Telescopic system for crane boom and jib

A technology of boom and jib, which is applied in the field of boom telescopic system to achieve cost saving, high payload and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

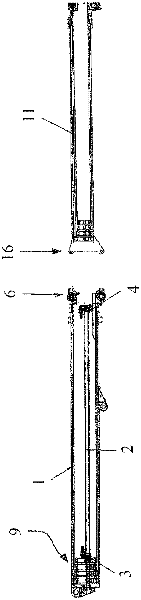

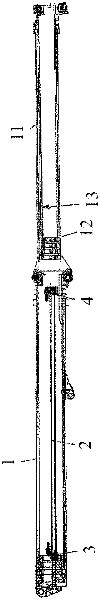

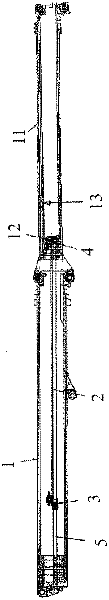

[0020] figure 1 And the jib system shown in other drawings includes a main jib 1 and an auxiliary jib 11 . The base 9 of the main boom 1 is pivotally connected (not shown) to the superstructure of a crane, in particular a mobile crane or a truck crane, which, in addition to the outer base portion or bottom of the main boom 1, includes a The four telescopic parts protruding, the four telescopic parts are in figure 1 not indicated separately. The auxiliary arm 11 also includes four telescopic parts that can be stretched out, figure 1 In , the connecting piece 6 of the head of the inner telescopic piece of the main arm 1 and the connecting piece 16 of the root of the outer telescopic piece of the auxiliary arm 11 are additionally indicated. Incidentally, the connection piece 6 is the same as, for example, the connection piece used to connect the luffing jib to the main boom 1 .

[0021] in addition, figure 1 Shown in the telescopic cylinder 2, the telescopic cylinder 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com