Instrument pointer image identification method of high-robustness rod

A technology for instrument pointer and image recognition, which is applied in the field of image processing, can solve problems such as difficult to extract scale lines, difficult to locate instruments, and high environmental requirements, and achieve the effects of reducing human subjective error factors, good robustness, and improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

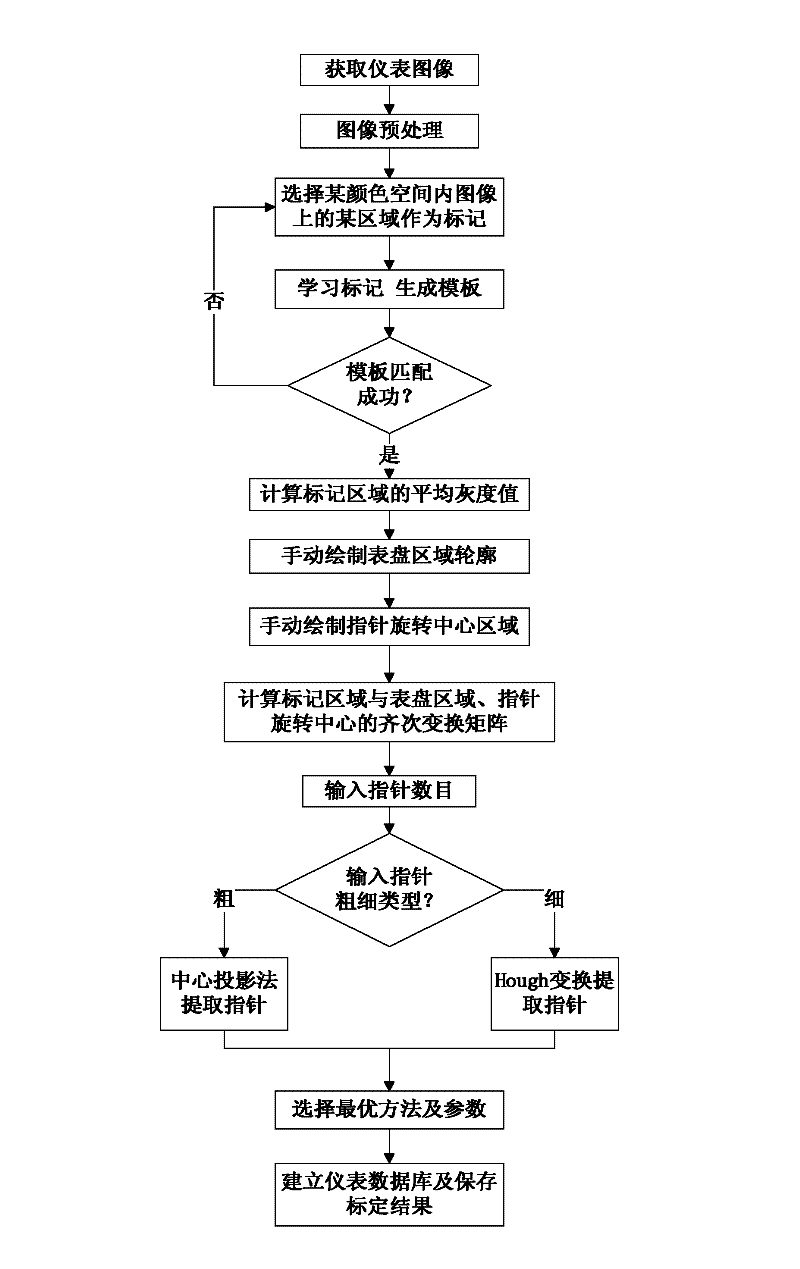

[0029] like figure 2 As shown, the highly robust instrument pointer image recognition method provided by the present invention includes the steps of the offline calibration stage and the online recognition stage executed in sequence. The steps in the offline calibration stage include: adjusting the camera so that it is aimed at the instrument panel, and image acquisition (step 101); image preprocessing is performed on the collected image (step 102); an area is taken as a mark on the image, Carry out mark study (step 103); After instrument position calibration (step 104), instrument characteristic study (step 105), determine pointer recognition method and pointer recognition parameter (step 106), and set up database and demarcate result is preserved (step 107 ). The steps in the online identification stage include: first image acquisition (step 101), after image preprocessing (step 108) is performed on the collected image, an image that only includes the dial area is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com