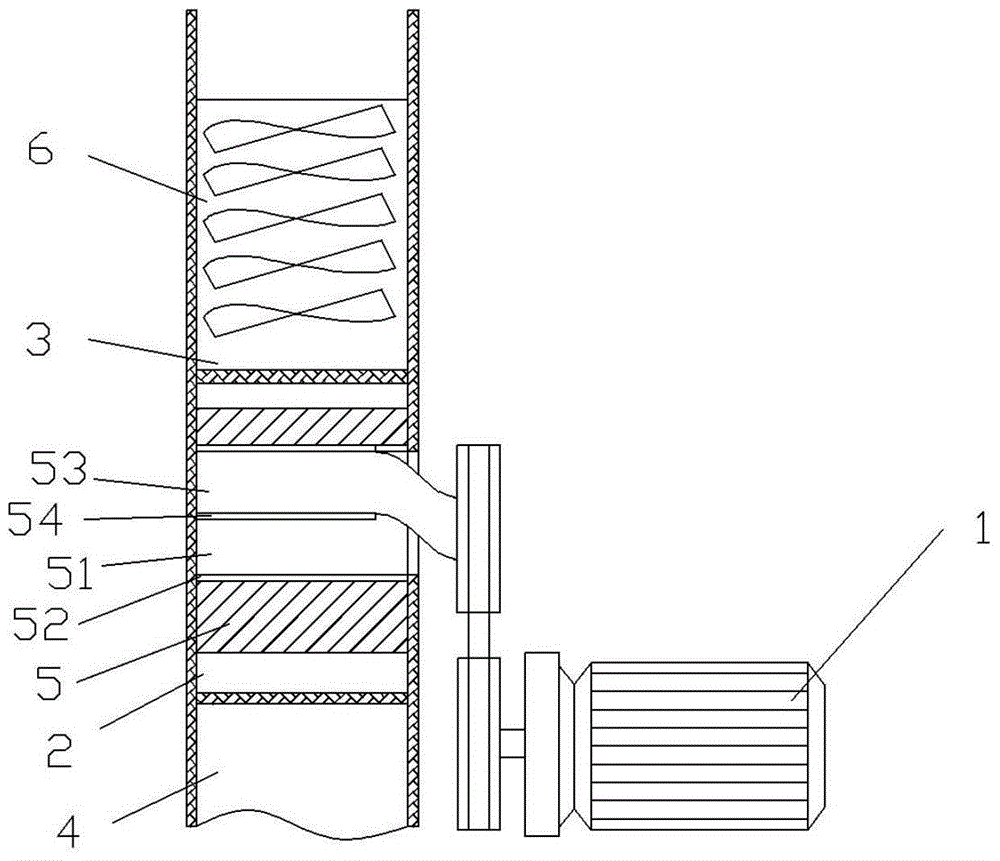

[0020] A pre-compressor for municipal solid waste crushing, comprising a feed port 3, a compression chamber 2, a discharge port 4 and a motor 1, the compression chamber 2 is arranged between the feed port 3 and the discharge port 4, and its characteristics In that: a compression rotor 5 is arranged in the compression chamber 2, the compression rotor 5 is a Leroux triangular rotor, the compression chamber 2 is cocoon-shaped, a rotor hole 51 is arranged in the center of the compression rotor 5, and a rotor gear 52 is arranged on the inner wall of the rotor hole 51, and in the rotor hole Rotor shaft 53 is also provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com