System for measuring pressure response time of pressure sensitive paint by shock wave method

A technology of pressure-sensitive coating and response time, which is applied in the direction of material excitation analysis, fluorescence/phosphorescence, etc., to achieve the effect of convenient comparison and simple collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

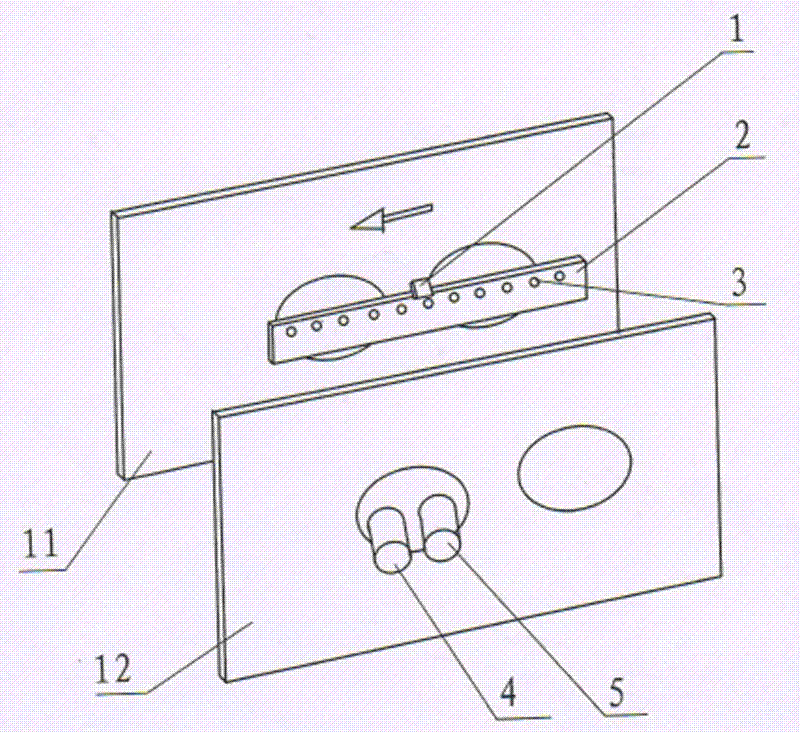

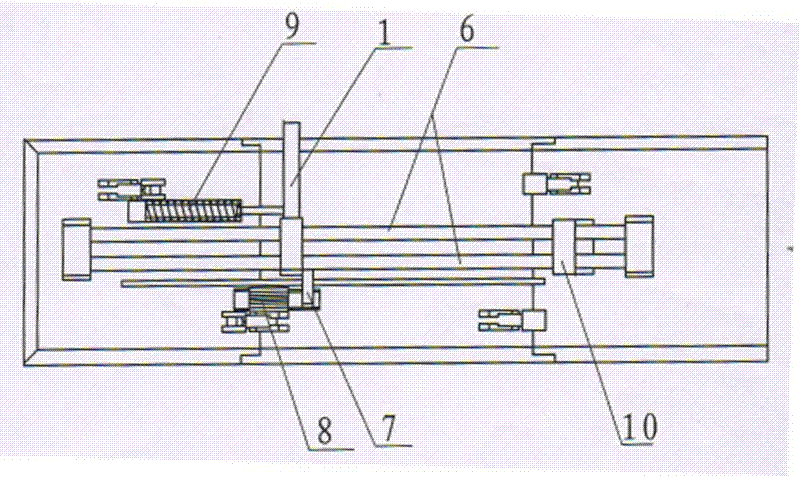

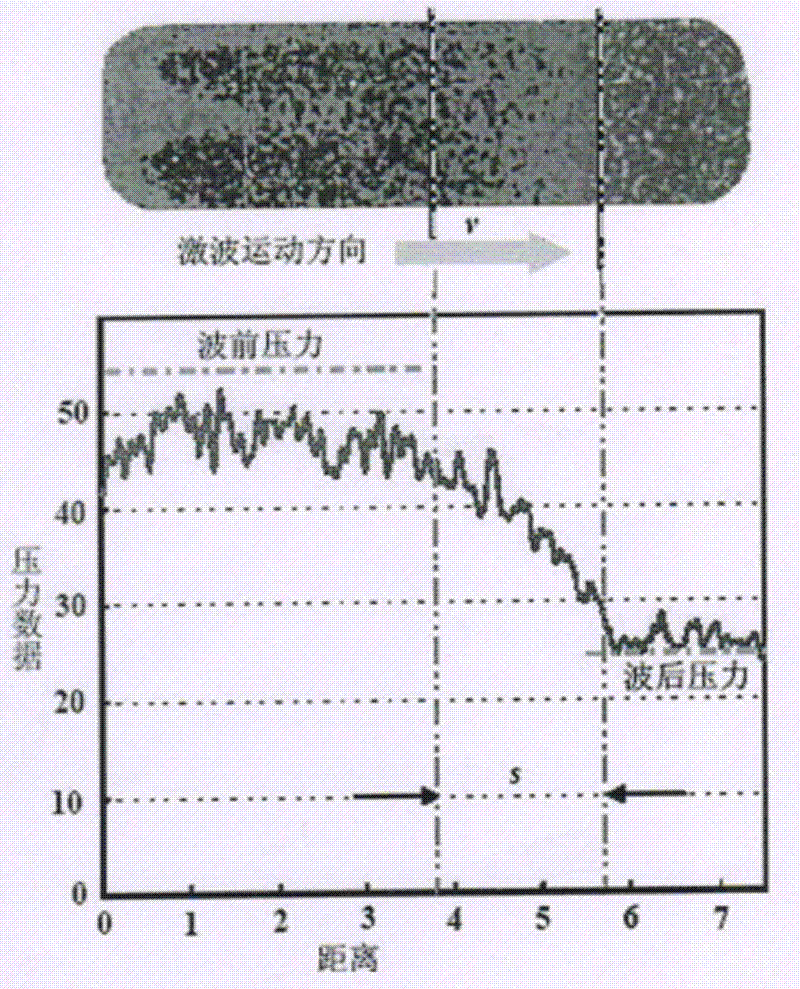

[0020] Shock wave method pressure-sensitive paint pressure response time measurement system, including a shock wave generator 1, a test piece test plate 2 for spraying pressure-sensitive paint, and an element dynamic pressure sensor for detecting the speed of the shock wave sweeping across the test plate 3. Light source UV flash lamp for generating excitation light 4, equipment CCD camera for collecting pressure-sensitive paint images 5, shock wave generator running track slider 6, component stopper for blocking shock wave generator movement before the test 7. The driving motor of the power equipment used to remove the stopper of the shock wave generator during the test test. The component spring 9 that makes the shock wave generator generate an initial speed is used to decelerate the shock wave generator and make it slow down at the end of the test. Component shock absorber 10 for stopping motion. The test plate 2 is sprayed with the pressure-sensitive paint to be tested, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com