Metal joint assembly device with metal screw cap at end of rubber pipe for vechile

A metal joint and metal technology, applied in the direction of hand-held tools, manufacturing tools, etc., to improve labor efficiency, prevent the output of unqualified products, and ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

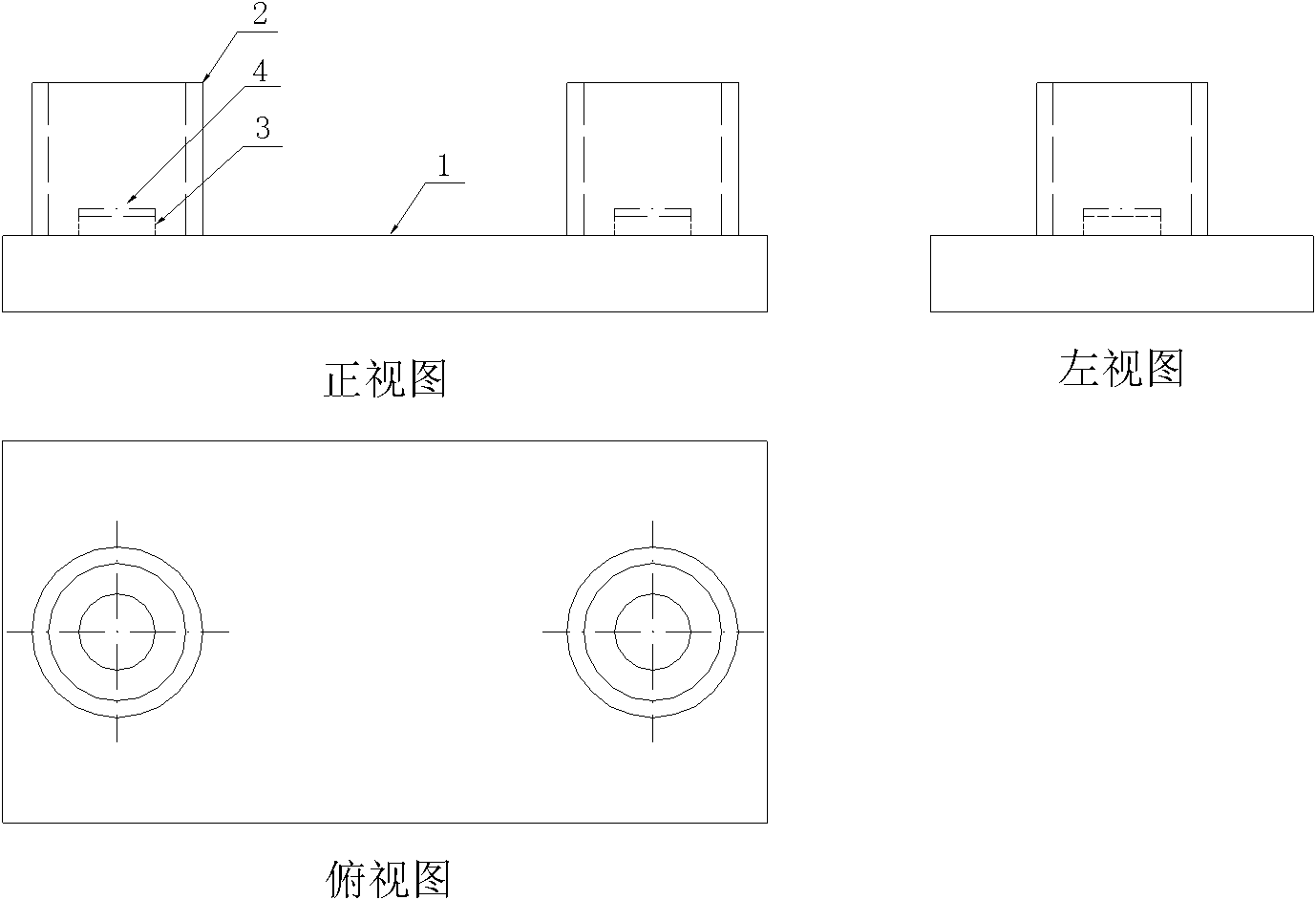

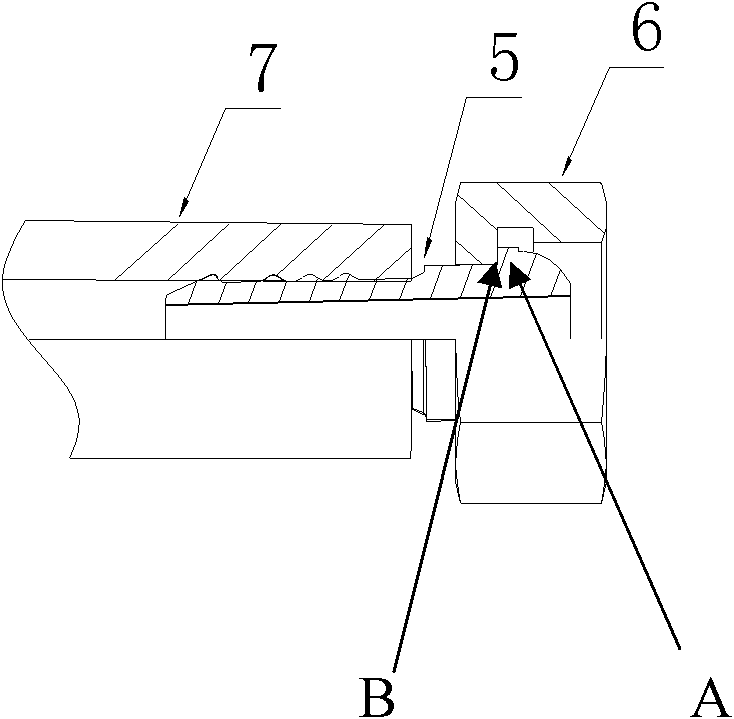

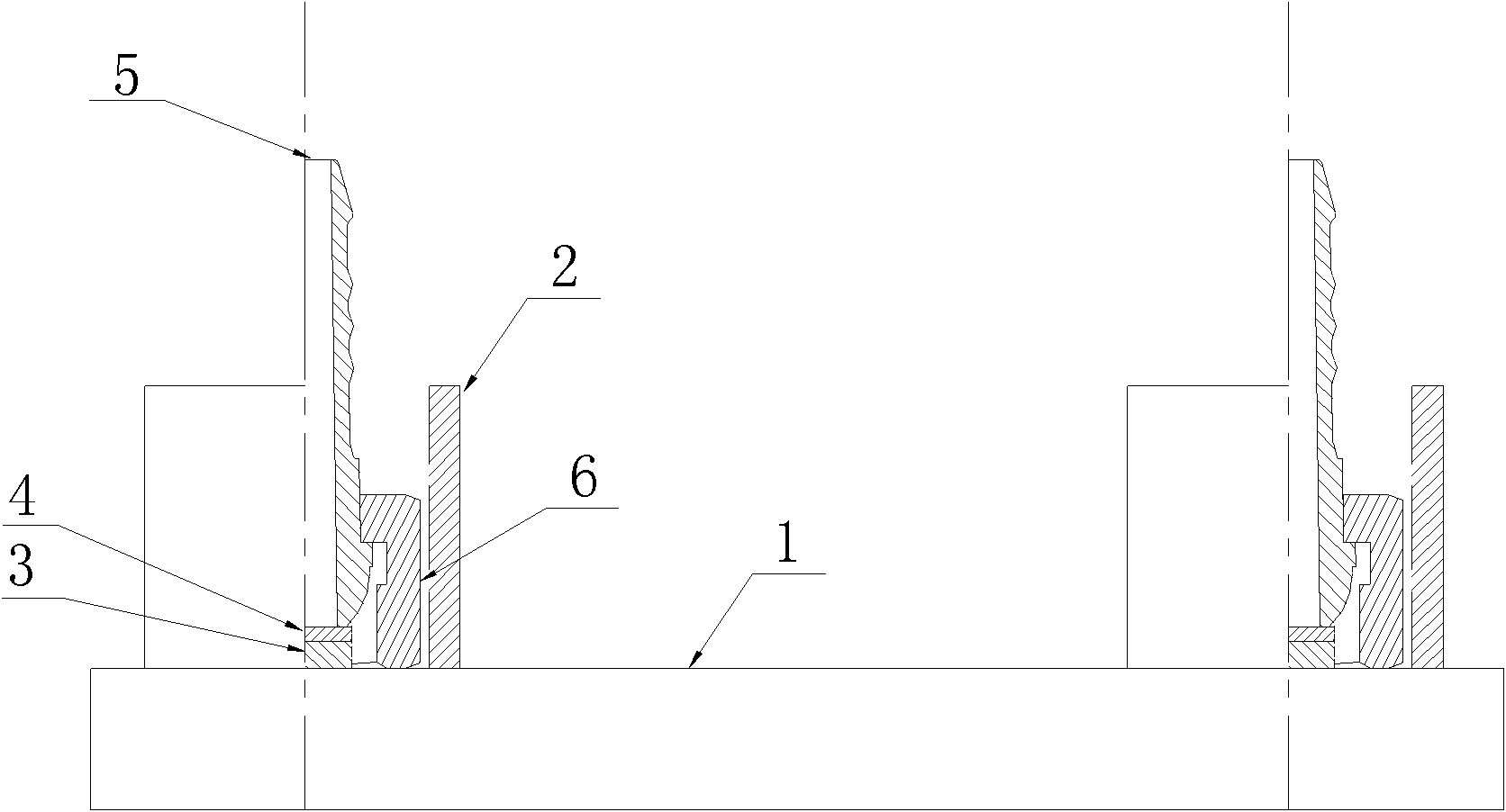

[0014] The specific embodiments of the present invention will be described below with reference to the figures.

[0015] A metal joint assembly device with a metal nut is used to assemble the end of the automobile rubber hose. The base 1 is a rectangular parallelepiped made of resin. It mainly plays the role of fixing the annular sleeve 2 and the positioning member 3. The material, due to its low density and high hardness, has a small mass, is easy to move, and is not easily damaged.

[0016] The annular sleeve 2 is made of stainless steel, the inner diameter is slightly larger than the diagonal length of the metal nut 6, and the height is about twice that of the metal nut 6 and half of the metal joint 5, which is convenient for the metal joint 5 and the metal screw. The cap 6 is put in smoothly; the surface is smooth to prevent scratches and bruises when the metal nut 6 and the metal joint 5 are put in, such as image 3 ; It is bonded to base 1 with high-strength glue.

[0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap