Hydrofracture bottom-hole pressure monitoring process

A bottomhole pressure and monitoring process technology, which is applied in the field of development and oil and gas field exploration, can solve the problems of large differences in physical properties at buried depth, failure to consider wellbore friction resistance, working fluid viscosity, and inaccurate reservoir evaluation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

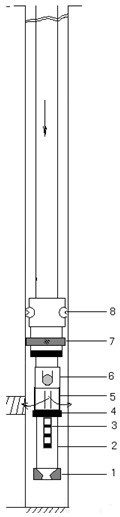

[0020] The hydraulic fracturing bottomhole pressure monitoring process includes the following steps: 1) The pressure monitoring device carrying the high-precision electronic pressure gauge 3 is lowered into the vicinity of the fracturing bottomhole measure layer while drilling; 2) The high-precision electronic pressure gauge 3 monitors the entire fracturing The bottom hole pressure and temperature changes are monitored throughout the process; 3) After the fracturing is completed, the pressure monitoring device is pulled out while drilling or pulled out through steel wire operation.

Embodiment 2

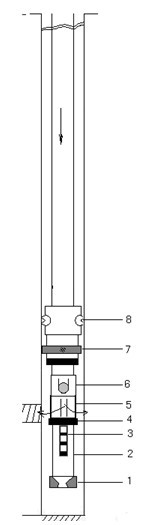

[0022] The hydraulic fracturing bottomhole pressure monitoring process includes the following steps: 1) The pressure monitoring device carrying the high-precision electronic pressure gauge 3 is lowered into the vicinity of the fracturing bottomhole measure layer while drilling; 2) The high-precision electronic pressure gauge 3 monitors the entire fracturing The bottom hole pressure and temperature changes are monitored throughout the process; 3) After the fracturing is completed, the pressure monitoring device is pulled out while drilling or pulled out through steel wire operation. Such as figure 1 As shown, when the fracturing monitoring device is used for oil well single-layer fracturing operations, it consists of a throttle nozzle I1, a pressure gauge support cylinder 2, a double male dead plug 4, a slotted pipe 5, and a throttle nozzle II6. , a packer 7, and a hydraulic anchor 8 are sequentially connected in series from bottom to top, and a high-precision electronic press...

Embodiment 3

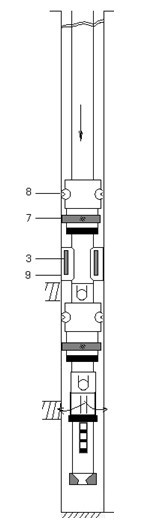

[0024] The hydraulic fracturing bottomhole pressure monitoring process includes the following steps: 1) The pressure monitoring device carrying the high-precision electronic pressure gauge 3 is lowered into the vicinity of the fracturing bottomhole measure layer while drilling; 2) The high-precision electronic pressure gauge 3 monitors the entire fracturing The bottom hole pressure and temperature changes are monitored throughout the process; 3) After the fracturing is completed, the pressure monitoring device is pulled out while drilling or pulled out through steel wire operation. Such as figure 2 As shown, when the above-mentioned fracturing monitoring device is used for the two-layer fracturing operation of the static string, it is composed of a throttle nozzle I1, a pressure gauge support cylinder 2, a double male dead plug 4, and a slotted pipe 5. , throttle nozzle II 6, tubing 10, eccentric pressure gauge holder 9, packer 7, and hydraulic anchor 8 are sequentially conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com