Valve for vacuum process

一种真空工艺、阀体的技术,应用在升阀、阀细节、阀装置等方向,能够解决泵问题、减少装置使用寿命等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

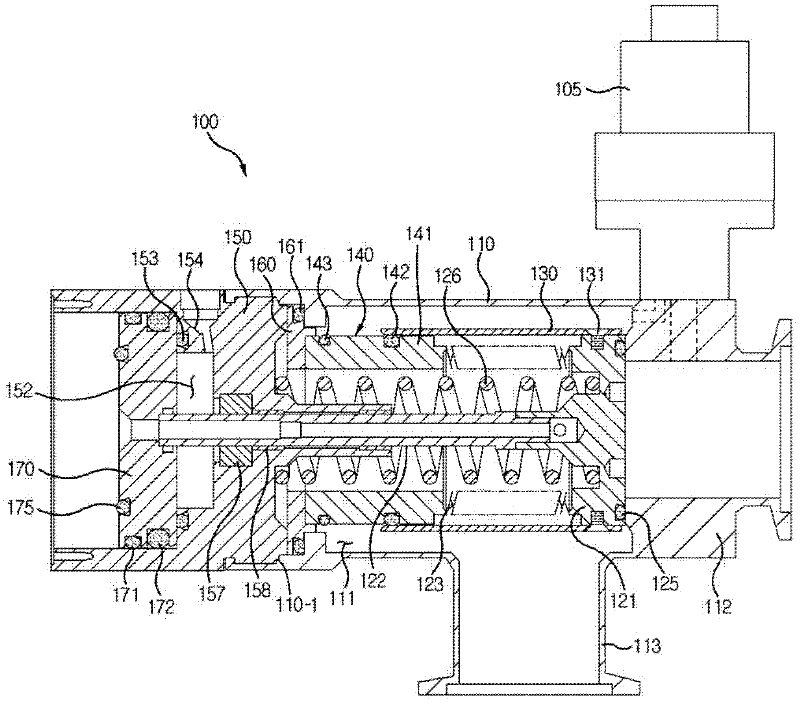

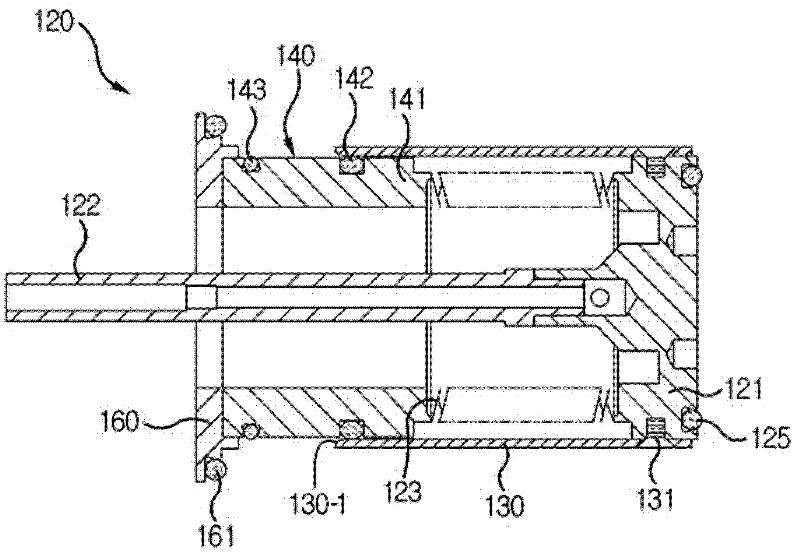

[0027] Hereinafter, a valve for a vacuum process according to an exemplary embodiment will be described in detail with reference to the accompanying drawings.

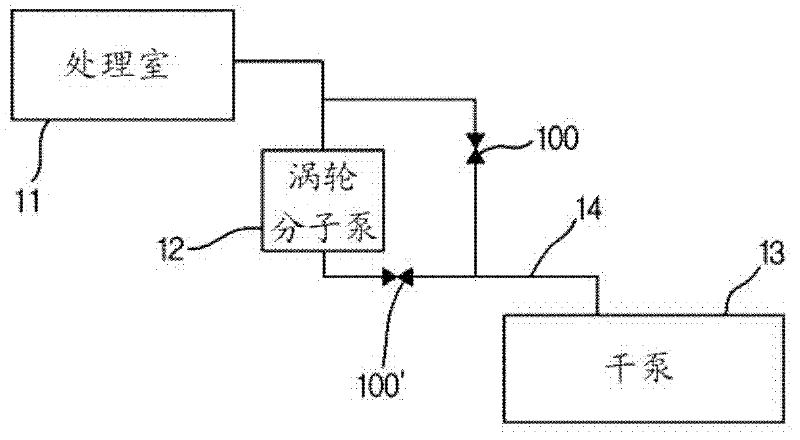

[0028] figure 1 is a schematic block diagram of a vacuum system using a valve for a vacuum process according to an exemplary embodiment. figure 1 A process chamber 11 , a turbomolecular pump (TMP) 12 and a dry pump 13 are shown.

[0029] When the gas in the chamber is energized to become a plasma state, a reaction occurs in the wafer in the chamber and a thin film is formed on the wafer. Excess reactants generated in the thin film forming process are discharged through the turbomolecular pump 12 and the pipe 14 . A first valve 100 for a vacuum process is installed between the process chamber 11 and the dry pump 13 . A second valve 100' for the vacuum process is installed downstream of the turbomolecular pump. The first valve 100 for a vacuum process may also be called an "isolation valve". The second valve 100' fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com