Straight-through cloth bag dust remover built in flue

A bag filter, straight-through technology, applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of large volume and complex structure, and achieve compact equipment, reasonable structure, and long-term stable operation of protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

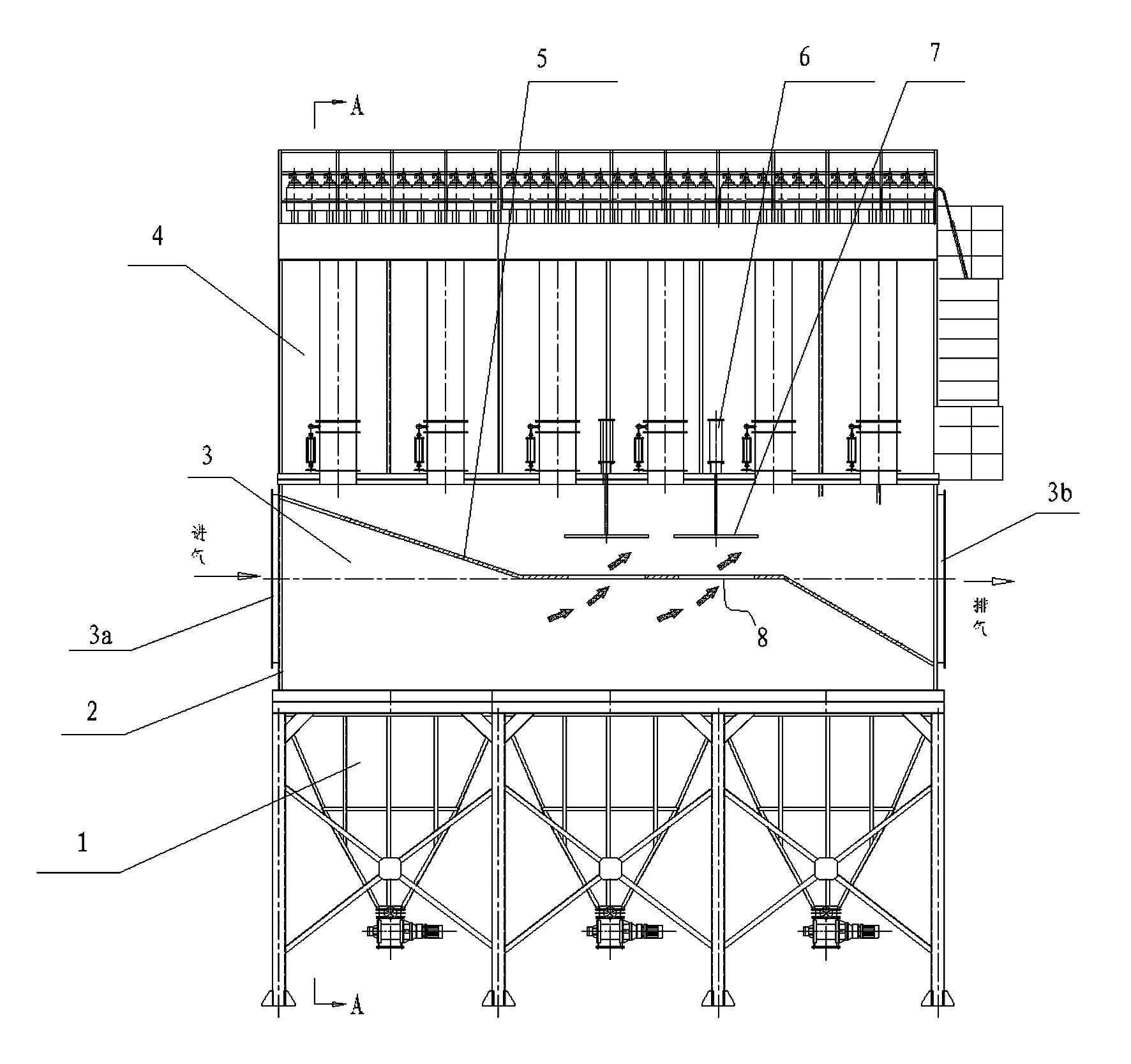

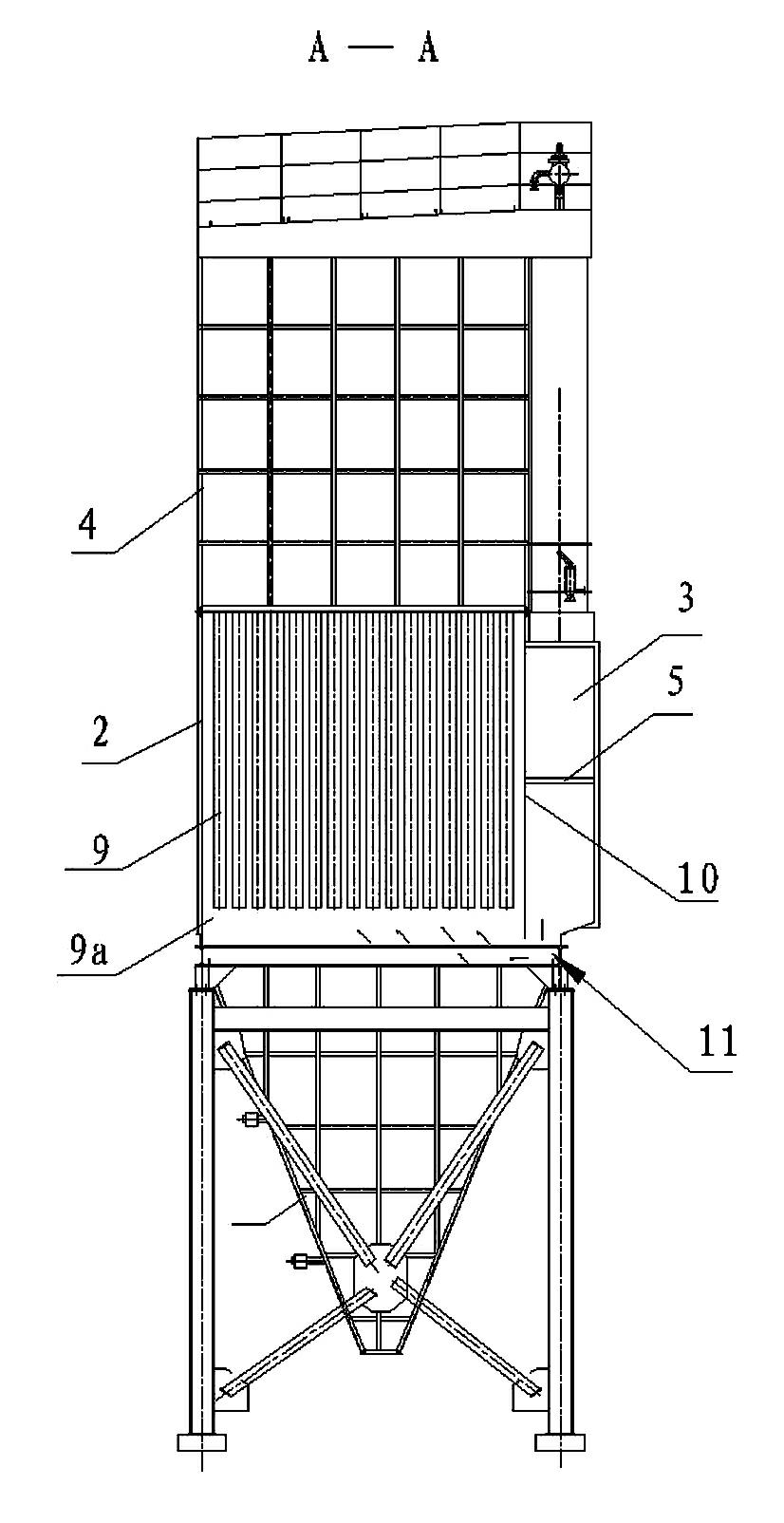

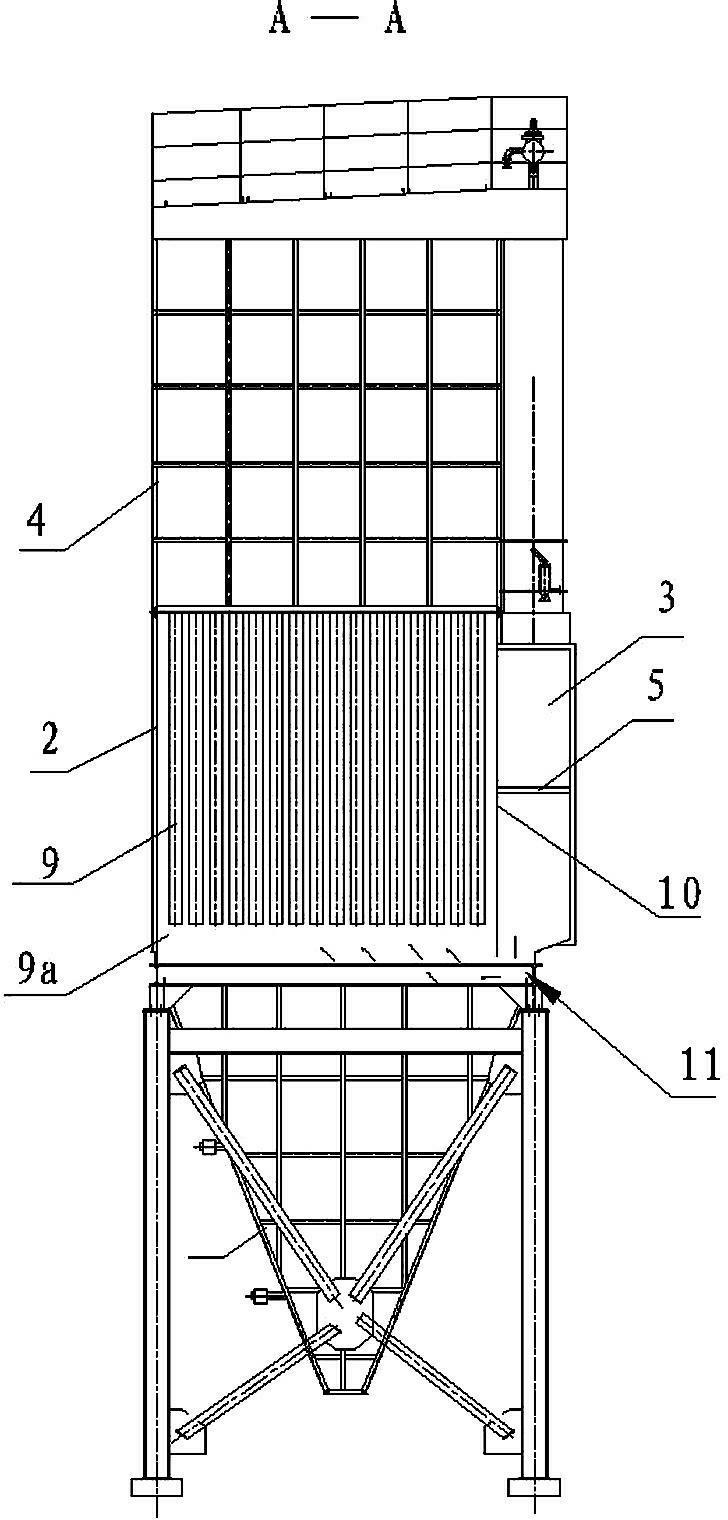

[0011] Such as figure 1 , figure 2 As shown, a kind of flue built-in straight-through bag filter provided by the present invention includes an ash hopper 1, a middle box body 2 and an upper box body 4, and a group of filter bags 9 are arranged in the middle box body 2, and the middle box body 2- A dividing plate 10 is arranged on the side, and the dividing plate 10 divides the middle casing into a bag chamber 9a and a straight-through bypass flue 3, and the lower end of the dividing plate 10 communicates with the bag chamber 9a in the middle casing, as figure 2 As shown, the flue gas 11 (as shown by the arrow) can enter the bag chamber 9a from the lower end of the partition plate 10, while the large particles of dust directly fall into the ash hopper 1 below.

[0012] Such as figure 1 As shown, the two ends of the straight-through bypass flue 3 are respectively connected to the air inlet 3a and the air outlet 3b at the front and rear ends of the middle box.

[0013] An in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap