Lifting appliance

A spreader and hook technology, which is applied in the field of spreaders, can solve the problems of low operating efficiency, high risk factor, high labor intensity, etc., and achieve the effects of convenient operation, low cost, and reduced safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

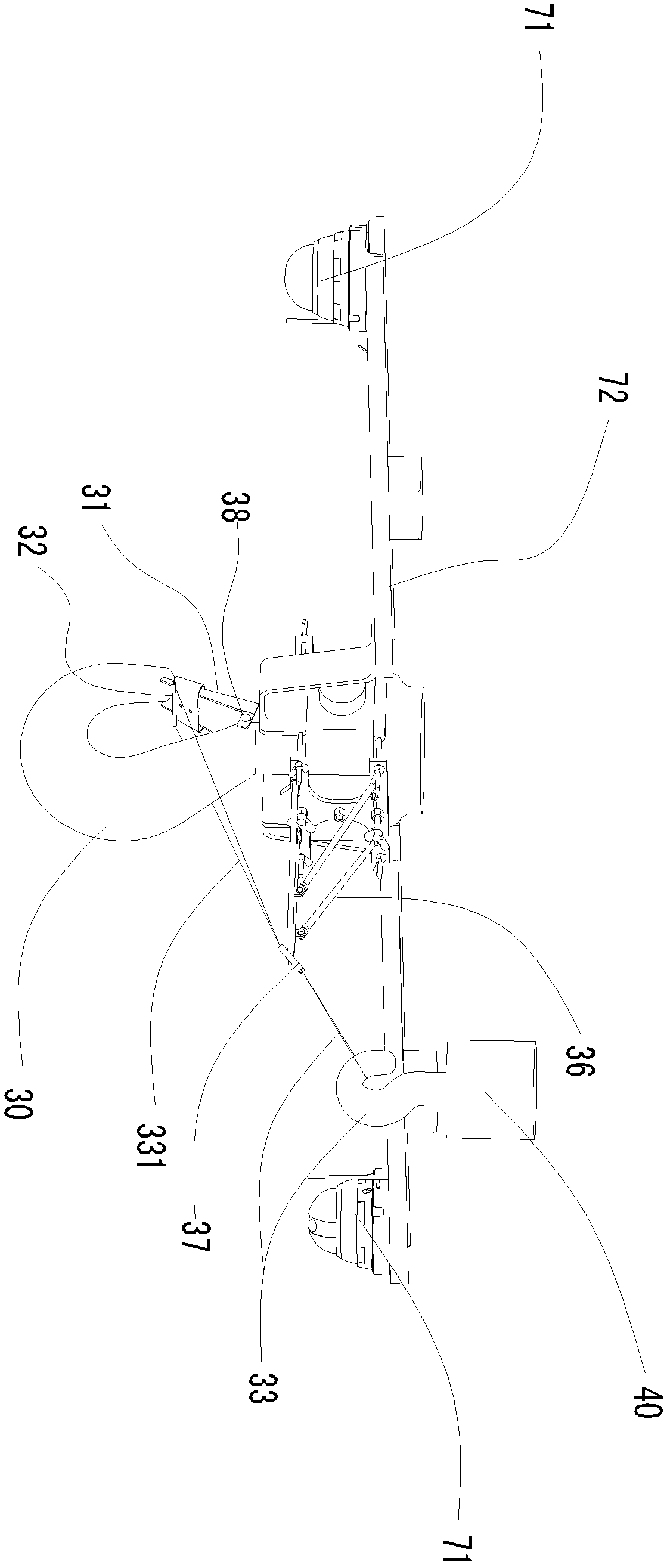

[0082] Such as figure 2 , image 3 and Figure 5 As shown, the hanger of the present invention includes a first hook 30 provided with a blocking device 31, wherein one end of the blocking device 31 is hinged to the first hook 30, and the other end of the blocking device 31 is connected to the opening end 34 of the first hook. The inner connection, that is, the inner side of the first hook opening end 34 limits the blocking device 31 to its inner side. An elastic reset device 38 is arranged between the blocking device 31 and the first hook 30 . The elastic reset device 38 here is a torsion spring, which can push the movable end of the blocking device 31 to the inner side of the opening end 34 of the first hook for compression. A flexible traction device 33 is disposed between the blocking device 31 and the first hook 30 , and the flexible traction device 33 stretches the blocking device 31 along the inner side of the first hook 30 . Flexible traction device 33 comprises tra...

