Method for measuring mixing uniformity of tobacco shreds of cigarettes

A technology of mixing uniformity and measurement method, which is applied in the field of tobacco processing, can solve the problem that the detection method cannot truly reflect the uniformity of the cigarette processing process, and achieve the effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

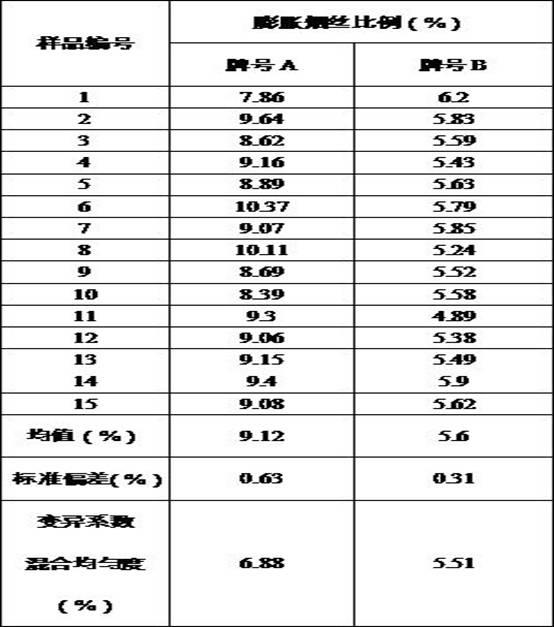

[0024] Taking two brands of cigarettes A and B of an enterprise as an example, measure the blending uniformity of cut tobacco in the final product:

[0025] A method for measuring the mixing uniformity of shredded tobacco of a cigarette based on the present invention includes five steps of adding expanded shredded tobacco, sampling, separating the expanded shredded tobacco, drying, and calculating the uniformity. The specific steps are as follows:

[0026] (1) Adding expanded shredded tobacco: Table 1 shows the formulas of A and B brand cigarettes. Both cigarette brands contain expanded shredded tobacco, and the densities of the expanded shredded tobacco are 0.56g / cm 3 , 0.52g / cm 3 , so it can be directly sampled without additional addition;

[0027] (2) Sampling: The time for a batch of A and B brand materials is 6 hours and 10 hours respectively, and 1 pack is taken at intervals of 24 minutes and 40 minutes respectively at the exit of the cigarette machine, 15 bags for each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com