Granulation device

A technology of sieve plates and hammers, which is applied in the field of granulation devices, can solve problems such as the performance degradation of pulverizers, and achieve the effects of increasing relative speed, low cost, and enhancing effectiveness

Inactive Publication Date: 2012-07-04

杨忠芳

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to solve the problem in the prior art that the performance of the pulverizer is reduced due to the s

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

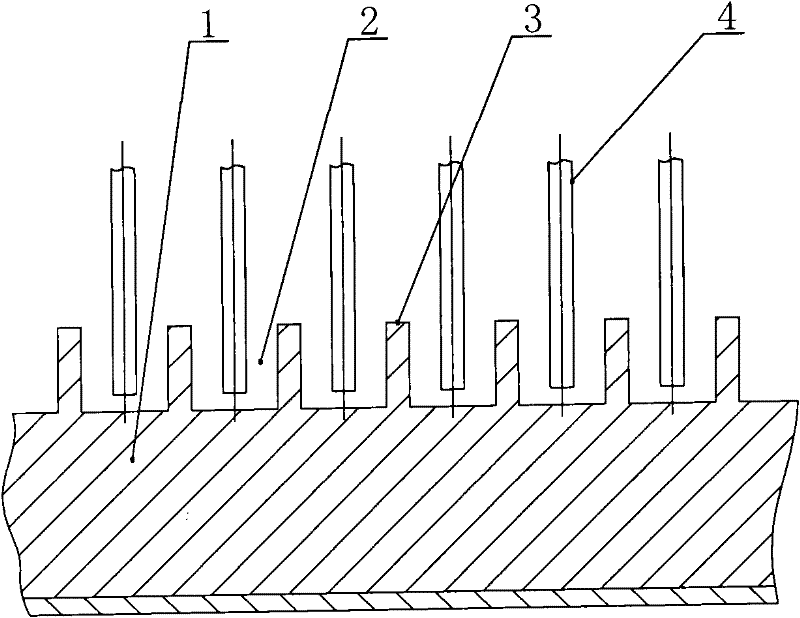

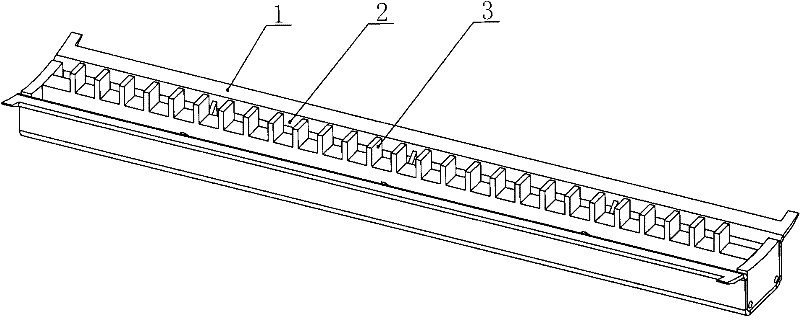

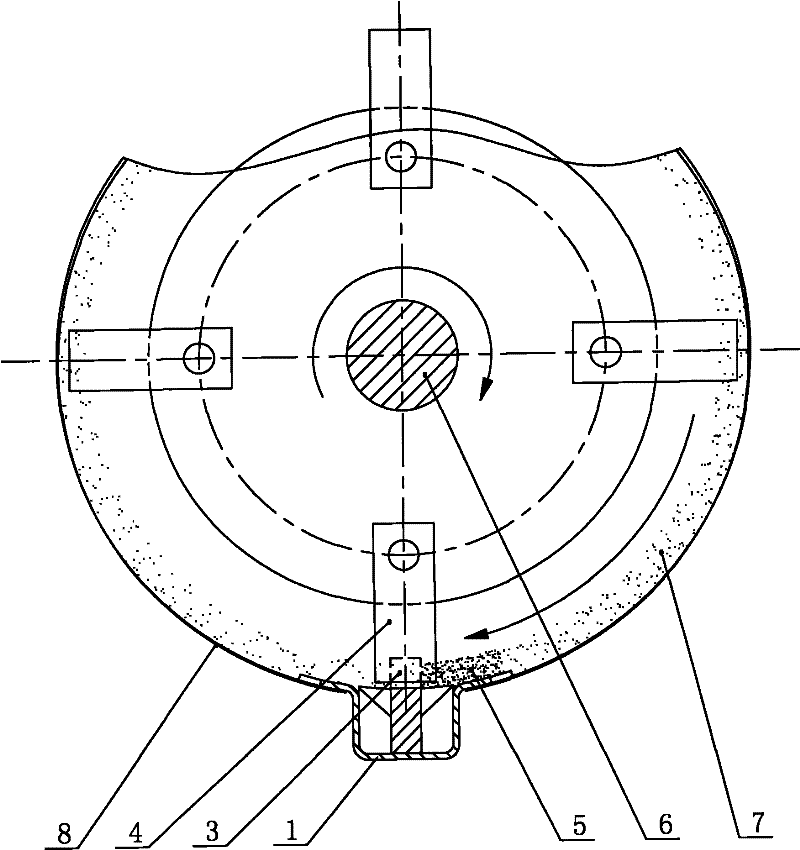

The invention discloses a granulation device, and aims at solving the problem that the performance of a crusher is reduced due to a stable circulation layer. The granulation device comprises a rotor, hammer sheets which rotate around a rotor shaft on the rotor, and sieves enclosing the hammer sheets, wherein the adjacent sieves are connected with each other through a press sieve plate; a plurality of cut ribs which are raised inward a crushing chamber; every two cut ribs are parallel to each other and vertical to the axis of the rotor shaft; a cut groove is formed between every two cut ribs; and the top end of the rotary circumference of each hammer sheet penetrates through each cut groove. When the granulation device is used, the cut ribs can retard the circulation layer, so that the hammer sheets can strike materials more effectively. The granulation device can be applied to a hammer mill, so that the efficiency of the hammer mill can be greatly improved.

Description

technical field [0001] The invention relates to a mechanical device, in particular to a granulation device. Background technique [0002] At present, hammer mills are mainly used for crushing large-diameter materials. There is a rotor in the crushing chamber, and the rotor is installed on the rotor main shaft. Both ends of the main shaft are supported on the frame through bearing seats. On the main shaft, there are a number of pin shaft holes evenly distributed on the hammer frame plate. The pin shafts are installed in the pin shaft holes. The hammer blades are installed on the pin shafts and separated from each other by spacers. The outer periphery of the rotor is provided with a dense net surrounding the rotor. There are sieves with holes, and the adjacent sieves are connected to each other by pressing the sieve plate. [0003] When the pulverizer is working, the material enters the crushing chamber, and at the same time, the external power source drives the rotor to rota...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B02C13/04B02C13/26

Inventor 杨忠芳

Owner 杨忠芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com