Embodiment 2

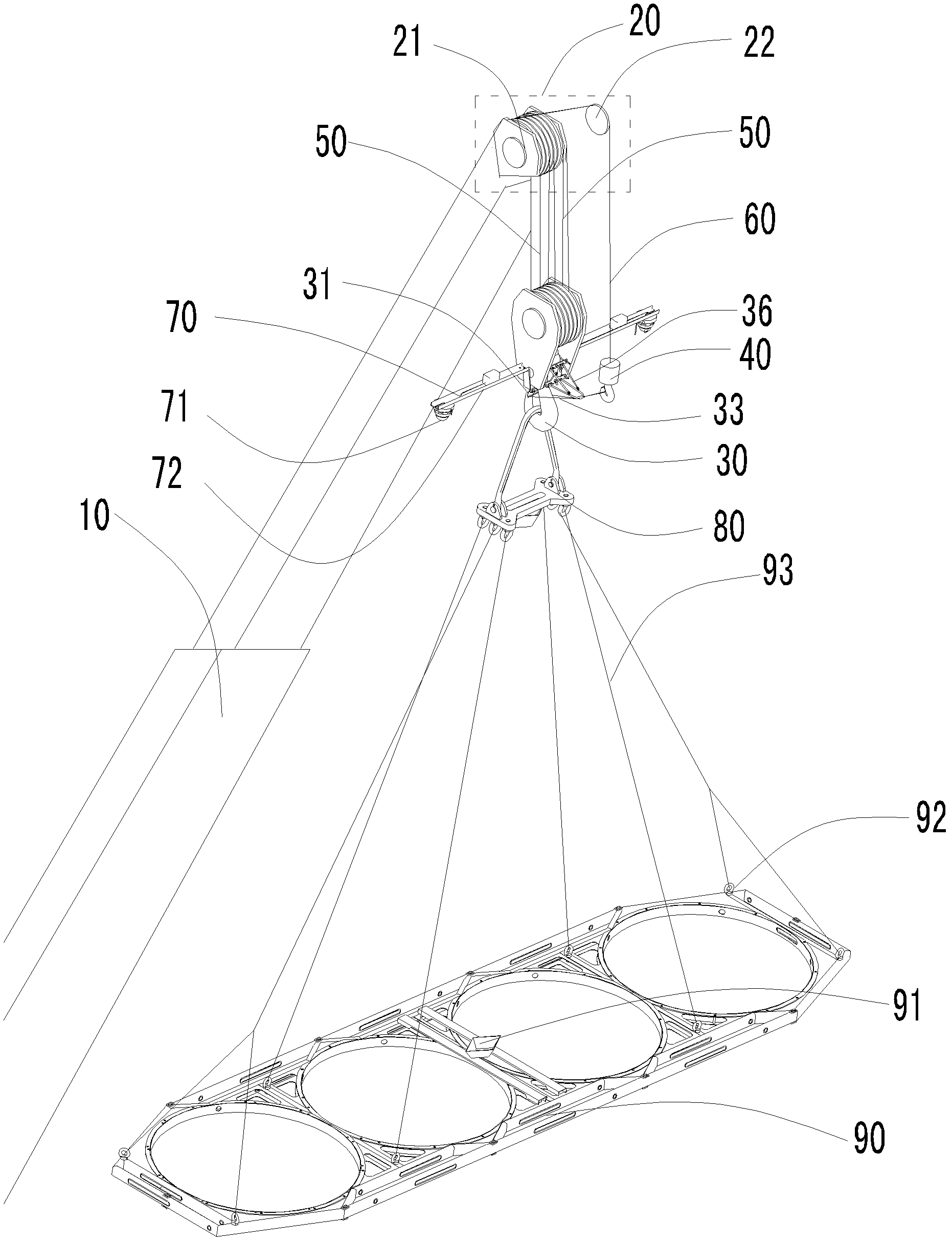

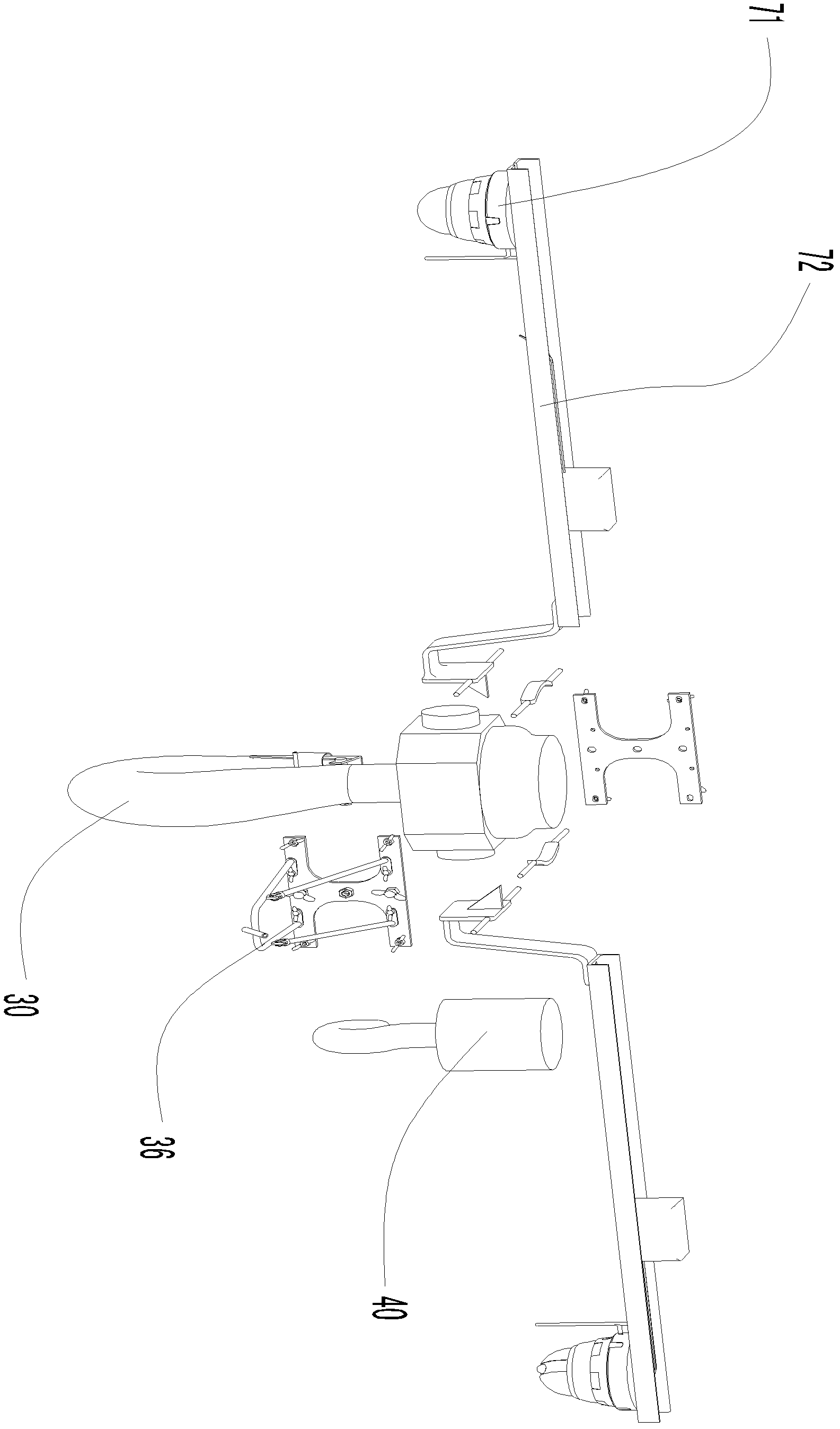

[0084] Such as Figure 1 to Figure 6 As shown, the flexible traction device 33 includes a second hook 40 and a traction rope 331, the traction rope 331 is sleeved in the second hook 40, and the first hook neck 35 is located at the opening end of the second hook 40 and the first hook. 34, the first hook 30 and the second hook 40 are suspended on the support arm 10, the support arm 10 is provided with a pulley block 20, the pulley block 20 is arranged on the top of the support arm 10, and the pulley block 20 includes the first pulley 21 and The second pulley 22, the first pulley 21 and the second pulley 22 are all arranged on the support arm 10, the first suspension hook 30 is suspended below the first pulley 21 by the first suspension rope 50, and the first suspension hook 30 passes through the first The suspension rope 50 is connected with the first pulley 21 in the form of a movable pulley, and the height of the first suspension hook 30 can be adjusted through the first suspe...

Embodiment 3

[0087] Such as Figure 1 to Figure 6 As shown, the first suspension hook 30 is provided with a camera assembly 70, the camera assembly 70 includes a camera 71 and a connecting rod 72 for fixing the camera 71, the camera 71 is arranged on both sides of the first suspension hook 30 through the connecting rod 72, connected Rod 72 is fixed on both sides of the first suspension hook 30, and is used for monitoring the operating condition of the spreader, so that the operator can know in time, and the camera 71 is movably connected with the end of the connecting rod 72, so that the camera 71 can do 360° on the horizontal plane. rotate.

[0088] Lifting ring assembly 80 is hoisted on the first suspension hook 30, and lifting ring assembly 80 comprises base body 81 and the suspension ring 82 that is arranged on base body 81 bottom, is hinged with lifting ring 83 on base body 81, makes base body 81 can rotate in horizontal direction, and suspension ring 82 It is arranged on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com