Micro-mirror graph scanning mechanism

A graphic scanning and micromirror technology, used in medical science, optics, instruments, etc., to achieve the effects of high safety, low power consumption, and simple optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is an embodiment of a thermally driven micromirror of the micromirror pattern scanning mechanism.

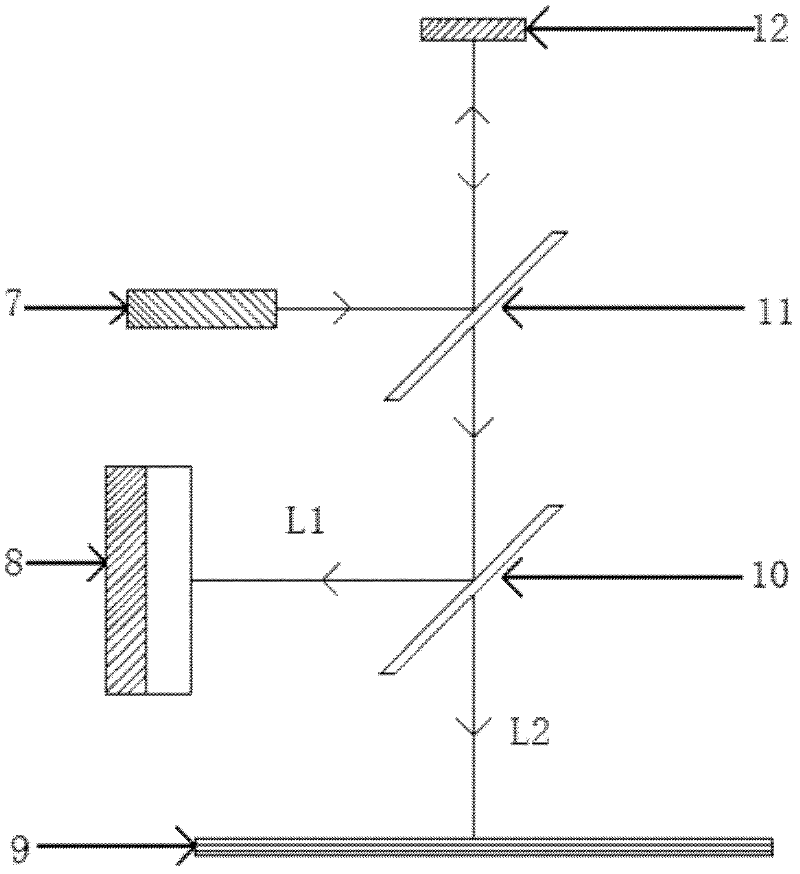

[0043] Such as figure 2 The optical path is constructed in a manner, and the optical path structure includes a laser light source 7 , two optical mirrors, a heat-driven micromirror device 12 and a screen 9 . The laser light source 7 is divided into two laser beams after passing through the first beam splitter 11, one beam is hit on the heat-driven micromirror device system 12, and the other beam is hit on the second beam splitter 10, and the two beams of light separated by the second beam splitter are one One beam hits the position sensitive sensor PSD 8 and one hits the screen 9 .

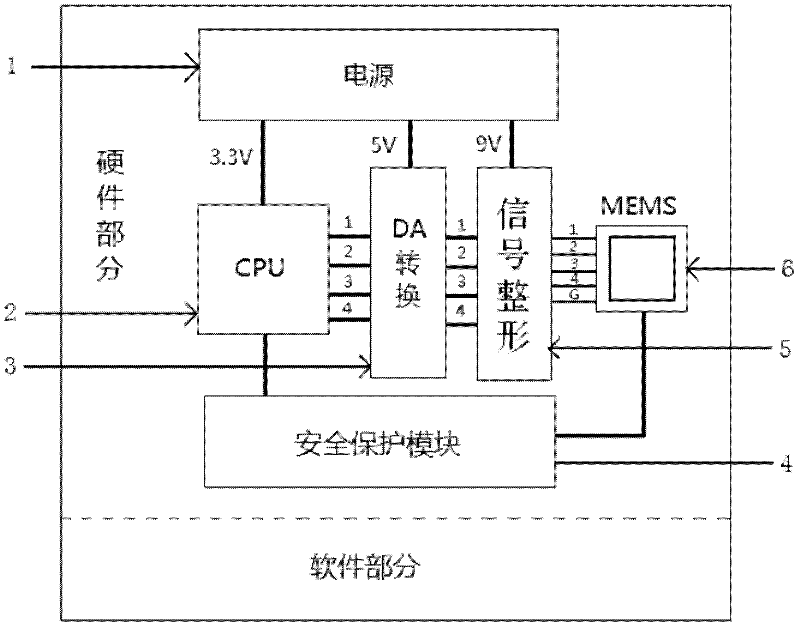

[0044] To realize optical scanning, the drive circuit must first generate an analog drive signal. The block diagram of the entire thermally driven micromirror device 12 system is shown in figure 1 As shown, the driving circuit includes a central processing unit 2 , a digital-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com