Vacuum classifier

A classifier and vacuum technology, applied in the field of separation, can solve problems such as difficulty in achieving 100% qualified rate of finished products, low classification efficiency, and separation effect affected by airflow fluctuations, etc., to achieve the effect of large production capacity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

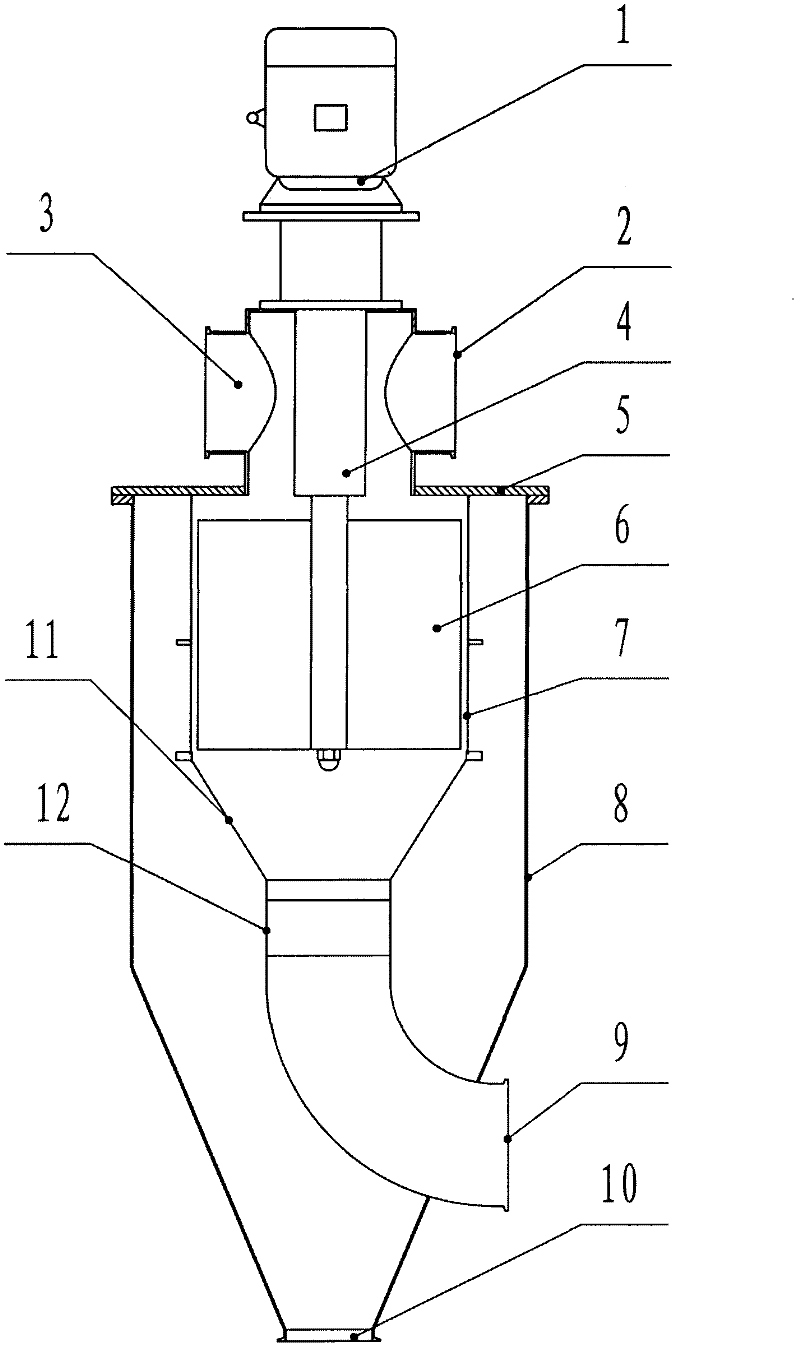

[0010] in the attached picture Among them, the impeller (6) is connected with the motor (1) through the transmission mechanism (4). A motor (1) is installed on the top of the feeding bin (3), and the bottom is fixed on the loam cake (5). The upper part of the coarse powder bin (11) is connected with a cylindrical sieve (7), and the cylindrical sieve (7) is installed on the loam cake (5). A soft connection (12) is provided between the coarse powder bin (11) and the coarse powder bin outlet (9), the fine powder bin (8) is outside the cylindrical sieve (7) and the coarse powder bin (9), and the upper cover (5) be installed on the top of the fine powder bin (8).

[0011] When replacing the cylindrical sieve (7), first the soft connection (12) is opened, and the loam cake (5) and the connection part are lifted, and then the cylindrical sieve (7) can be disassembled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com