Method and device for production of plasma display panel

A plasma display screen and installation part technology, which is applied in the manufacture of discharge tubes/lamps, cold cathodes, electrode systems, etc., can solve the problems of complicated exhaust pipe manufacturing process, low production efficiency, and high manufacturing cost, and achieves a reduction in Steps to install vent holes, improve product quality, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

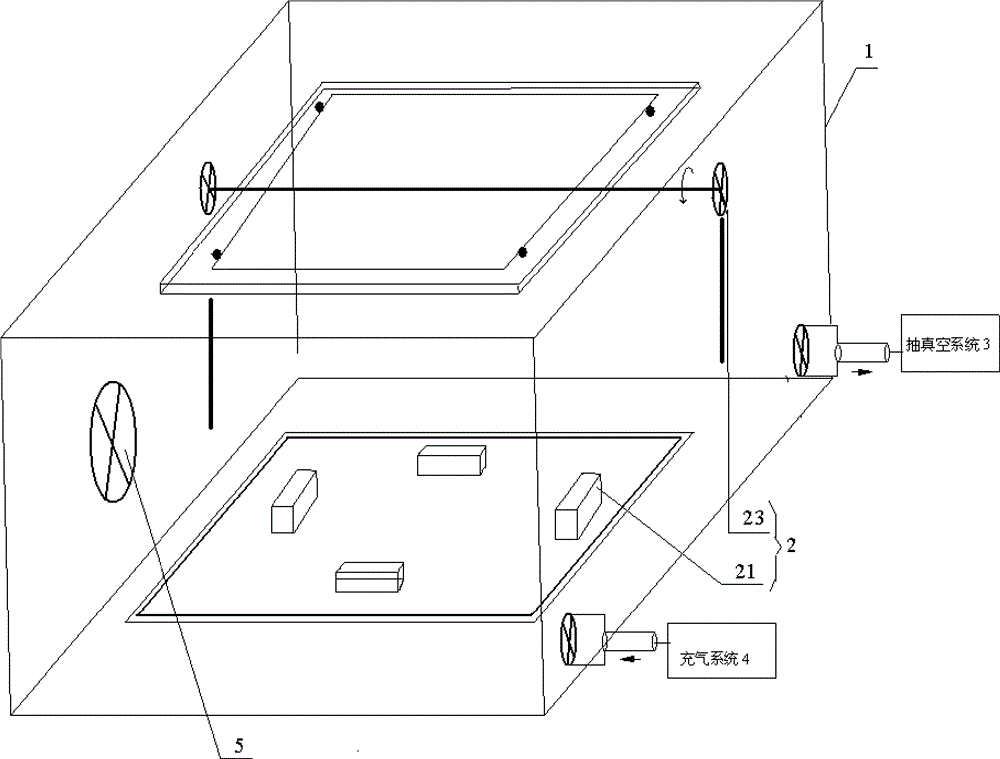

[0022] In a typical implementation of the present invention, a method for preparing a plasma display screen includes the following steps: coating an adhesive on the surface to be sealed of the upper substrate and the lower substrate, and coating the upper substrate and the lower substrate The side with the adhesive is placed upwards in a closed space; the upper and lower substrates coated with the adhesive are subjected to the first temperature rise-cooling treatment, and the airtight The space is vacuumed for the first time; the upper substrate after cooling is turned over 180 degrees, and it is combined with the lower substrate, and the confined space is vacuumed for the second time; The working gas is filled in the space; the upper substrate and the lower substrate filled with the working gas are subjected to a second temperature rise-cooling treatment, so that the upper substrate and the lower substrate are sealed together.

[0023] In the method for preparing a plasma dis...

Embodiment 1

[0034] Plasma display screen: 60 inches.

[0035] Preparation:

[0036] Coating adhesive on the surfaces to be sealed of the upper substrate and the lower substrate, and placing the upper substrate and the lower substrate with the side coated with the adhesive facing up in a closed space

[0037] Heat the upper substrate and lower substrate coated with the adhesive to 420°C, keep it warm for 25 minutes, then cool it down to 360°C at a rate of 2°C / min, and keep it for 3 hours (the first temperature rise-cooling treatment), And at the same time of the first heating-lowering treatment, the confined space is vacuumed for the first time, and the vacuum degree is 2.0×10 -4 Pa.

[0038] Turn the lowered upper substrate over 180 degrees, put it together with the lower substrate, and perform a second vacuuming treatment on the enclosed space, with a vacuum degree of 3.5×10 -3 Pa.

[0039] After the second vacuuming process is completed, the airtight space is filled with working gas...

Embodiment 2

[0042] Plasma display screen: 60 inches.

[0043] Preparation:

[0044] Coating adhesive on the surfaces to be sealed of the upper substrate and the lower substrate, and placing the upper substrate and the lower substrate with the side coated with the adhesive facing up in a closed space

[0045] Heat the upper substrate and lower substrate coated with the adhesive to 490°C, keep it warm for 58 minutes, then cool it down to 400°C at a rate of 5°C / min, and keep it for 7 hours (the first temperature rise-cooling treatment), And at the same time of the first temperature rise-cooling treatment, the confined space is vacuumed for the first time, and the vacuum degree is 7.8×10 -4 Pa. Repeat the first heating-cooling step 2 times.

[0046] Turn the cooled upper substrate by 180 degrees, and put it together with the lower substrate, and perform a second vacuuming treatment on the enclosed space, with a vacuum degree of 4.0×10 -3 Pa.

[0047] After the second vacuuming process is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com