Mooring chain fatigue strength testing method

A technology of fatigue strength and test method, which is applied in the direction of testing the strength of materials by applying repetitive force/pulsation force, and can solve the problem of no test method being proposed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The present invention will be further described below in conjunction with accompanying drawing:

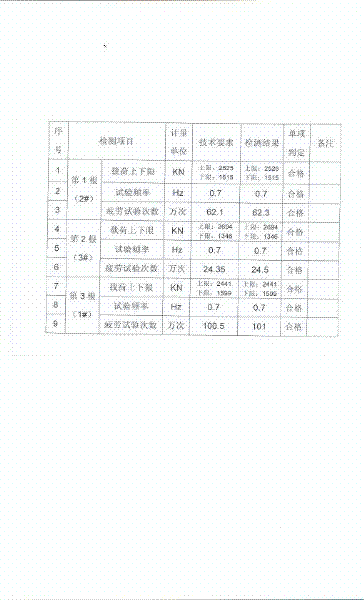

[0007] The test method for the fatigue strength of mooring chains is characterized in that: one test needs to include three groups of samples, consisting of 7 common mooring chain links, 3 for routine tests, and the rest for supplementary tests after test failures; At least 6 Kent shackles or 6 D-type shackles for each loading test; all samples including connectors must be numbered and cannot be marked in the bending ring area; all samples including connectors must be in accordance with the requirements of the classification society Carry out mechanical tests, and the test results must meet the requirements of the classification society; all samples, including connectors, need to be inspected visually, magnetic particle and ultrasonic after the tensile test and cleaning, and the inspection results must meet the relevant requirements of the classification society; Before, al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com