Vertical alignment LCD (liquid crystal display) and driving method thereof

A liquid crystal display, vertical alignment technology, applied in its drive field, can solve problems such as image sticking, and achieve the effect of improving image sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

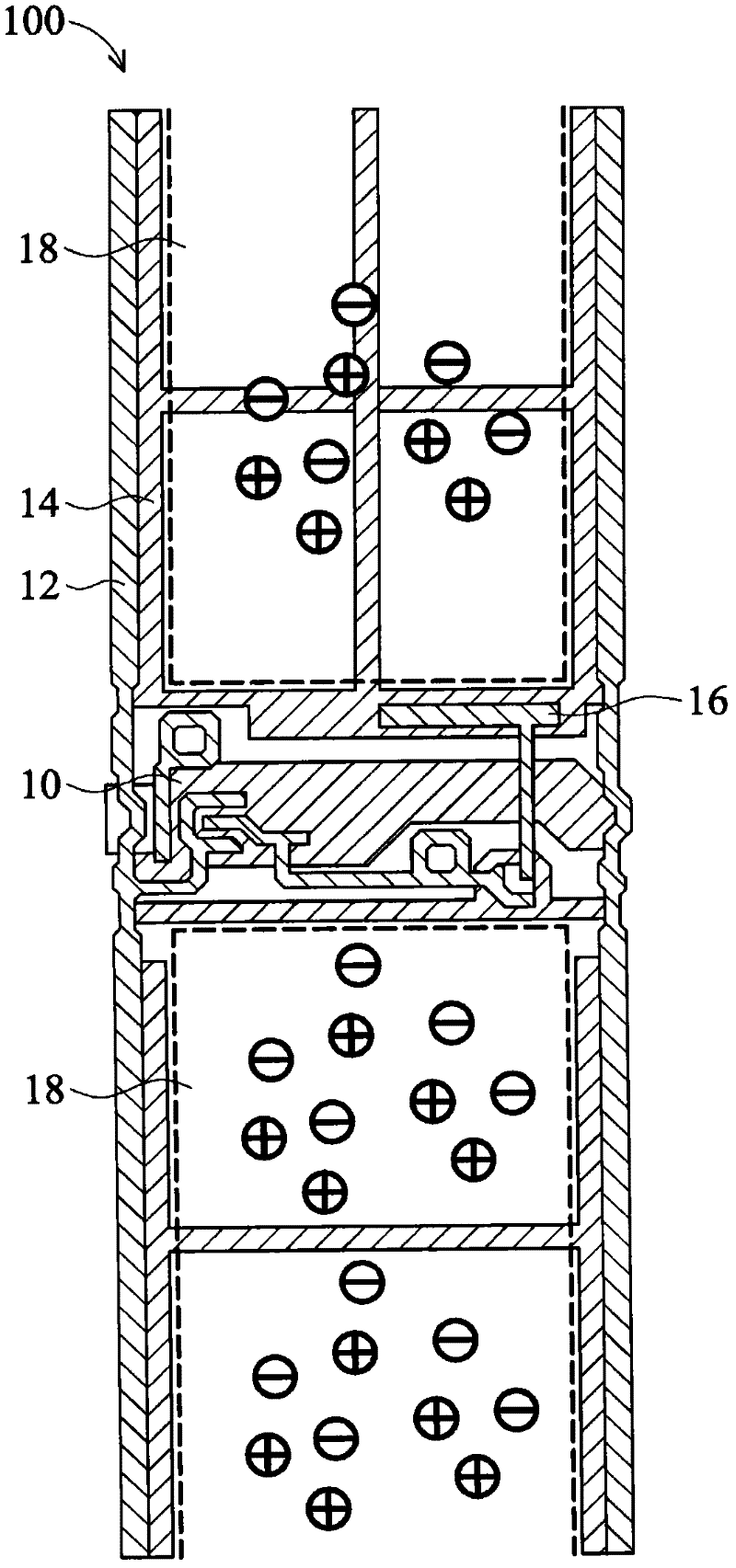

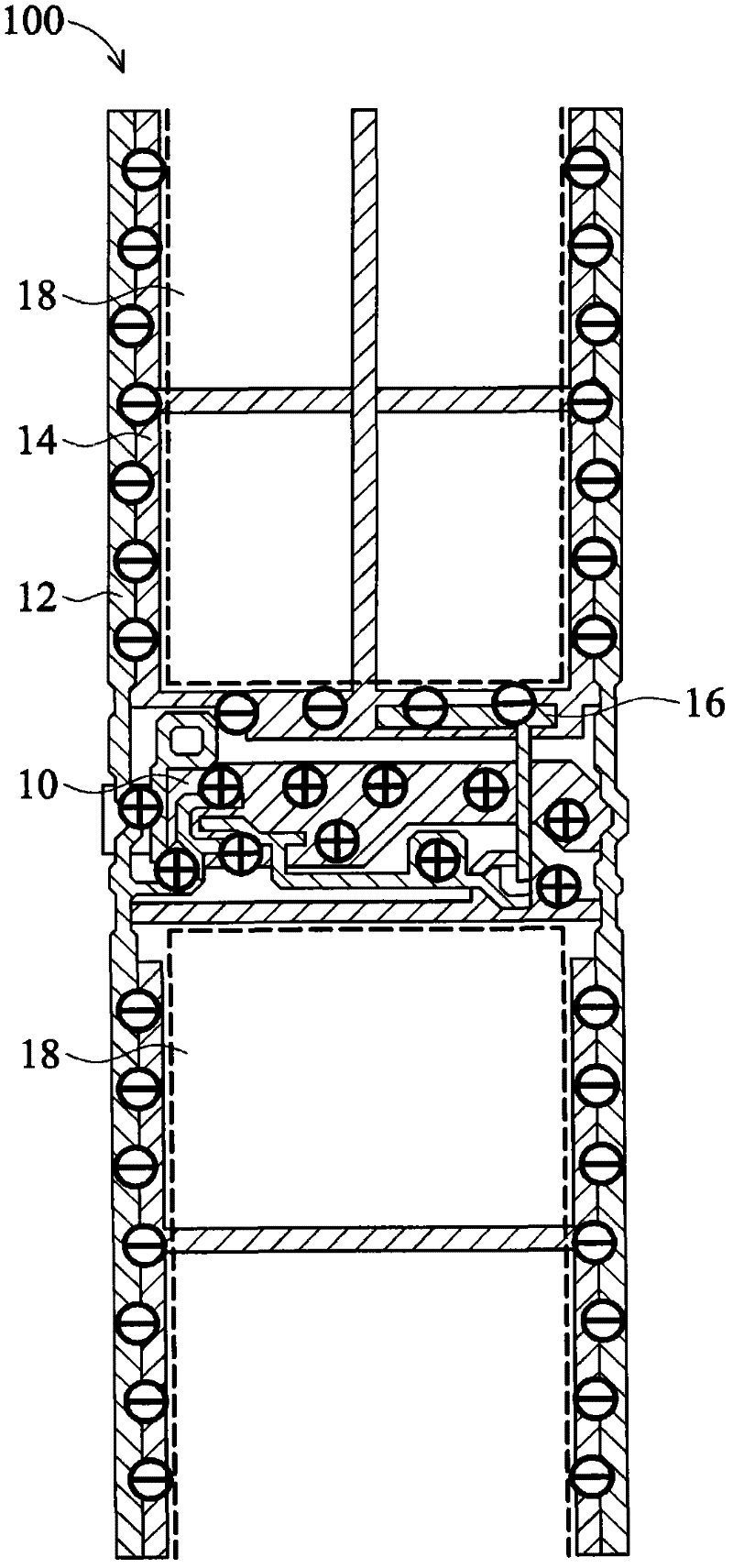

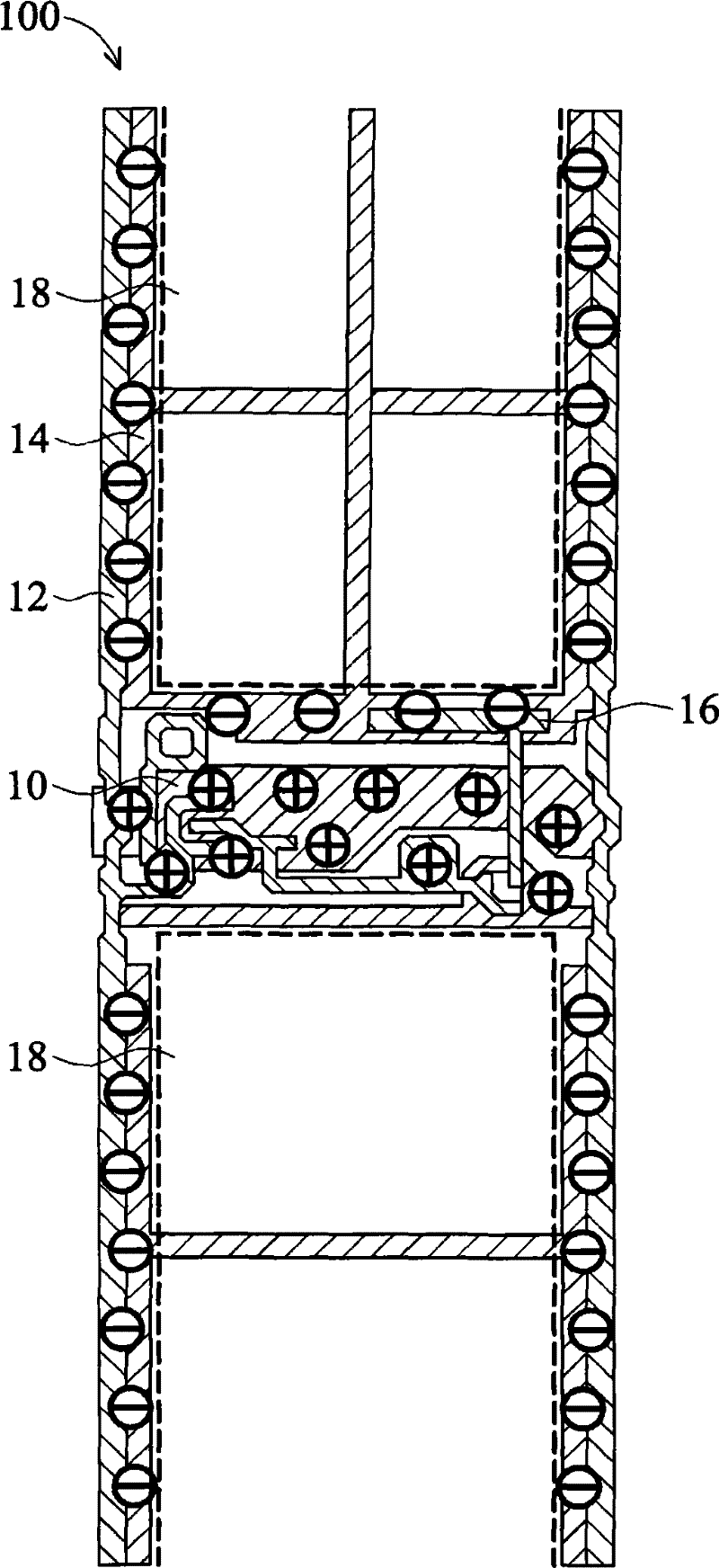

[0014] Such as figure 1 As shown, it is a partial top view of the array substrate 100 according to an embodiment of the present invention. The array substrate 100 includes a gate line 10 connected to the gate of the thin film transistor, a data line 12 connected to the source of the thin film transistor, and a common line 14 serving as the bottom electrode of the storage capacitor 16 . The gate line 10 and the data line 12 vertically intersect to define a pixel area 18 . The above-mentioned array substrate 100 can be matched with a color filter substrate (not shown), and a liquid crystal layer (not shown) is interposed therebetween to form a vertical alignment liquid crystal display. The above-mentioned liquid crystal layer can be a common nematic liquid crystal material to meet the requirement of vertical alignment. In an embodiment of the present invention, the threshold voltage of the liquid crystal layer may be between 100 mV and 1500 mV, depending on the circuit layout ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com