Manufacturing method of absorbent article

A manufacturing method, absorbent technology, applied in the direction of absorbent pads, etc., can solve the problems of unsightly waist flaps, end edge fit, ugly waist flaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

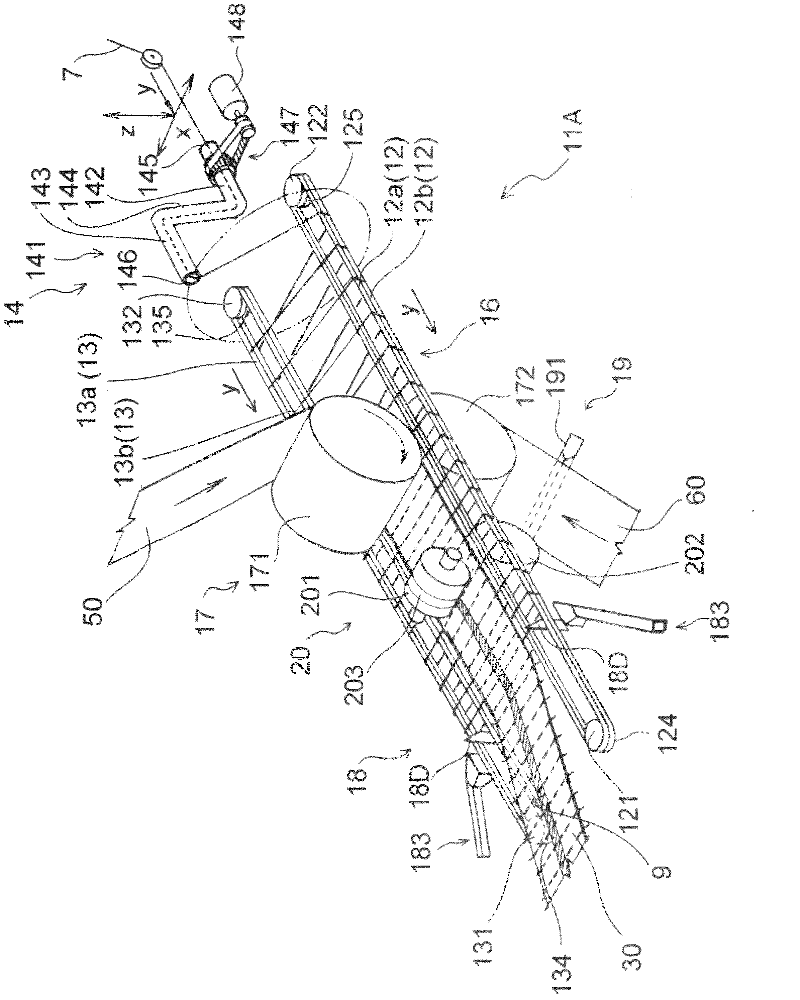

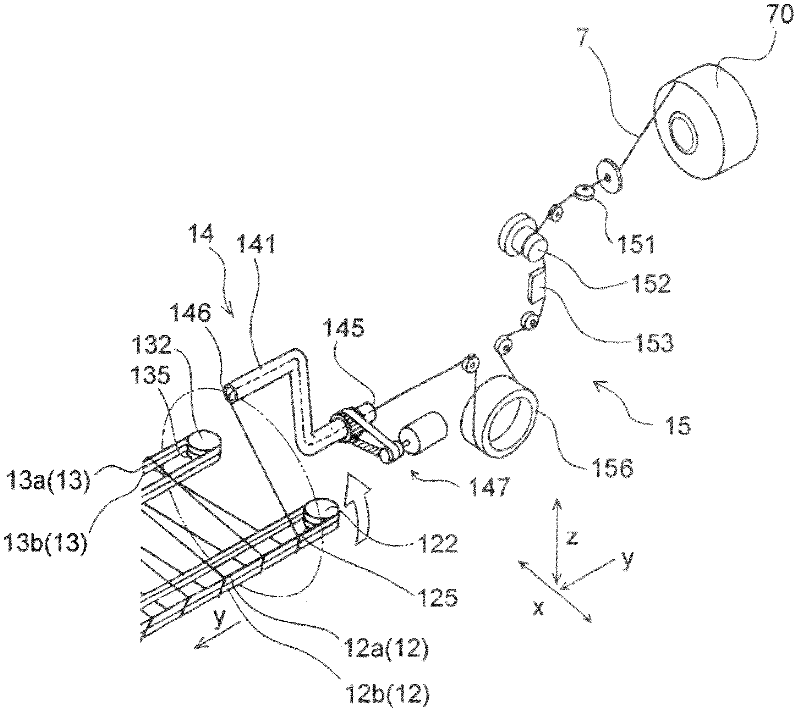

[0014] Next, the manufacturing method of the absorbent article of this invention is demonstrated based on the best mode, referring drawings.

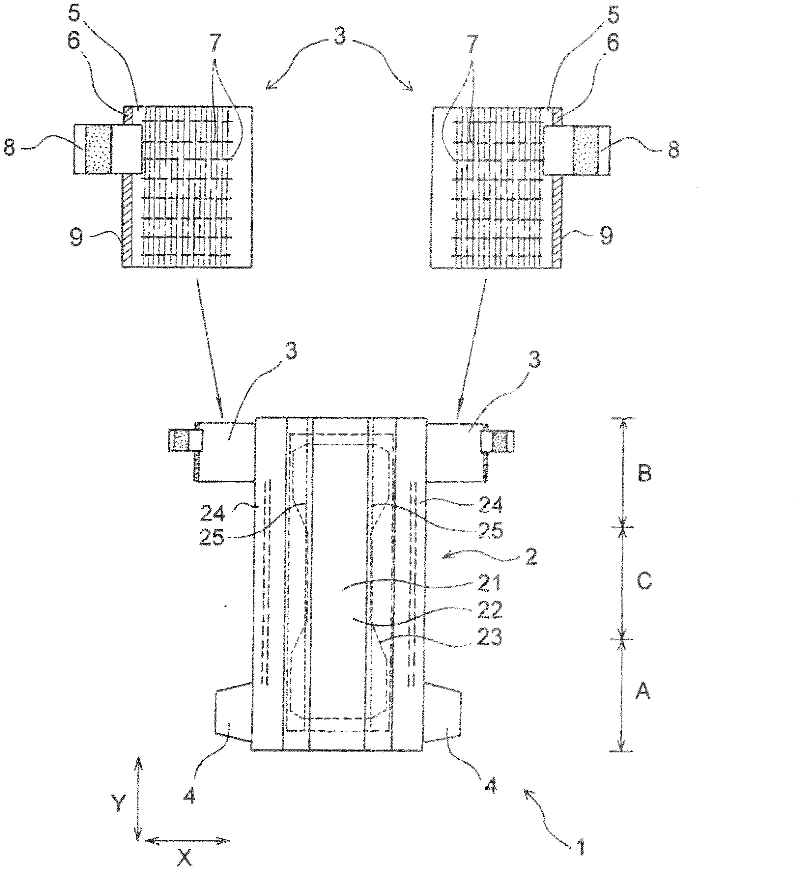

[0015] Such as figure 1 As shown, the absorbent article having the stretchable waist panels manufactured in this embodiment is, for example, an unfolded disposable diaper 1 . Therefore, first, the unfolded disposable diaper 1 (it is also called "diaper 1" hereafter) which has the stretchable waist panel 3 manufactured by this embodiment is demonstrated.

[0016] Such as figure 1 As shown, the diaper 1 comprises: an absorbent body 2 having an abdominal portion A positioned on the ventral side of the wearer when worn, a dorsal portion B positioned on the back side, and an absorbent body between the abdominal portion A and the dorsal portion B. crotch C; Such as figure 1 As shown, the diaper 1 has flap materials 4, 4 extending from both side edges of the abdominal portion A, respectively. Additionally, if figure 1 As shown, the absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com