Adhesive bound double book make-up and cutting method

A duplex and cutting technology, which is applied in metal processing and other directions, can solve the problems of paper waste and large cutting margin, etc., and achieve the effects of reducing cutting scraps, precise cutting parts, and saving paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Books with a finished size of 128mm×182mm or less must be typesetting in duplex. There is a trimming margin between the connecting sides of the two editions. The trimming margin is 2~4mm, and there are finished trimming lines on the layout;

[0014] The arranged version is printed on 560mm×787mm paper, and after printing, it is bound in glue.

[0015] In the middle part of the cutting margin position of the semi-finished duplex imposition, use a duplex imposition spine cutting machine to cut a gap, the size of the gap: width 3mm, depth 2mm;

[0016] Cut along the finished cut line of the adjacent edge of one of the individual copies;

[0017] Then cut along the finished cutting line of the connected edge of the other single.

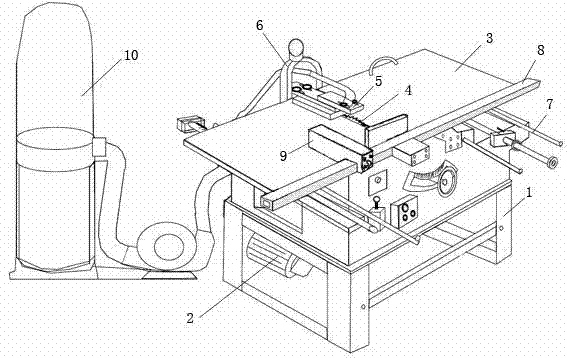

[0018] The special sawing device used is a glue-bound double-page imposition book spine cutting machine. The specific structure is described in detail with reference to the attached drawings:

[0019] Such as figure 1 As shown, the glue-bound d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com