Rotary electric shaver and manufacturing method of outer cutter and inner cutter of the same

A rotary, cutter technology, applied in other manufacturing equipment/tools, manufacturing tools, metal processing, etc., can solve the problems of decreased productivity, deterioration of processing efficiency, complex processing, etc., to achieve easy assembly, good efficiency, and increased shaving area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

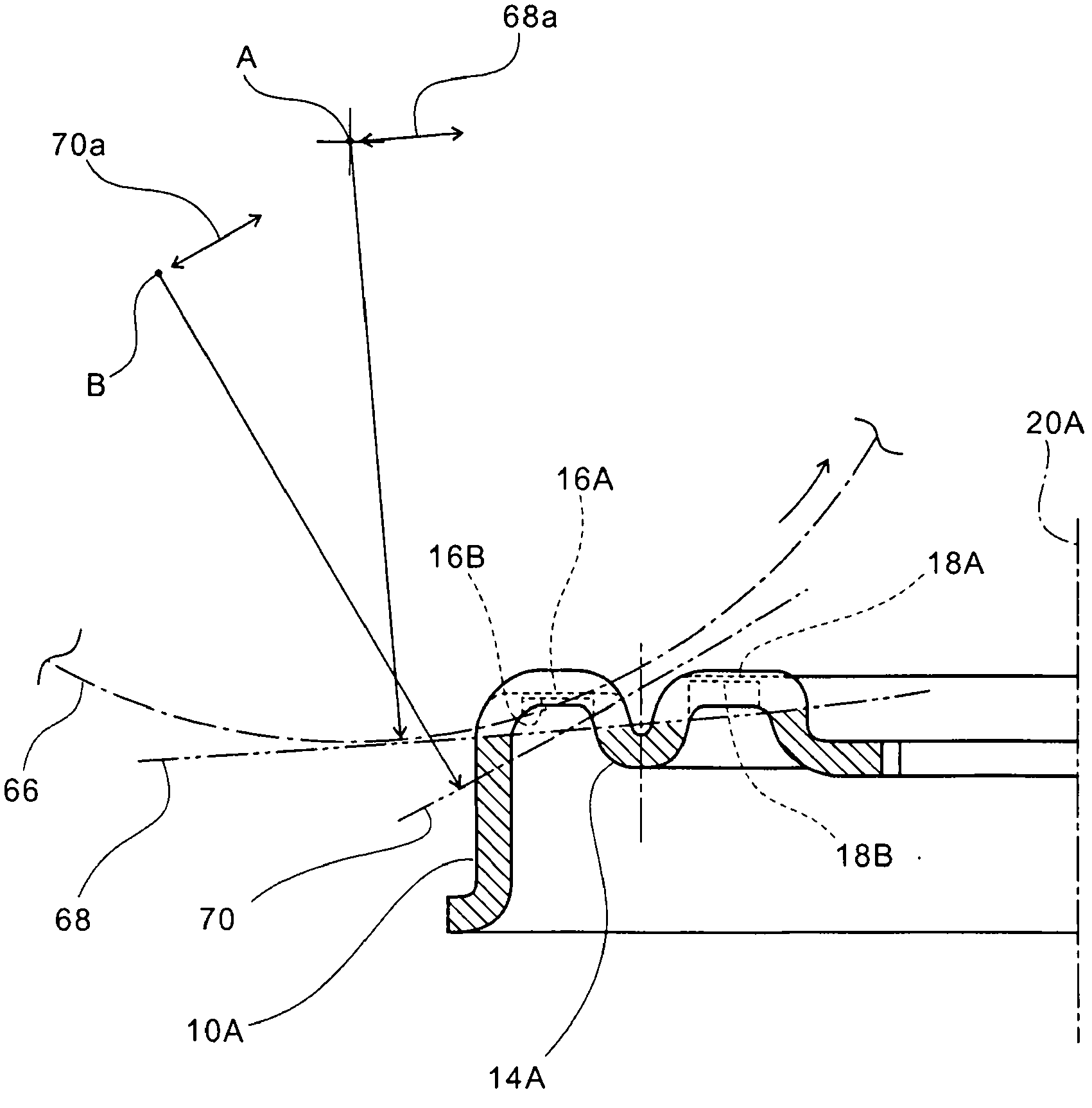

[0025] The annular shaving surface formed on the outer cutter may be a double concentric circle or a triple concentric circle. The beard entrance formed on the shaving surface of the outer cutter may be in the shape of a slit. If it is in the shape of a slit, when performing the machining of the outer tool described later, the rotating disc grinding wheel rotating around the horizontal axis can be moved toward its radial direction or the rotating disc grinding wheel can be slightly tilted towards its radial direction. The entire circular shaving surface is processed efficiently in one process.

[0026] On the inner cutter, it is possible to cut off (punching up (Japanese: 切りこし)) on a common metal plate, and integrally form a plurality of small cutters corresponding to all annular shaving surfaces with different radii of rotation, In this case, the structure of the inner cutter is also simplified. At this time, the center of rotation moves up and down (in a direction parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com