Control and display method and device of working state of weft detector of spinner

A technology for controlling display and working status, applied in textiles, looms, textiles and papermaking, etc., can solve the problems of affecting the working efficiency of textile machines, fabric quality, difficulty in mastering the adjustment method, and spinning machine idle stop, etc., to achieve intuitive display and adjustment. Easy, controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Figure 5 Is the control principle block diagram of the present invention. The weft detection control unit is composed of FT detection isolation circuit, phase shift adjustment circuit, width adjustment circuit, weft signal detection and processing circuit, weft detection processing circuit, FT' isolation output circuit, F isolation output circuit, display circuit and display.

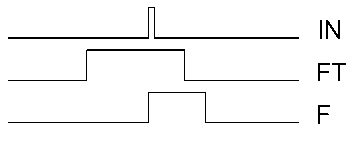

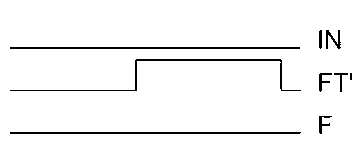

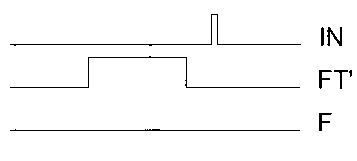

[0042] When the textile machine is running, it drives the stop iron 1 to rotate. Within a certain angle range (determined by the arc length of the stop iron, usually 30°), the stop iron blocks the proximity switch 2, so that the proximity switch outputs a timing signal FT with a certain width. The weft detection processing circuit processes the FT signal, the displacement signal generated by the phase shift adjustment circuit and the width signal generated by the width adjustment circuit to form the FT' signal. To the main controller as a timing signal for shutdown logic judgment. When the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com