Heat pipe with grooves

A heat pipe and grooved technology, applied in the field of grooved heat pipes, can solve the problems that the efficiency of sintered heat pipes cannot be achieved, the working liquid channel of the finished heat pipe becomes smaller, and the advantage of low cost cannot be expanded, so as to reduce heat conduction The resistance value, the specific surface area of the powder increase, and the effect of improving the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

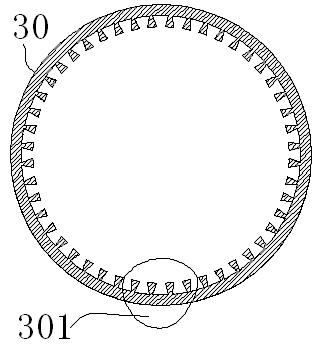

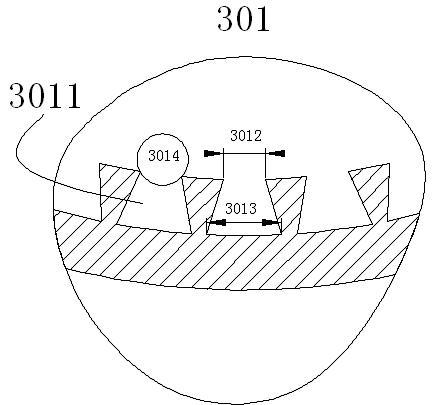

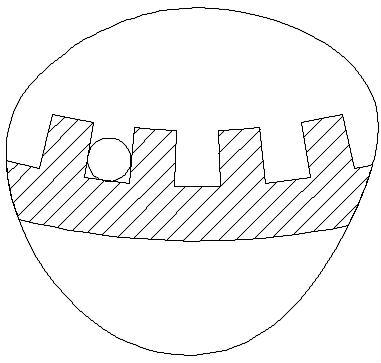

[0024] see figure 1 , Figure 5 As shown, a grooved heat pipe includes a pipe body 30, the inner wall of the pipe body 30 is provided with a plurality of groove structures in the radial direction as a working fluid circuit 3011, and the pipe body 30 is filled with copper powder Particles 3014 are sintered to form a copper powder layer. The cross-section of the groove structure is a trapezoidal structure. The width of the top 3012 of the groove structure is smaller than the width of the bottom 3013 of the groove, and the top 3012 of the groove is The width is smaller than the average particle diameter of the copper powder particles 3014.

[0025] Preferably, the average width dimension from the slot top 3012 to the slot bottom 3013 of the groove structure is ≥ the average particle diameter of the copper powder particles 3014 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com