Multi-level lifting type tail plate device of logistic automobile

A lifting and tailgate technology, which is applied to vehicles with elevated loading platforms, etc., can solve the problems of limited application scope, poor flexibility, and laboriousness, and achieve the effects of expanding the lifting range, smooth movement, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

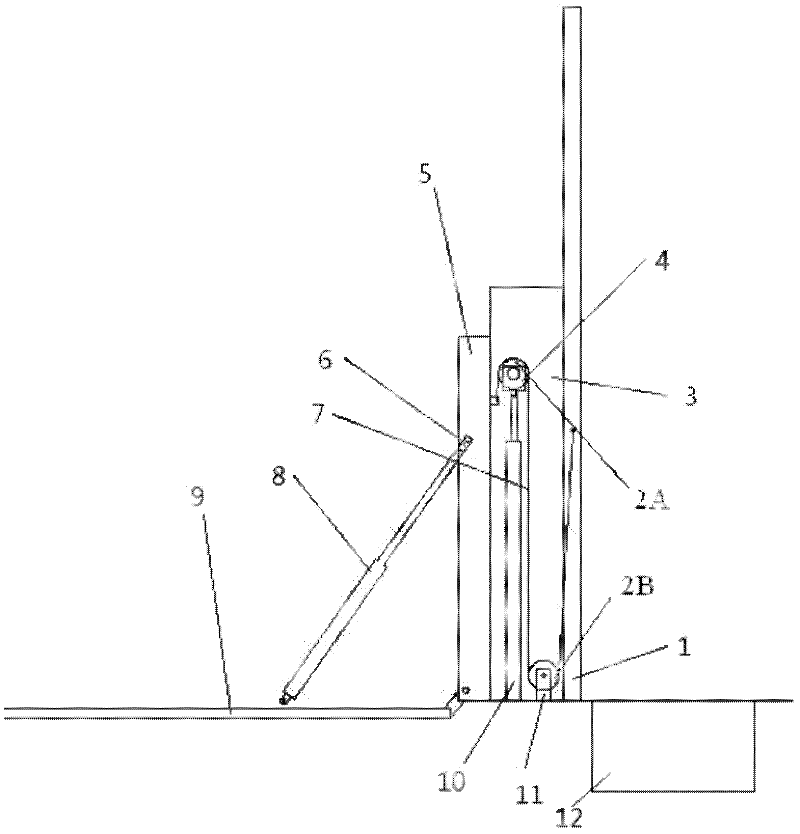

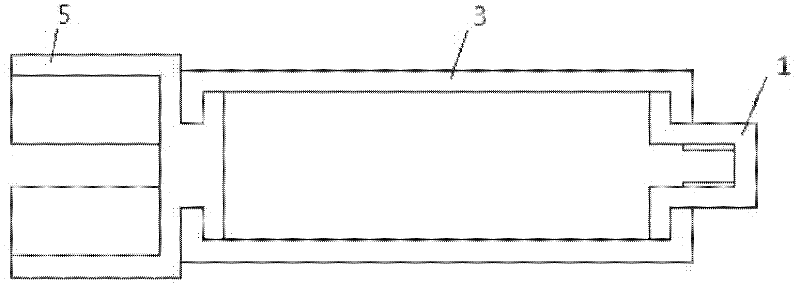

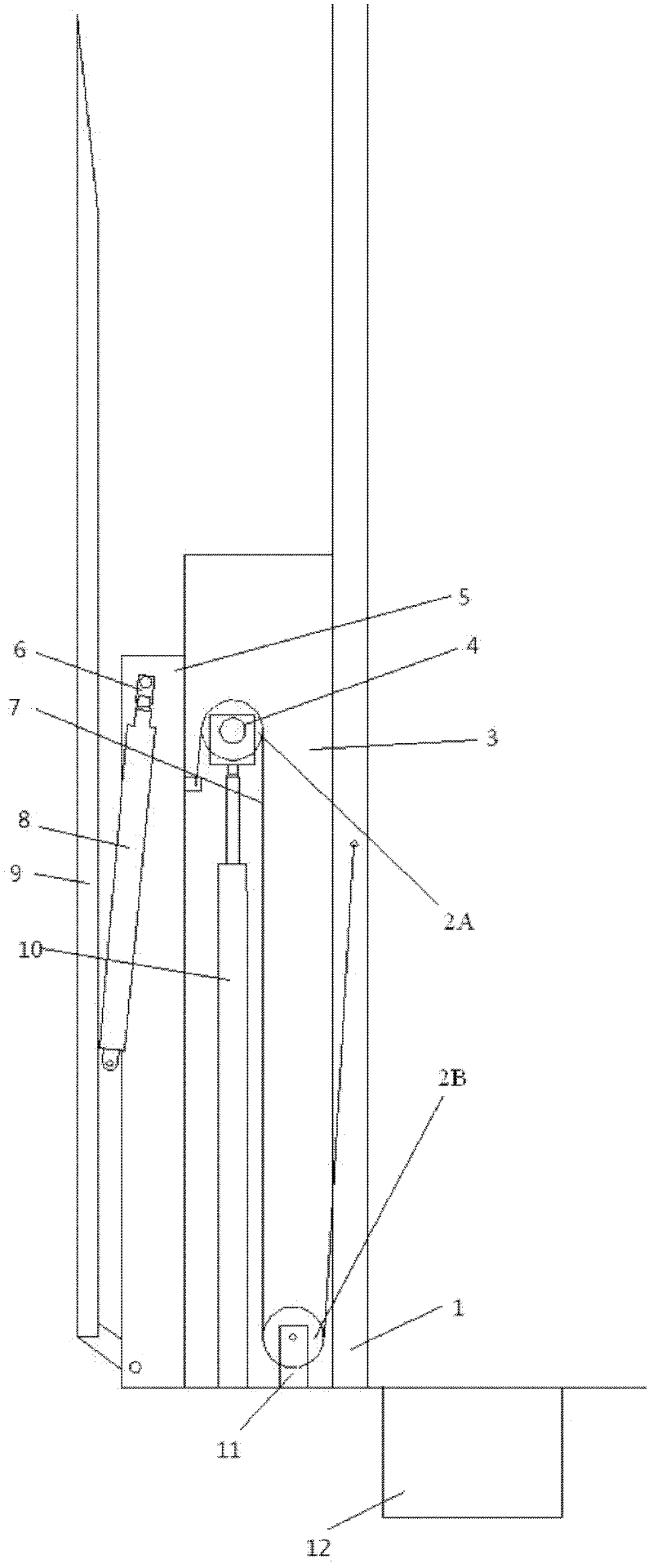

[0023] Such as figure 1 As shown, the multi-stage lifting tail lift device for logistics vehicles in a preferred embodiment of the present invention includes a tail lift 9 and two sets of tail lift drive devices respectively arranged on both sides of the tail lift. The bottom of the tail lift 9 is hinged on the secondary slide At the bottom of the block 5, when the tail plate 9 is laid flat, the bottom surface of the tail plate 9 is flush with the bottom plate of the carriage; each set of tail plate driving devices includes: guide rail 1, first-level slider 3, second-level slider 5, lifting drive device and telescopic traction rod , the guide rail 1 is arranged on the side railing of the automobile compartment, and the length of the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com