Ball guide shoe

A ball and guide shoe technology, which is applied in the direction of elevators, transportation and packaging, etc., can solve the problems of large fit gap between guide shoes and guide rails, car shaking, impact, etc., and achieve simplified lubrication and maintenance, saving maintenance costs and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

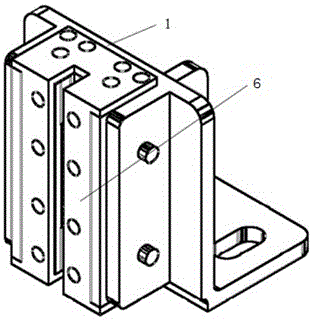

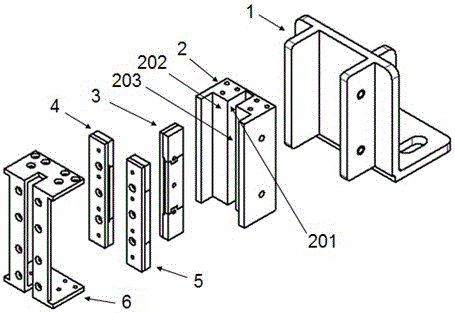

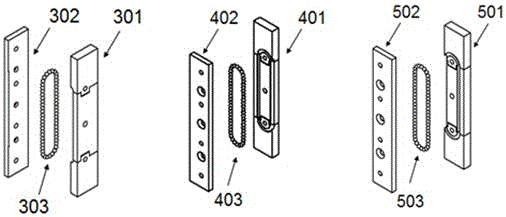

[0020] Such as figure 1 , figure 2 with image 3 As shown, the present invention includes a guide shoe seat 1, on the guide shoe seat 1, a fixed bracket 2 is set by a bolt, and the fixed bracket 2 has two middle elevations 203 and two side planes 202, and the center of the fixed bracket 2 is longitudinally passed through a screw The vertical guide system 3 corresponding to the working top surface of the guide rail 7 is set, and the vertical guide system 3 is located in the two middle facades 203 of the strip shape. The vertical guide system 3 is arranged on the ball rack A301 by the ball rack A301. The ball A303 on the top and the ball cover A302 installed on the ball frame A301 by bolts, on the planes 202 on both sides of the fixed frame 2, the left guide system 4 and the right guide system 5 corresponding to the working side of the guide rail are set by screws, The left guide system 4 is composed of the ball frame B401, the ball cover B402 fixed on the ball frame B401 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com