Cloth wrapping machine for seat backrest

A seat backrest and cloth wrapping technology is applied in the field of cloth wrapping machines to save manpower, reduce volume and ensure safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

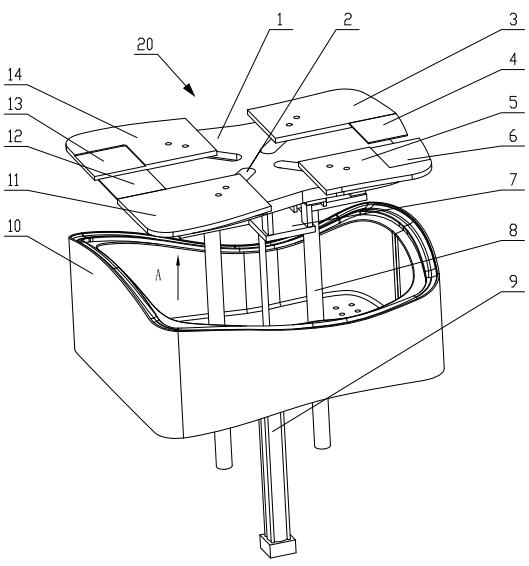

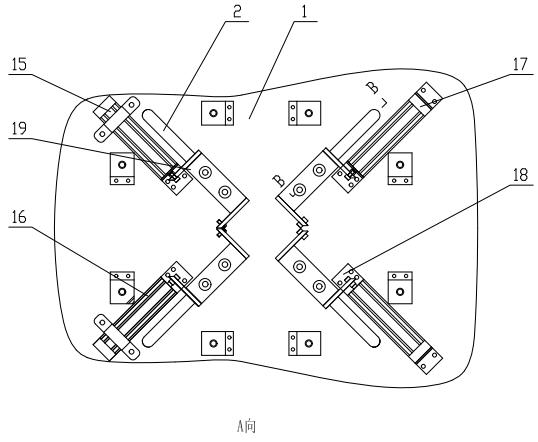

[0071] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

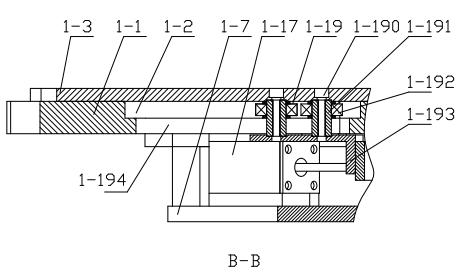

[0072] 1. Explanation of Tuobu Mechanism 1:

[0073] See figure 1 , Figure 4 As shown, the cloth support mechanism includes a cloth support platform 1-20, and the support cloth platform 1-20 is placed in the mold cavity of the lower mold 11 of the cloth wrapping machine, and is used to support the mesh cloth that needs to be flattened. The support platform 1-20 includes a support plate 1-1, the back of the support plate 1-1 is connected to the piston rod of the lifting cylinder 1-9 through the fixing frame 1-7, and the cylinder body of the lifting cylinder 1-9 and the lower mold 11 The bottom connection; there are four mutually vertical chute 1-2 on the support plate 1-1, see figure 1 , figure 2 , the slider 1-3, the slider 1-5, the slider 1-11, and the slider 1-14 are slidably embedded in the four mutually perpendicular chute 1-2 thro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap