Reinforced Concrete Continuous Rigid Frame Bridge Compositely Reinforced by Tension Surface and Its Construction Method

A reinforced concrete, layer composite technology, applied in bridges, bridge parts, bridge construction and other directions, can solve problems such as accidental deformation of bridges, hidden dangers of bridge durability problems, differences in stress distribution, etc., to increase load capacity and ductility. Improve safety and durability, improve the effect of cracking bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

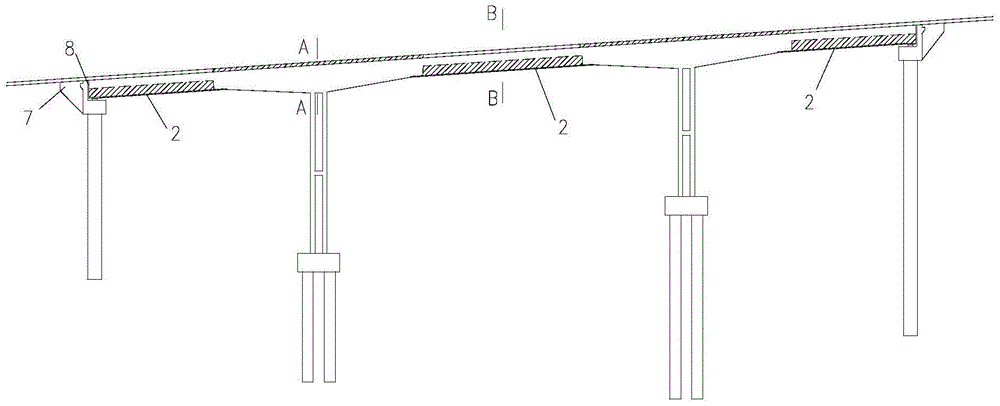

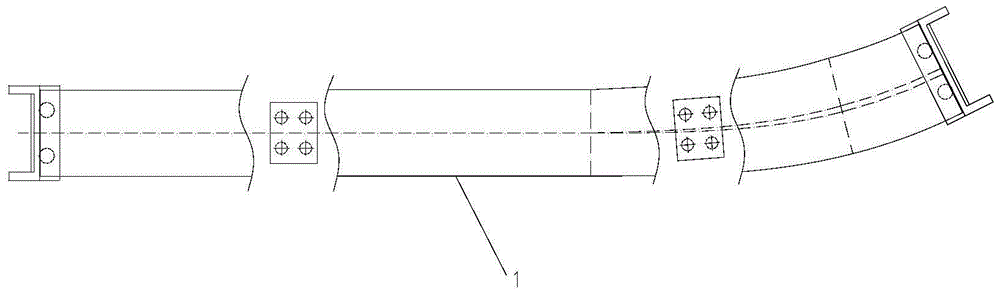

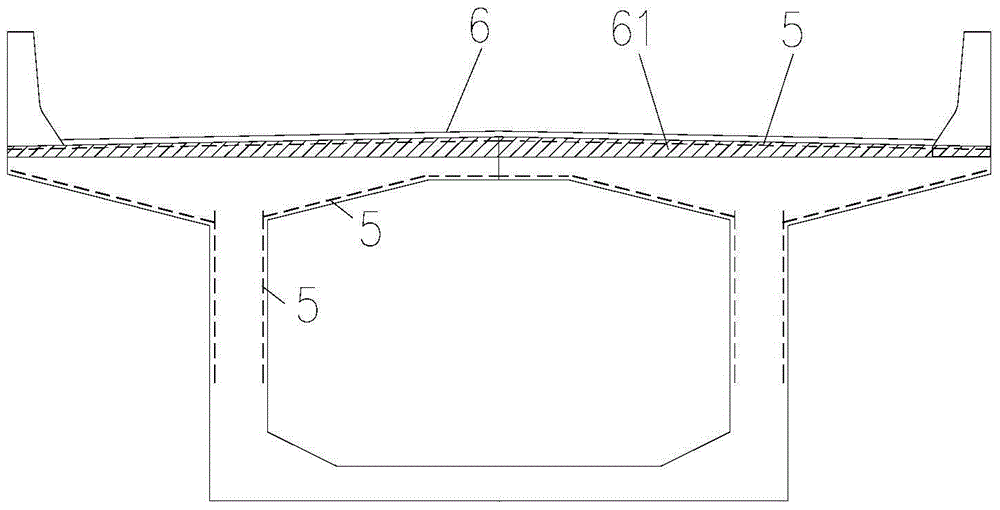

[0030] As shown in the figure: the reinforced concrete continuous rigid frame bridge reinforced by the tension surface layer of the present embodiment includes pier, abutment 7, reinforced concrete girder 1 and bridge deck 6, and the pier top of the main girder 1 is negatively bent The moment section is a box-shaped beam structure, the positive moment section of the main beam 1 is a Π-shaped section beam structure, and the bottom surface of the beam rib of the positive moment section is provided with a steel plate reinforcement layer 2 fixedly connected to the stirrup 11 and the main girder 1 is poured from composite concrete evenly mixed with flexible fibers; the steel plate reinforcement layer 2 is connected to the bottom edge of each stirrup 11 by welding; the steel plate reinforcement layer 2 may include a steel plate body and a longitudinally fixed On the rib plate on the steel plate body, the rib plate is provided with connecting holes for the hoops 11 to pass through. Af...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is only the composition of the filler material for the expansion joint 8. In this embodiment, the filler material in the expansion joint 8 includes 22 parts by weight of red mud, 8 parts of neoprene, 15 parts Polymethyl methacrylate, 5 parts sodium lauryl sulfate, 6 parts hydroxypropyl methylcellulose, 4 parts FERRO fiber, 7 parts steel fiber, 6 parts n-butanol, 5 parts monoalkoxy pyrophosphate ester, 3 parts of methyl tributyl ketoxime silane, 3 parts of trimethylolpropane and 1.5 parts of diisooctyl phthalate; after testing, the 28d compressive strength of the filler material of this composition is 86MPa, and the 28d flexural strength The strength is 8MPa, meeting the requirements of C55 / 65.

Embodiment 3

[0045] The difference between this embodiment and Embodiments 1 and 2 is only the composition of the filler material for the expansion joint 8. In this embodiment, the filler material in the expansion joint 8 includes 25 parts by weight of red mud, 10 parts of neoprene, 20 parts of polymethyl methacrylate, 8 parts of sodium lauryl sulfate, 8 parts of hydroxypropyl methylcellulose, 6 parts of FERRO fiber, 10 parts of steel fiber, 9 parts of n-butanol, 7 parts of monoalkoxy Pyrophosphate, 4 parts of methyl tributylketoxime silane, 4 parts of trimethylolpropane and 3 parts of diisooctyl phthalate; after testing, the compressive strength of the filler material of this composition is 82MPa at 28d, and the compressive strength at 28d The flexural strength is 7MPa, meeting the requirements of C55 / 65.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com