Heat dissipation module

A technology of heat dissipation module and heat pipe, which is used in cooling/ventilation/heating transformation and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0057] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

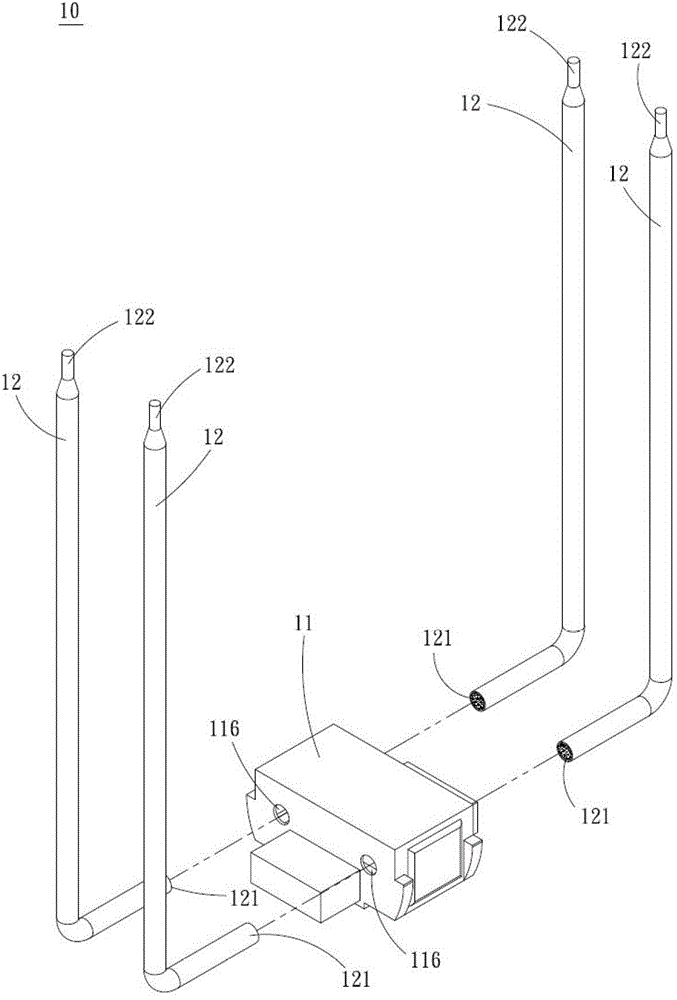

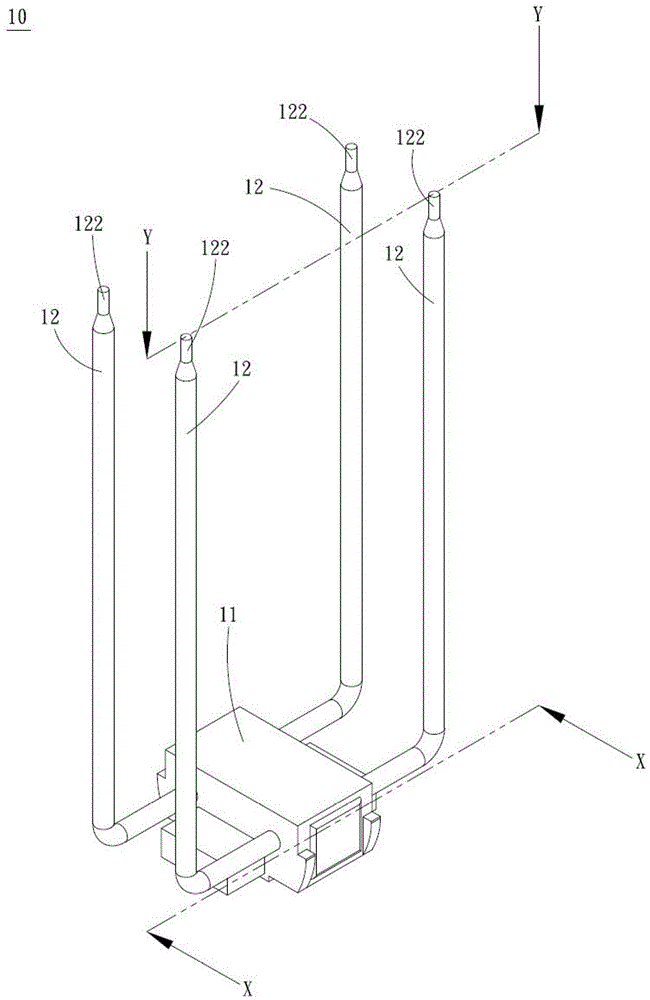

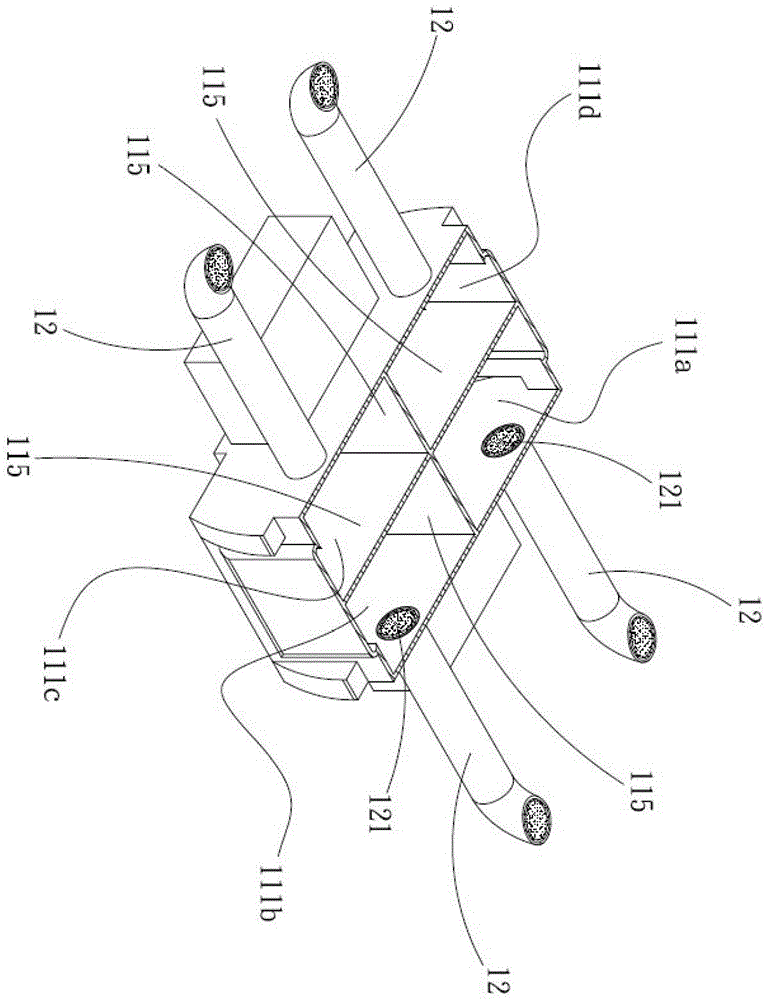

[0058] see Figures 1 to 4 , figure 1 It is a three-dimensional exploded schematic diagram of the present invention, figure 2 It is a three-dimensional combination schematic diagram of the present invention, image 3 for the invention figure 2 The cross-sectional view of the X-X line, Figure 4 for the invention figure 2 The profile of the Y-Y line. Such as Figures 1 to 4 As shown, the heat dissipation module 10 includes a casing 11, and the casing 11 includes a plurality of casing chambers 111a-111d that are independent from each other. An open end of at least one heat pipe is communicated with, and the open end is communicated with a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com