Calibration device of large weighing apparatus

A weighing instrument and large-scale technology, which is applied in the field of verification structure of large weighing instruments, can solve the problems of time-consuming and labor-intensive verification, insufficient accuracy, and huge verification workload, and achieves a simple structure, saves costs, and improves work efficiency and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

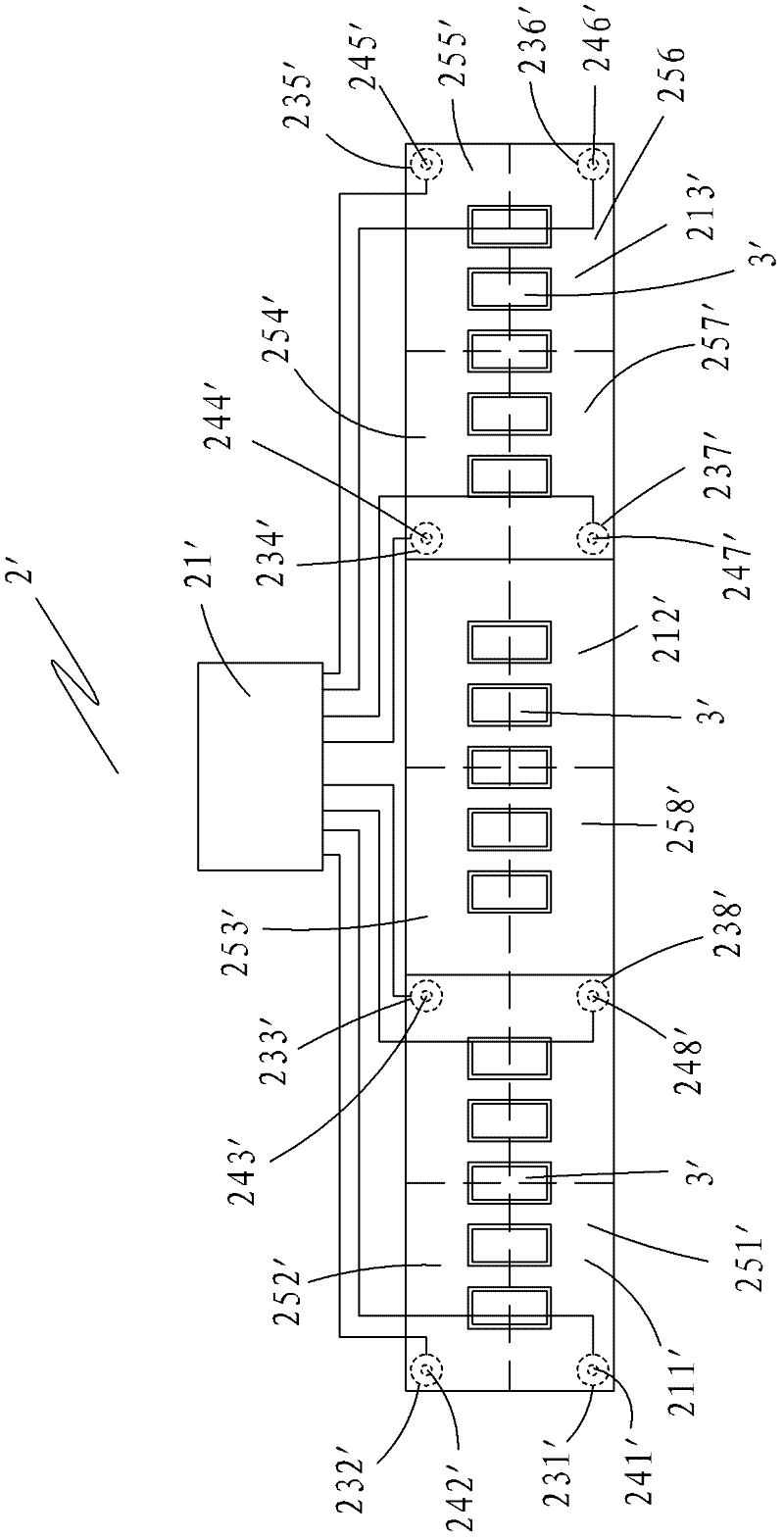

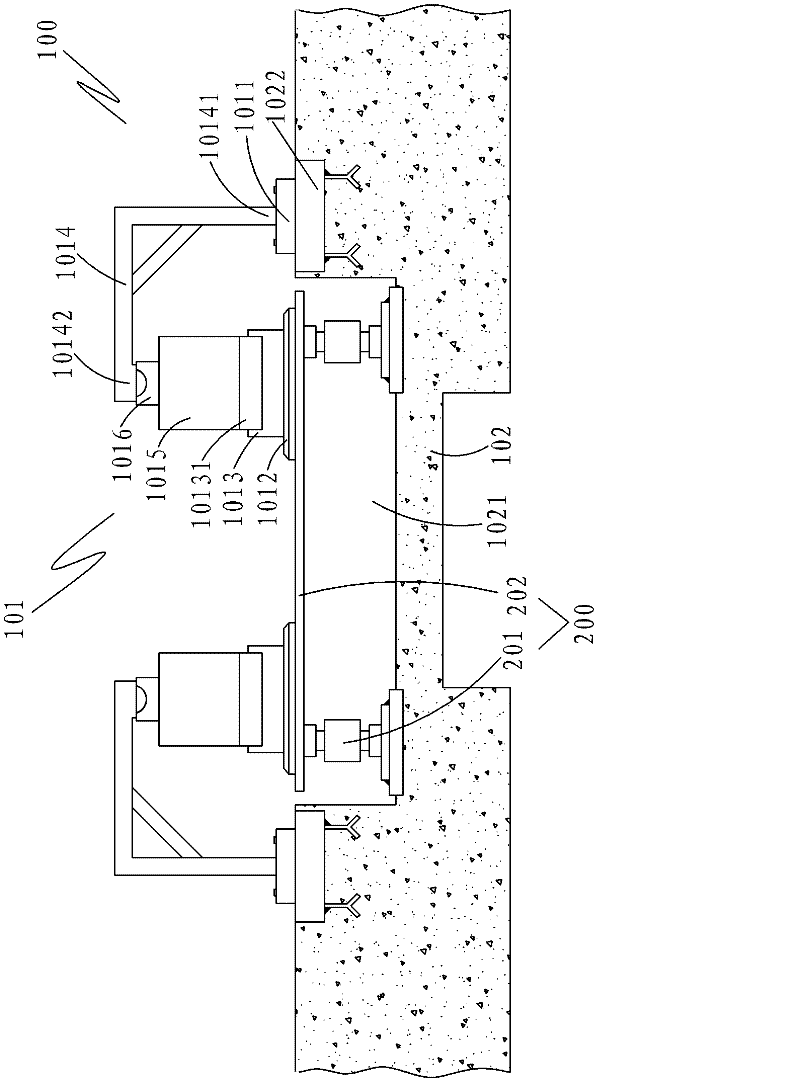

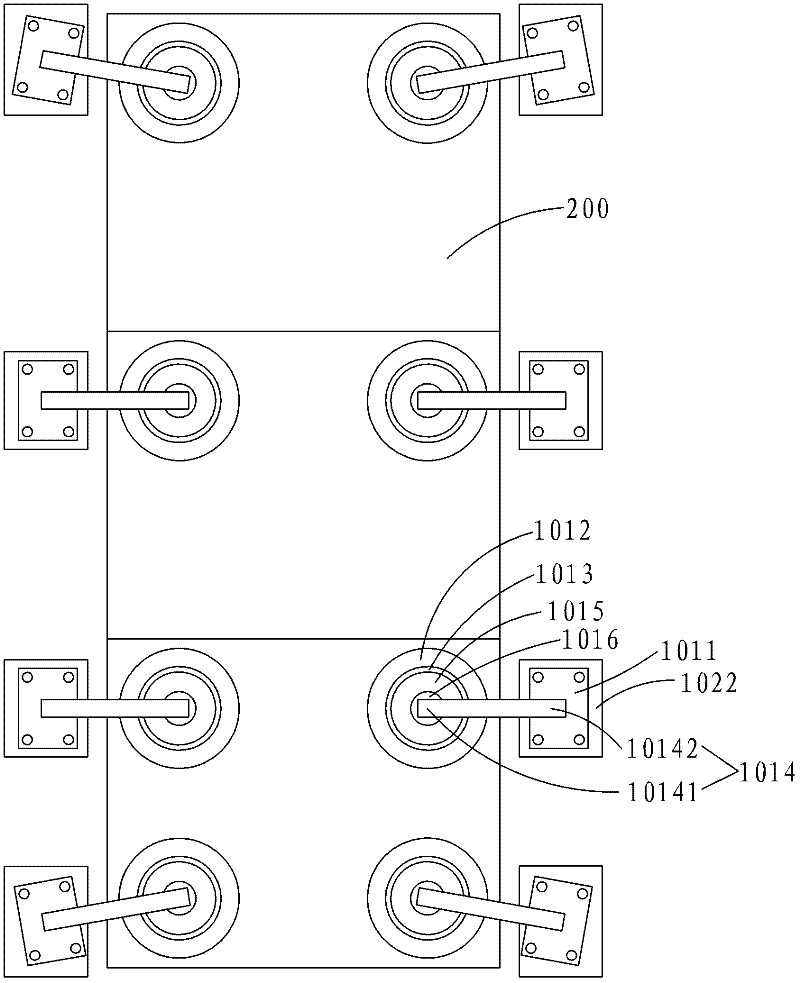

[0036] Please refer to figure 2 and Figure 4 , a verification structure 100 of a large-scale weighing apparatus according to the present invention, comprising at least verification units 101 consistent with the number of load cells 201 of the weighing apparatus 200 under test and a foundation 102 for supporting each verification unit 101, on which a The foundation pit 1021 for accommodating the weighing apparatus 200 under test, and the foundation 102 on both sides of the foundation pit 1021 are respectively provided with foundation embedded boards 1022; each verification unit 101 includes a foundation embedded board 1022 Base 1011, a pair of booster cylinders 1013 centered on a pressure bearing plate 1012, a cantilever beam 1014 including a fixed end 10141 and a free end 10142, a force sensor 1015, and a pair centered on the force sensor 1015 The ball head pressure block 1016, the pressure bearing plate 1012 is placed on the weighing platform 202 of the weighing instrument...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com