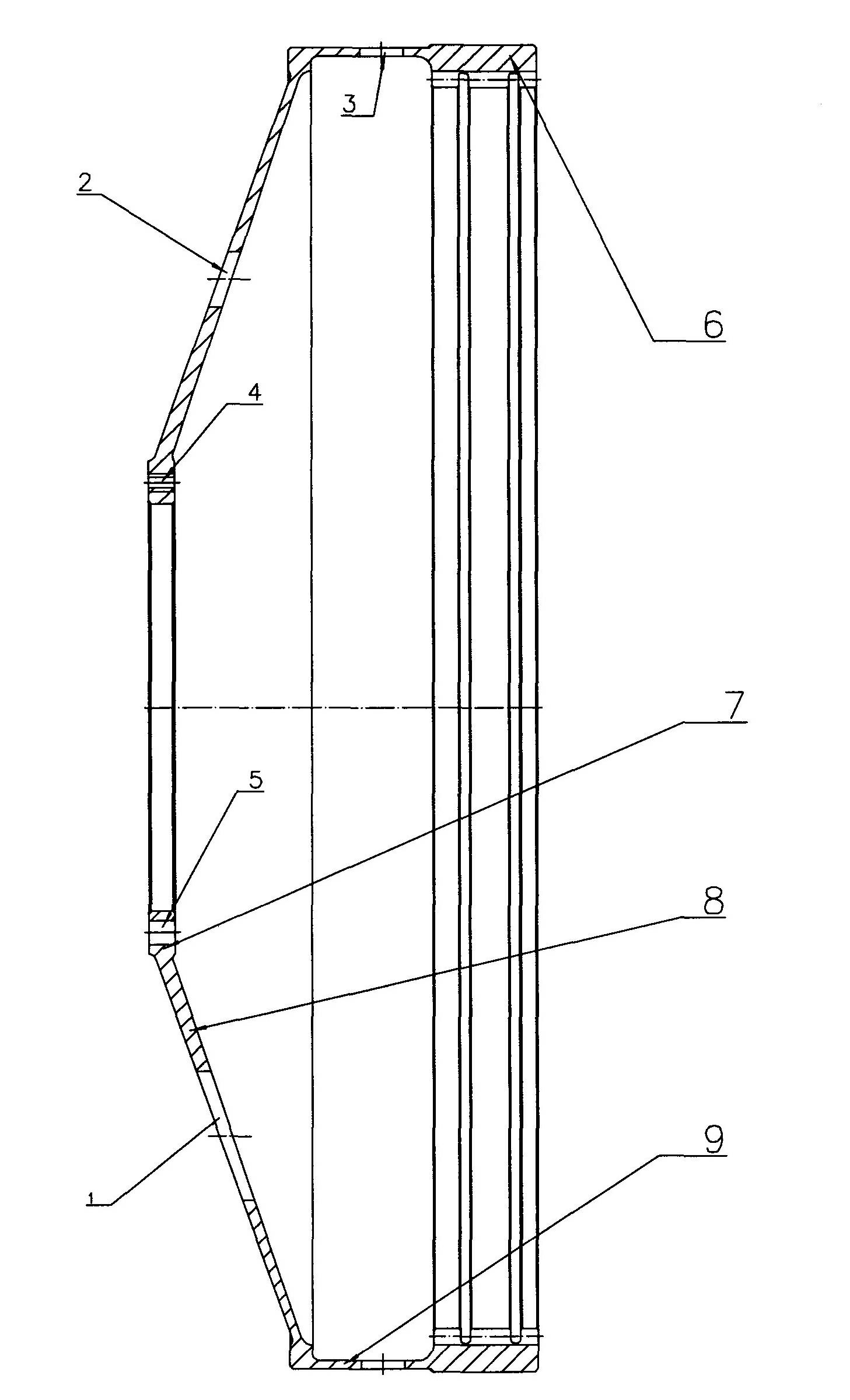

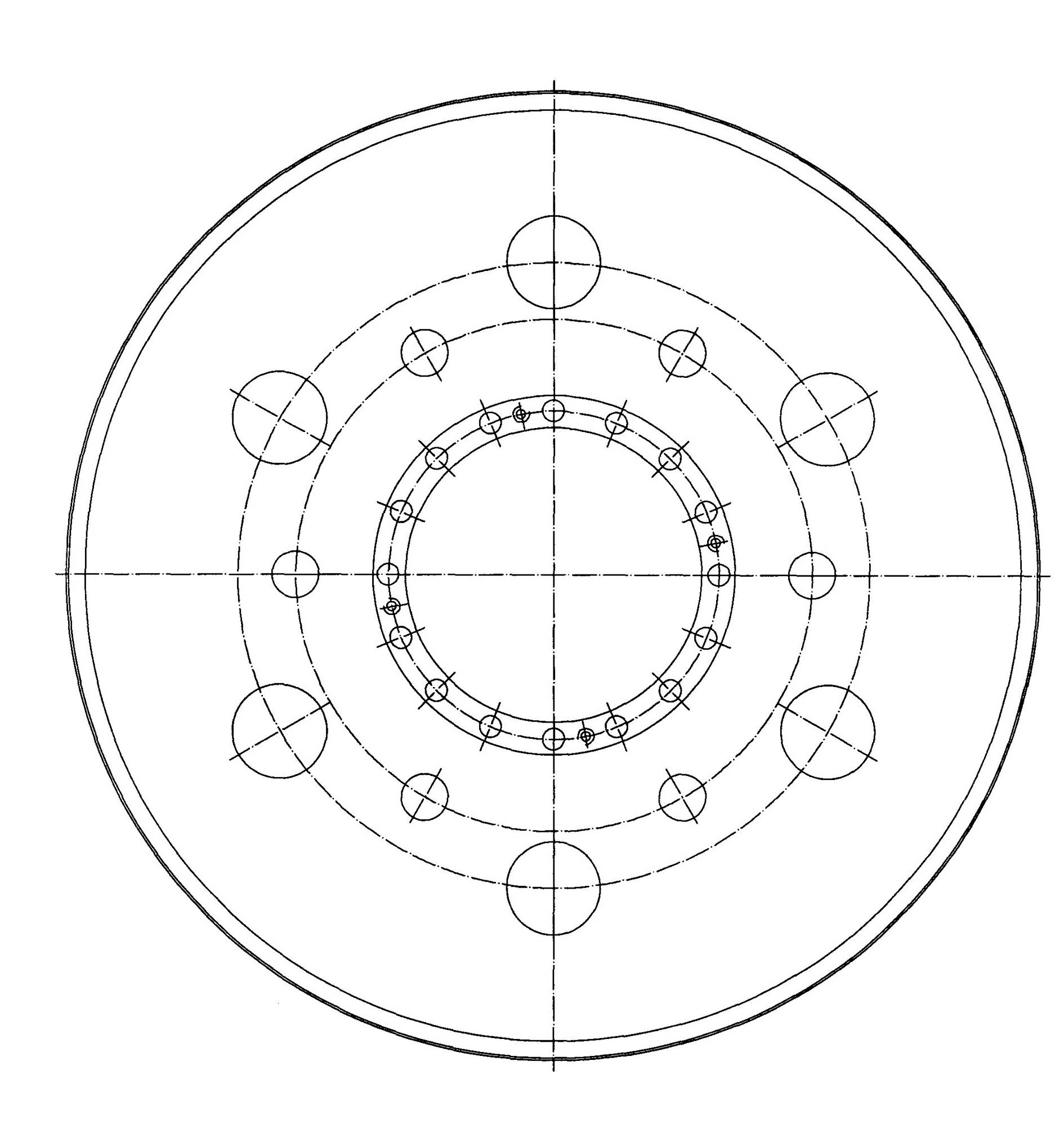

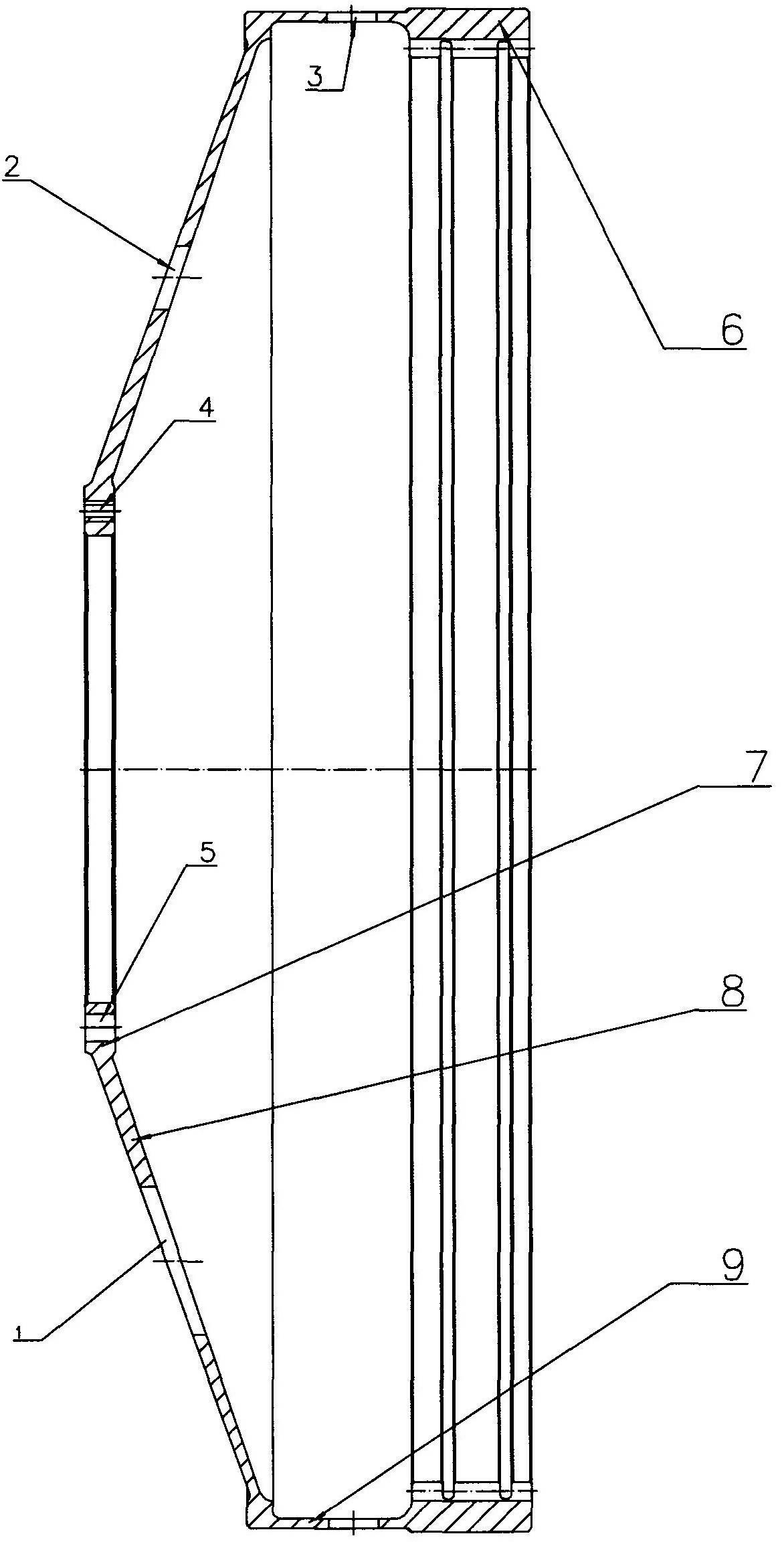

Process for machining thin-walled precision internally-toothed sleeve with flange, cone and transition ring

A processing technology and technology of inner gear sleeves, which are applied in the field of processing technology of transmission parts, can solve the problems of deformation gear accuracy, reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0035] A processing technology for thin-wall precision internal gear sleeves with flanges, cones and transition rings. The blank is forged with high-strength alloy structural steel, and the surface of the internal gear is heat-treated for nitriding treatment. The depth of the nitriding layer is 0.3-0.5, and the surface hardness is ≥ HV650. , core hardness HB283-341;

[0036] a. After forging, the rough car is basically formed, leaving a margin for semi-finish and finish cars;

[0037] b. Ultrasonic flaw detection to ensure that the quality level of internal defects of parts meets the requirements;

[0038] c. The overall quenching and tempering treatment, the hardness is HB303-360, so as to ensure that the hardness of the core part of the part meets the requirements;

[0039] d. The semi-finished car is basically formed, leaving a margin for the finished car;

[0040] e. The first stress relief treatment;

[0041] f. The first finish turning, the inner and outer dimensions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com