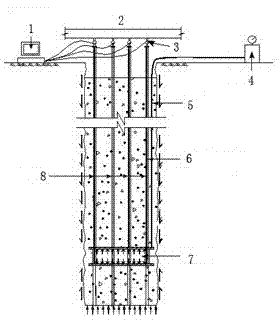

Construction method of self-balancing method pile foundation bearing capacity test device

A technology of test device and construction method, which is applied in the test of foundation structure, foundation structure engineering, sheet pile wall, etc. It can solve the problems of too thick mud, floating of steel cage, long time for installing load box, etc., and achieve the integrity of pile foundation Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

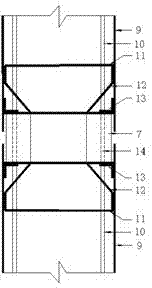

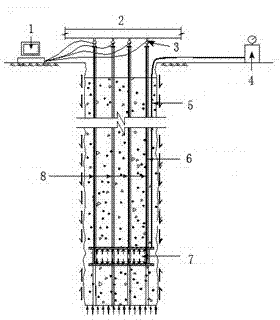

[0015] Embodiments of the present invention: the method includes the following processes: the first, construction preparation, including calculating the position of the balance point of the self-balancing method measuring pile according to requirements, determining the number of measuring piles, drilling, clearing the hole, and detecting the verticality of the hole; 2. Fabricate the load box and weld it with the steel cage; 3. Install the steel cage; 4. Clear the hole again; 5. Concrete pouring;

[0016] First, construction preparation.

[0017] (1) Calculate the position of the balance point of the piles measured by the self-balancing method according to the design and specification requirements, and determine the number of piles to be measured.

[0018] (2) Construct the pile foundation according to the design drawings to prevent partial and inclined holes; pay attention to the water head in the hole to prevent the hole from collapsing in reverse, and pay attention to cleari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com