Method for chiseling away cast-in-place pile head concrete rapidly

A technology of cast-in-situ piles and concrete, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve time-consuming and labor-intensive problems, and achieve the effects of avoiding quality accidents, improving construction efficiency, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

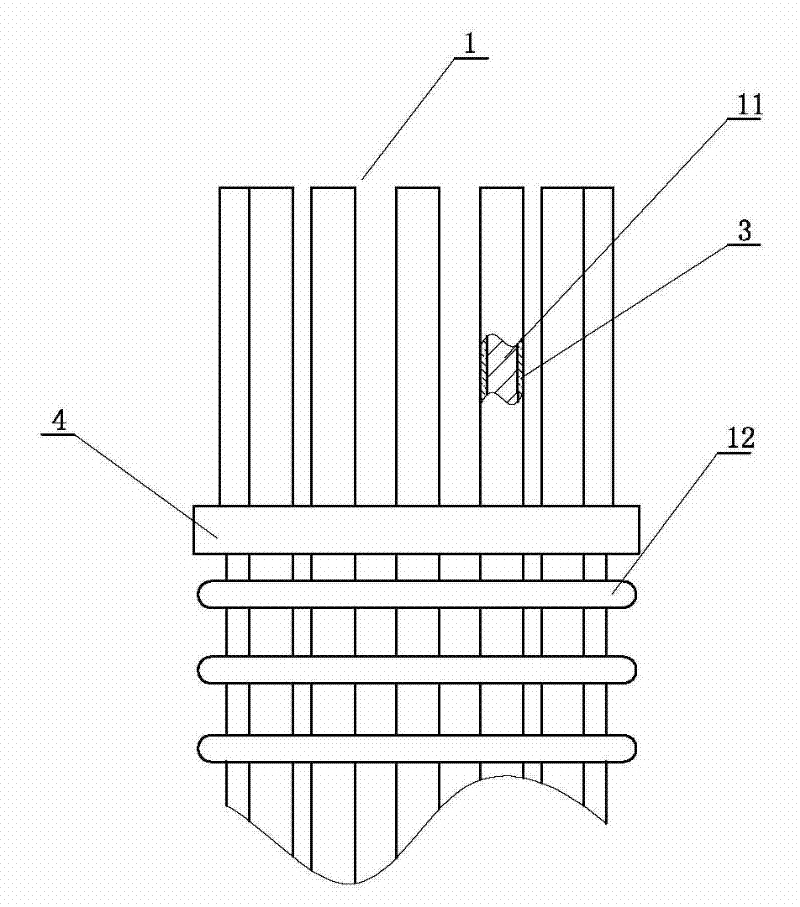

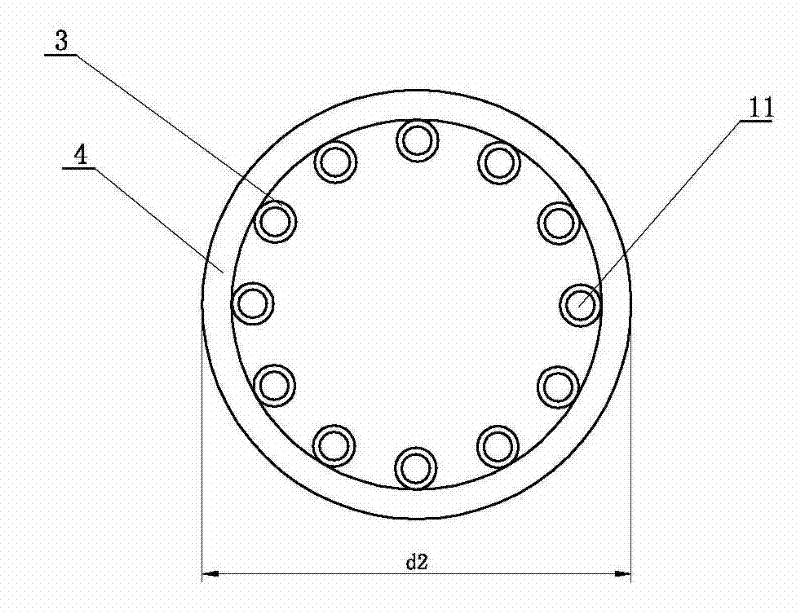

[0034] see Figure 1-7 A method for quick removal of cast-in-place pile pile head concrete, including measuring the cast-in-place pile hole and processing the cast-in-situ pile reinforcement skeleton, the operating steps of the method are:

