Two-electrolyte direct carbon fuel cell and assembling method thereof

A dual-electrolyte and fuel cell technology, which is applied in the direction of solid electrolyte fuel cells, molten electrolyte fuel cells, fuel cells, etc., can solve problems such as difficulty in achieving continuous operation and power generation of batteries, limitation of active area of electrodes, and difficulty in improving battery performance. , to achieve the effect of reducing ohmic loss, accelerating electrode reaction and increasing effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

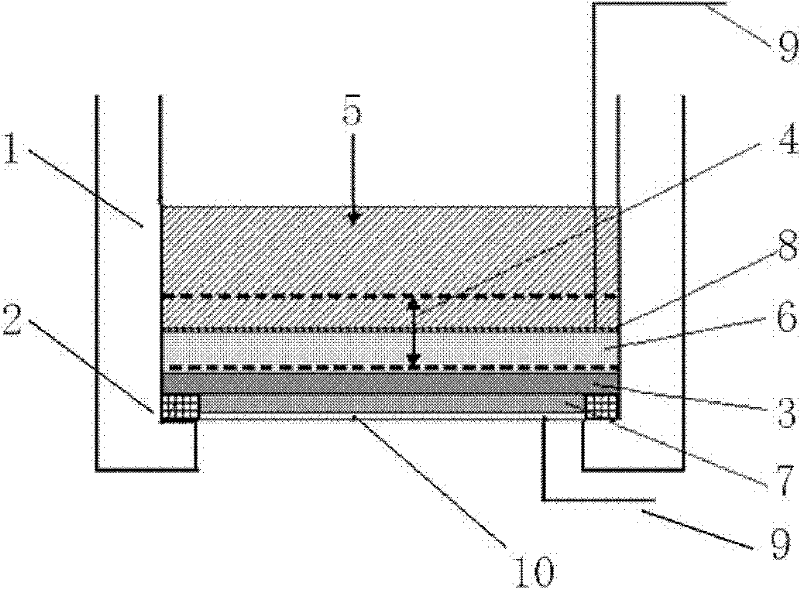

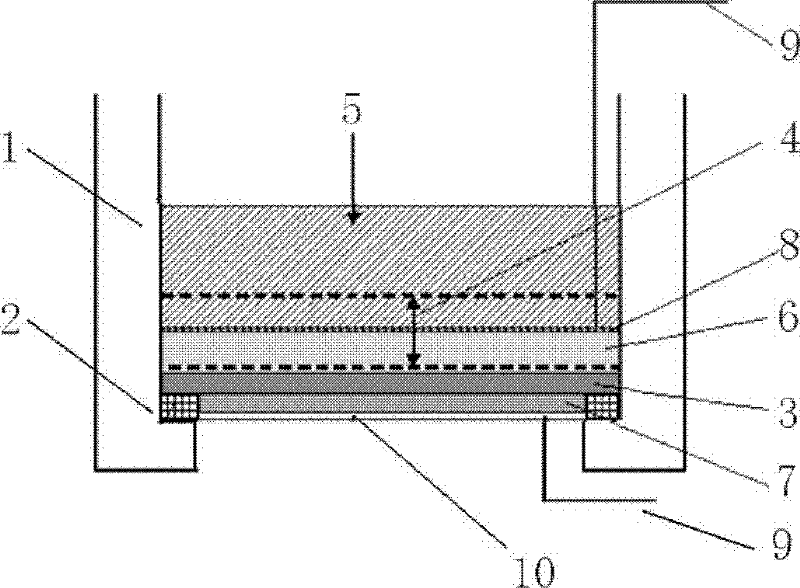

[0027] Such as figure 1 As shown, this embodiment includes: an anode part 1, a cathode part 2 and a carbonate layer 3 and a solid oxide layer 4 as a double electrolyte therebetween, and the anode part includes: a carbon substrate layer 5 and a porous anode plate 6, the cathode part is a porous cathode plate 7, the solid oxide layer 4 is located between the porous anode plate 6 and the porous cathode plate 7, and the carbonate layer 3 is located between the solid oxide layer 4 and the porous anode plate 6 .

[0028] The carbonate layer 3 refers to: Li with a molar ratio of 62:38 2 CO 3 with K 2 CO 3 mixture. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com