High-speed cap separating mechanism

A high-speed, cover-separating technology, which is applied in the direction of object destacking, transportation and packaging, can solve the problems of low efficiency and high labor intensity, and achieve the effect of low cost, easy realization and high efficiency of cover separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

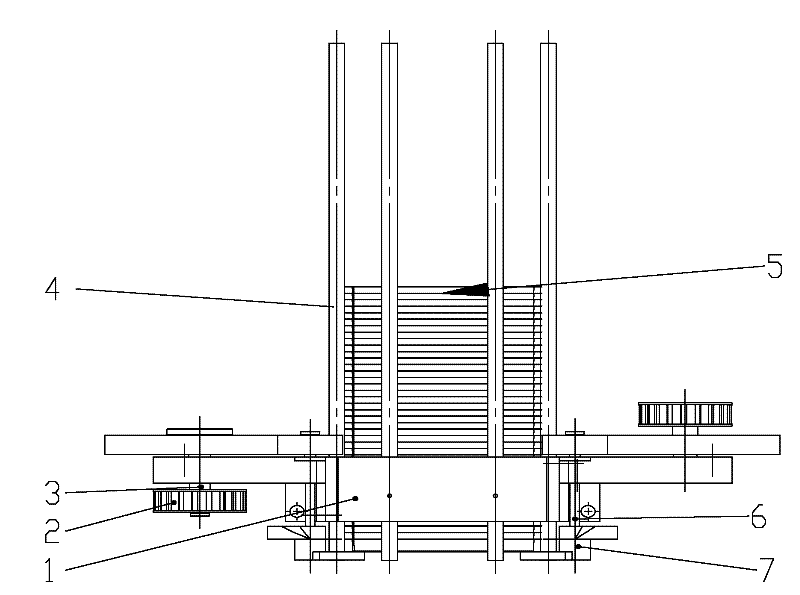

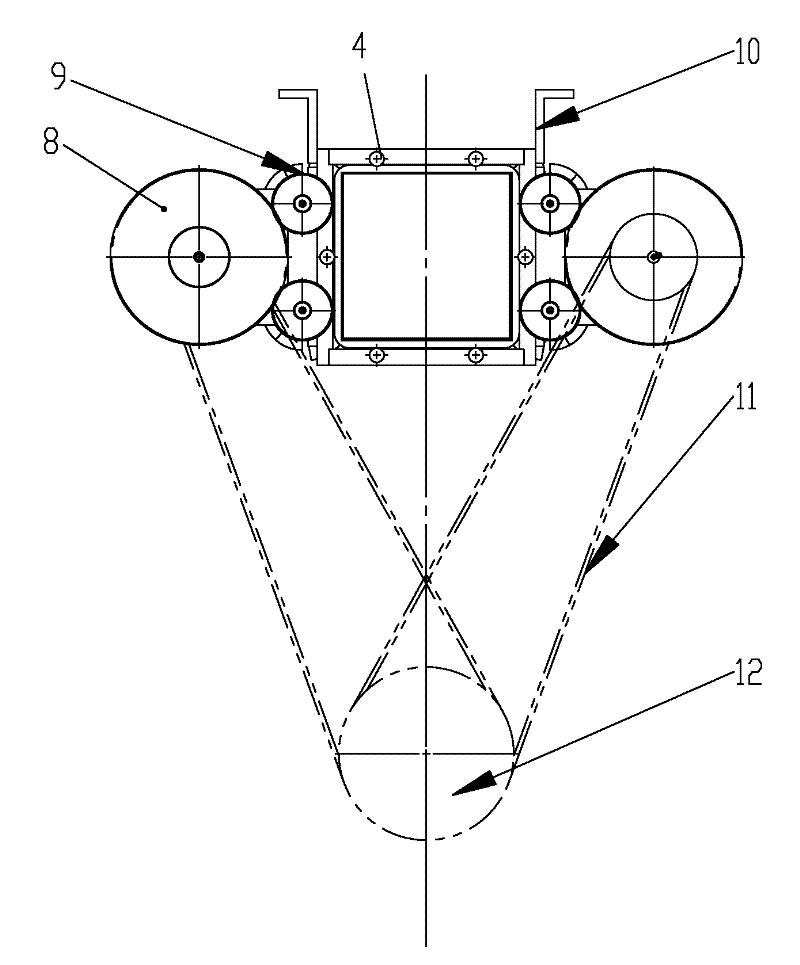

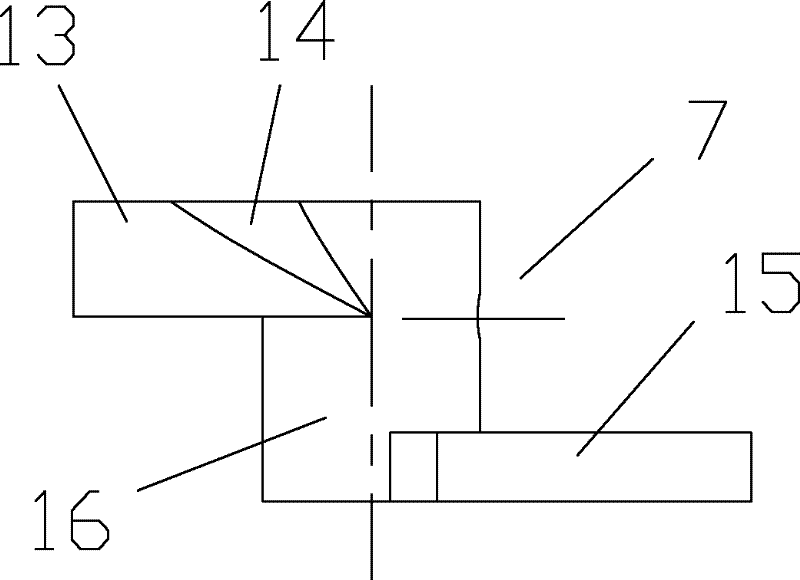

[0022] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the sub-cover seat 1 is installed on the mounting bracket 10, and the 6 cover bin guide rods 4 are vertically installed in the holes of the sub-cover seat 1 whose shape is adapted to the shape of the sealed can lid. touch. There are 4 sub-cover parts installed on the bottom of the cover bin. The sub-cover part is a double-layer dial, which is composed of an upper wheel 13 and a lower wheel 15 connected by a central bushing 16. The projection of the lower wheel 15 is a sector with a central angle of less than 180 degrees. , the upper surface is a plane, the projection of the upper wheel 13 is fan-shaped, and the central angle is 180 ± 10 degrees. The upper and lower fan-shaped symmetry lines of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com