Monomer deposition apparatus

A single monomer deposition and equipment technology, applied in the direction of electric solid devices, semiconductor devices, devices for coating liquid on the surface, etc., can solve the problems of shortened life cycle, increased maintenance cost, increased manufacturing cost, etc., to improve productivity and prolong Effects of maintenance cycle and manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] Hereinafter, the present invention will be described more fully with reference to the accompanying drawings. Likewise, descriptions of well-known functions and configurations can be omitted to increase clarity and conciseness. The exemplary embodiments of the present invention described herein will be thought of by those skilled in the art. In the drawings, the sizes and relative sizes of layers and regions may be exaggerated for clarity.

[0018] Exemplary embodiments of the monomer deposition apparatus will be described in detail with reference to the accompanying drawings.

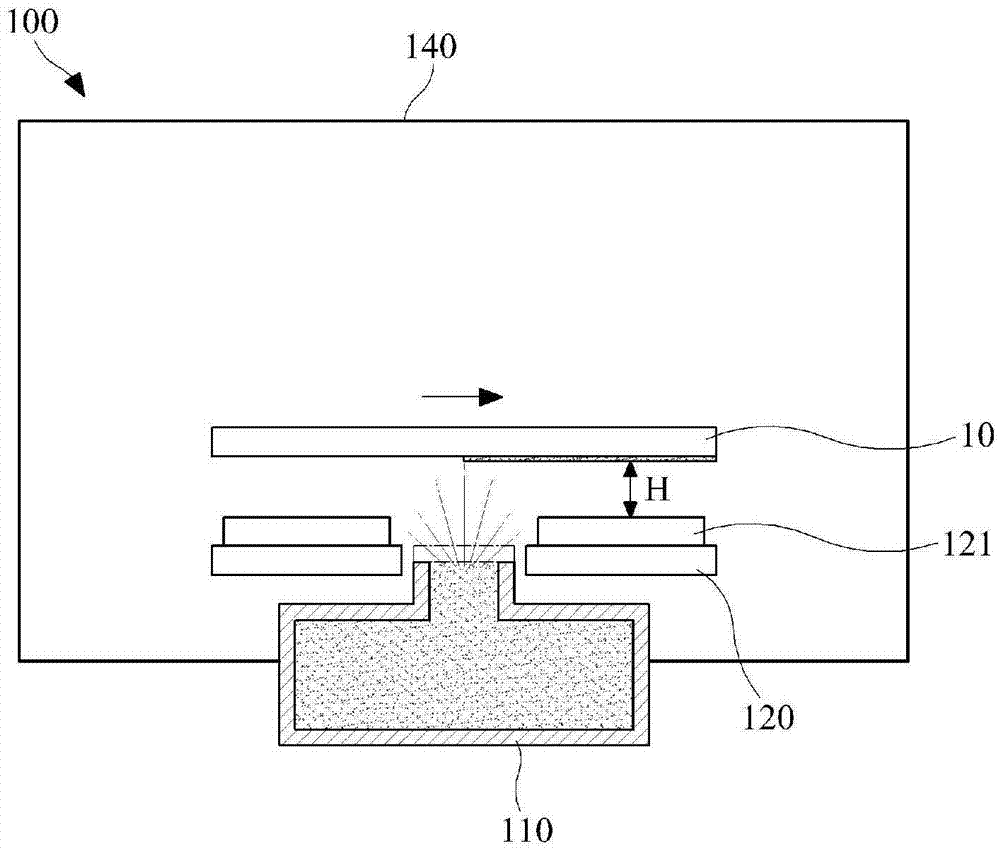

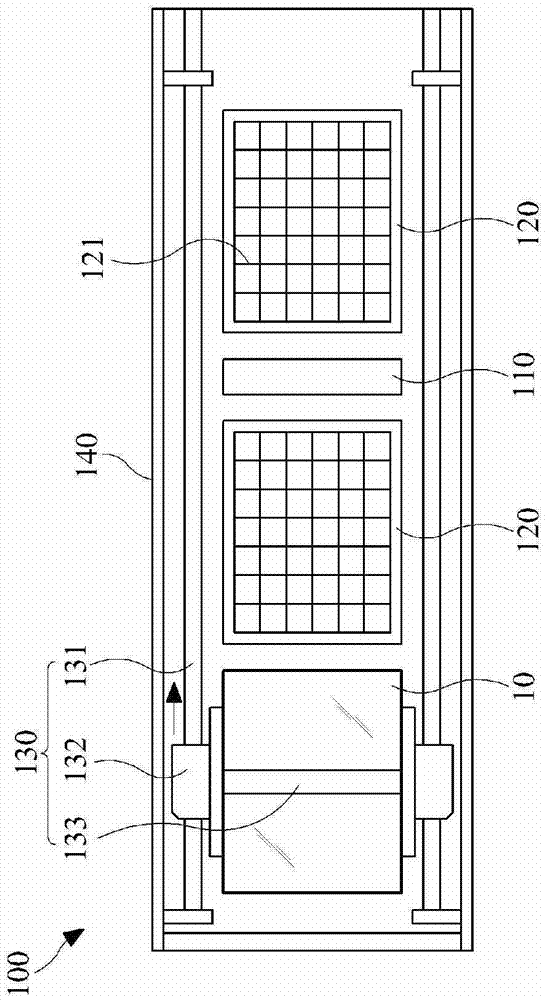

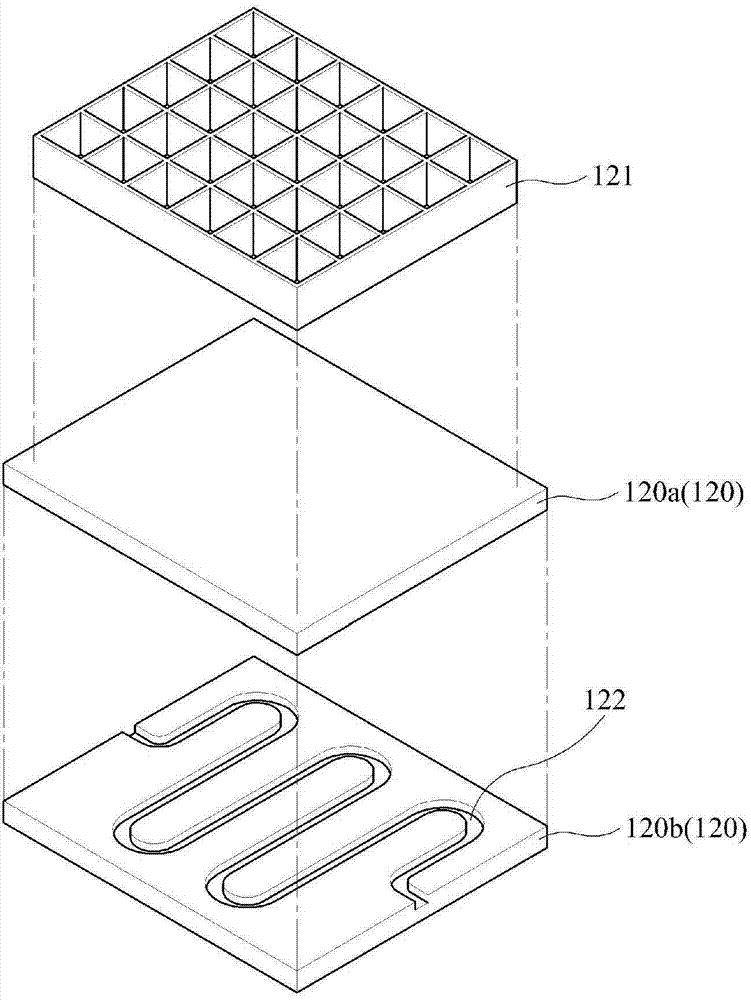

[0019] reference figure 1 with figure 2 , The monomer deposition apparatus 100 includes a chamber 140, a deposition unit 110, and a cooling plate 120.

[0020] The chamber 140 includes a processing space in which the substrate 10 can be accommodated, and the monomer is to be deposited in the substrate. The cavity 140 may be in the shape of a cylinder or a hexahedron. However, the shape of the cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com