[0035] A. Process the cast-in-place pile reinforcement skeleton 1 according to the measured cast-in-place pile hole length and diameter; the cast-in-place pile reinforcement skeleton is made up of a pile head and a pile base, and The dividing line is the designed pre-separation position 5, the position above the pre-separation position is the pile head, and the position below the pre-separation position is the pile base; the pile base of the cast-in-place pile reinforcement skeleton includes the lower part of the vertical reinforcement 11 And hoop reinforcement 12, the pile head of described cast-in-situ pile reinforcement skeleton comprises the top of vertical reinforcement 11, the vertical reinforcement of the pile head of described cast...

Embodiment 2

[0047] This embodiment is an improvement made on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be used as this embodiment. The content of the example will not be repeated here.

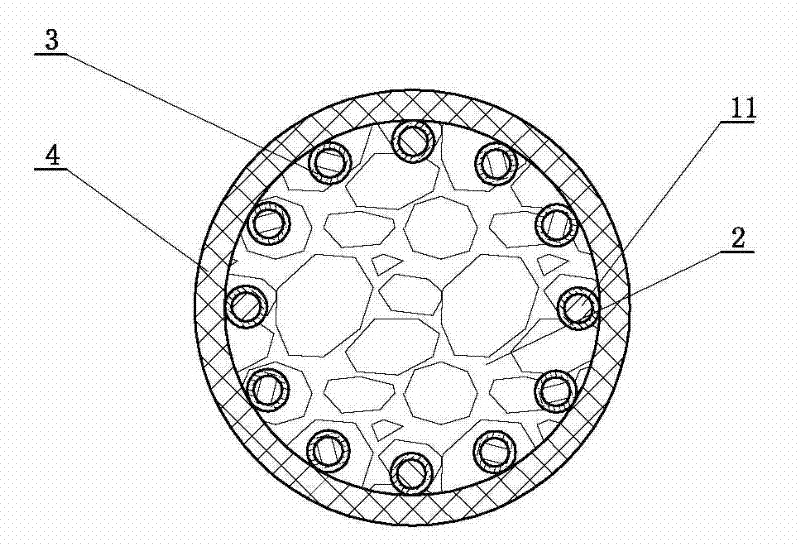

[0048] The upper end of the separation sleeve is flush with the top of the vertical reinforcement at the pile head, and the lower end of the separation sleeve is on the same plane as the lower end of the separation collar. see image 3 , the upper end of the separation sleeve is flush with the top of the vertical steel bar at the pile head, the lower end of the separation sleeve is on the same plane as the lower end of the separation collar, and the lower end of the separation collar is preferably in line with the pre-separation collar. The position is flush. This can better prevent the poured concrete from adhering to the steel skeleton at...

Embodiment 3

[0050] This embodiment is an improvement made on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be used as this embodiment. The content of the example will not be repeated here.

[0051] see Figure 8 , one end of the separation sleeve is provided with a head.

[0052] The separation sleeve can be used to wrap the vertical steel bar with insulating material, or a sleeve-type separation sleeve can be used. The separation sleeve used in this embodiment is a circular tube-shaped sleeve, and the separation sleeve is directly placed on the vertical steel bar. Preferably, one section of the separation sleeve is provided with a head, and the end with the head is the upper end. , installed on the top of the vertical reinforcement at the head of the pile, and the upper end is closed to prevent concrete from seeping into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com