Sensitive differential pressure sensor and method

A differential pressure sensor, sensor technology, used in instruments, measuring fluid pressure, piston-type fluid pressure measurement, etc., can solve the problems of high cost and not fully suitable for measuring low differential pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following detailed description of the exemplary embodiments refers to the accompanying drawings. The same reference numbers in different drawings identify the same or similar elements. Furthermore, the following detailed description is not intended to limit the invention. Rather, the scope of the invention is defined by the appended claims.

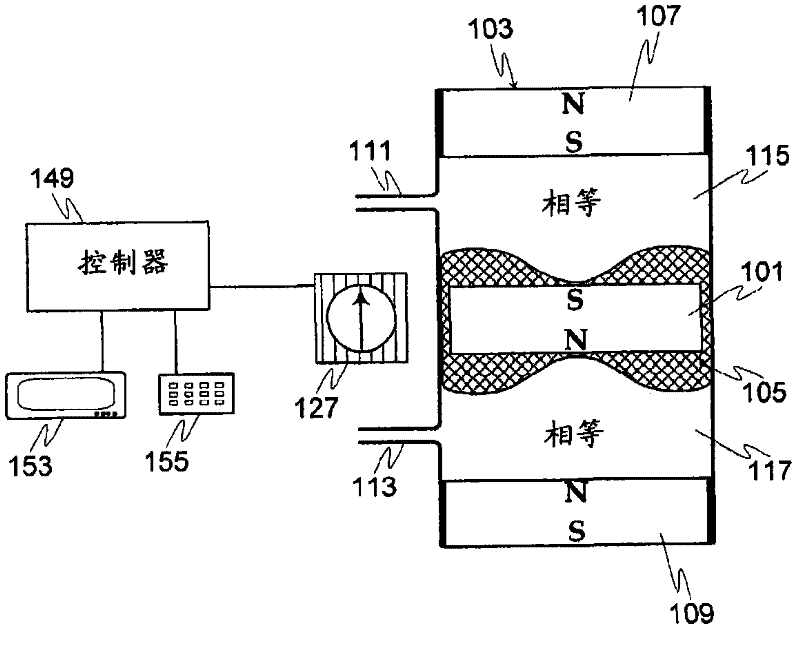

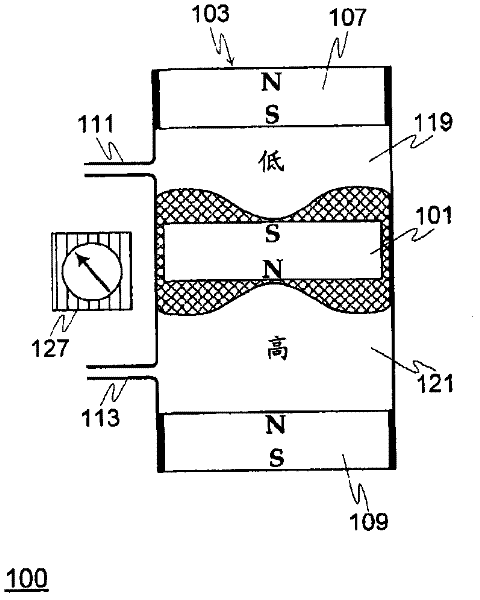

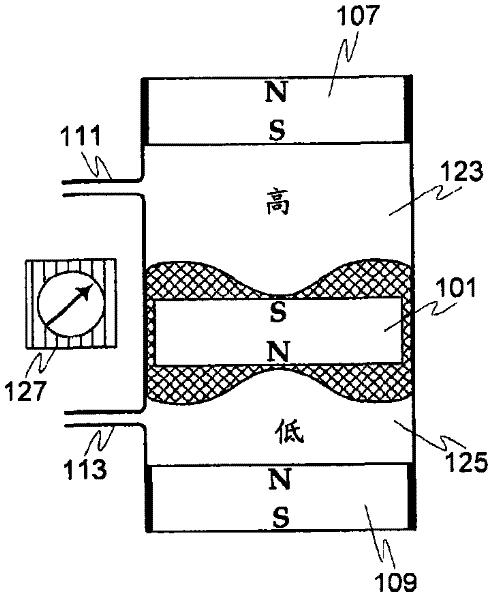

[0012] Figure 1A -C shows a cross-sectional view of the differential pressure sensor 100 according to an embodiment of the present invention. Various embodiments disclosed herein relate to differential pressure transducers that use one or more permanently magnetized moving pistons contained in a barrel and stationary magnets sealed into the end of the barrel. The barrel can be made of a material that has low magnetic permeability, is transparent to the magnetic flux lines, but is able to withstand the measured pressure. The movable piston 101 is sealed into the barrel 103 using a ferrofluid 105 that provides an extremely lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com